The merits of LED strip lighting in underground mining

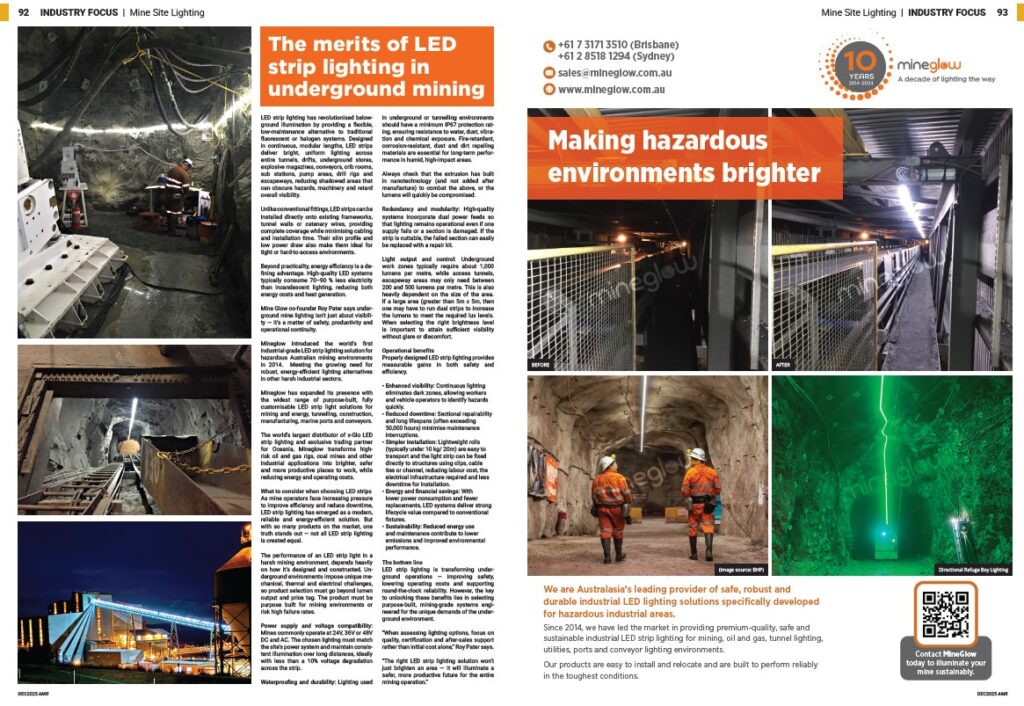

LED strip lighting has revolutionised below-ground illumination by providing a flexible, low-maintenance alternative to traditional fluorescent or halogen systems. Designed in continuous, modular lengths, LED strips deliver bright, uniform lighting across entire tunnels, drifts, underground stores, explosive magazines, conveyors, crib rooms, sub stations, pump areas, drill rigs and escapeways, reducing shadowed areas that can obscure hazards, machinery and retard overall visibility.

Unlike conventional fittings, LED strips can be installed directly onto existing frameworks, tunnel walls or catenary wires, providing complete coverage while minimising cabling and installation time. Their slim profile and low power draw also make them ideal for tight or hard-to-access environments.

Beyond practicality, energy efficiency is a defining advantage. High-quality LED systems typically consume 70–90 % less electricity than incandescent lighting, reducing both energy costs and heat generation.

Mine Glow co-founder Roy Pater says underground mine lighting isn’t just about visibility — it’s a matter of safety, productivity and operational continuity.

Mineglow introduced the world’s first industrial-grade LED strip lighting solution for hazardous Australian mining environments in 2014. Meeting the growing need for robust, energy-efficient lighting alternatives in other harsh industrial sectors.

Mineglow has expanded its presence with the widest range of purpose-built, fully customisable LED strip light solutions for mining and energy, tunnelling, construction, manufacturing, marine ports and conveyors.

The world’s largest distributor of x-Glo LED strip lighting and exclusive trading partner for Oceania, Mineglow transforms high-risk oil and gas rigs, coal mines and other industrial applications into brighter, safer and more productive places to work, while reducing energy and operating costs.

What to consider when choosing LED strips

As mine operators face increasing pressure to improve efficiency and reduce downtime, LED strip lighting has emerged as a modern, reliable and energy-efficient solution. But with so many products on the market, one truth stands out — not all LED strip lighting is created equal.

The performance of an LED strip light in a harsh mining environment, depends heavily on how it’s designed and constructed. Underground environments impose unique mechanical, thermal and electrical challenges, so product selection must go beyond lumen output and price tag. The product must be purpose built for mining environments or risk high failure rates.

Power supply and voltage compatibility: Mines commonly operate at 24V, 36V or 48V DC and AC. The chosen lighting must match the site’s power system and maintain consistent illumination over long distances, ideally with less than a 10 % voltage degradation across the strip.

Waterproofing and durability: Lighting used in underground or tunnelling environments should have a minimum IP67 protection rating, ensuring resistance to water, dust, vibration and chemical exposure. Fire-retardant, corrosion-resistant, dust and dirt repelling materials are essential for long-term performance in humid, high-impact areas.

Always check that the extrusion has built in nanotechnology (and not added after manufacture) to combat the above, or the lumens will quickly be compromised.

Redundancy and modularity: High-quality systems incorporate dual power feeds so that lighting remains operational even if one supply fails or a section is damaged. If the strip is cuttable, the failed section can easily be replaced with a repair kit.

Light output and control: Underground work zones typically require about 1,000 lumens per metre, while access tunnels, escapeway areas may only need between 200 and 500 lumens per metre. This is also heavily dependent on the size of the area. If a large area (greater than 5m x 5m, then one may have to run dual strips to increase the lumens to meet the required lux levels. When selecting the right brightness level is important to attain sufficient visibility without glare or discomfort.

Operational benefits

Properly designed LED strip lighting provides measurable gains in both safety and efficiency.

- Enhanced visibility: Continuous lighting eliminates dark zones, allowing workers and vehicle operators to identify hazards quickly.

- Reduced downtime: Sectional repairability and long lifespans (often exceeding 50,000 hours) minimise maintenance interruptions.

- Simpler installation: Lightweight rolls (typically under 10 kg/ 20m) are easy to transport and the light strip can be fixed directly to structures using clips, cable ties or channel, reducing labour cost, the electrical infrastructure required and less downtime for installation.

- Energy and financial savings: With lower power consumption and fewer replacements, LED systems deliver strong lifecycle value compared to conventional fixtures.

- Sustainability: Reduced energy use and maintenance contribute to lower emissions and improved environmental performance.

LED strip lighting is transforming underground operations — improving safety, lowering operating costs and supporting round-the-clock reliability. However, the key to unlocking these benefits lies in selecting purpose-built, mining-grade systems engineered for the unique demands of the underground environment.

“When assessing lighting options, focus on quality, certification and after-sales support rather than initial cost alone,” Roy Pater says.

“The right LED strip lighting solution won’t just brighten an area — it will illuminate a safer, more productive future for the entire mining operation.”