Fortescue green metal project boosted by Metso

Fortescue (ASX: FMG) has incorporated Metso technology to support low-emission steelmaking at its Christmas Creek green metal project, currently under construction in the Pilbara, WA.

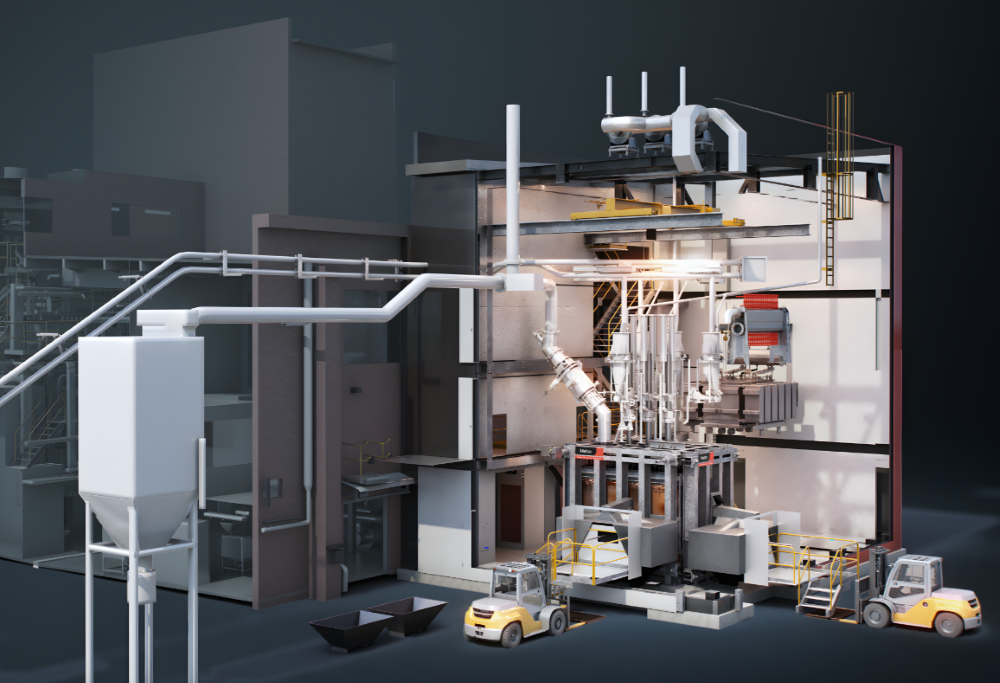

The $75m [US$50m] project will demonstrate the production of high-purity green metal using renewable energy for hydrogen-based reduction and smelting technologies for further downstream steel processing using Metso’s Circored fluidised bed direct reduction process and an electric direct reduced iron (DRI) smelting furnace.

Green hydrogen produced at Fortescue’s gaseous and liquid hydrogen facility, the largest of its kind in Australia, together with an electric smelting furnace to produce high purity green metal will be used at Christmas creek.

Fortescue metals and operations chief executive Dino Otranto says green metal presents a huge opportunity for Australia’s iron ore industry and Fortescue is determined to lead the way.

“Through the Christmas Creek green metal project, we’re combining cutting-edge technologies, including Metso’s Circored process and DRI Smelting Furnace, with Fortescue’s proven track record in project delivery, to pioneer low-emission pathways for steelmaking,” he said.

This initial project will have an annual output of more than 1500t, with studies underway to support development of a commercial-scale facility.

Traditional blast furnace operations account for about 90% of the steel sectors carbon emissions globally, producing about 2.3t of carbon dioxide for every tonne of crude steel, according to Steel Watch.

Combined with the rising pressures to lower emissions, this creates substantial global market opportunities for zero-emission alternatives.

Metso smelting vice president Jyrki Makkonen says the low-emission electric smelting (ESF)-based steelmaking route, which substitutes traditional blast furnaces in the production of hot metal, is well-suited for Australia’s abundant, low-to-medium-grade Pilbara iron ores.

“The ambitious target for the Metso DRI Smelting furnace technology is to unlock utilisation of these massive iron ore reserves for green iron making, when such iron ores previously have been not suitable for the DRI steelmaking route due to higher gangue content,” he said.