From tank to tank farm

In 2001, DRA Group delved into tank engineering and recruited personnel with experience in the design and build of steel tanks before becoming a member of the Steel Tank Institute (STI), allowing it to manufacture the entire range of STI accredited tanks.

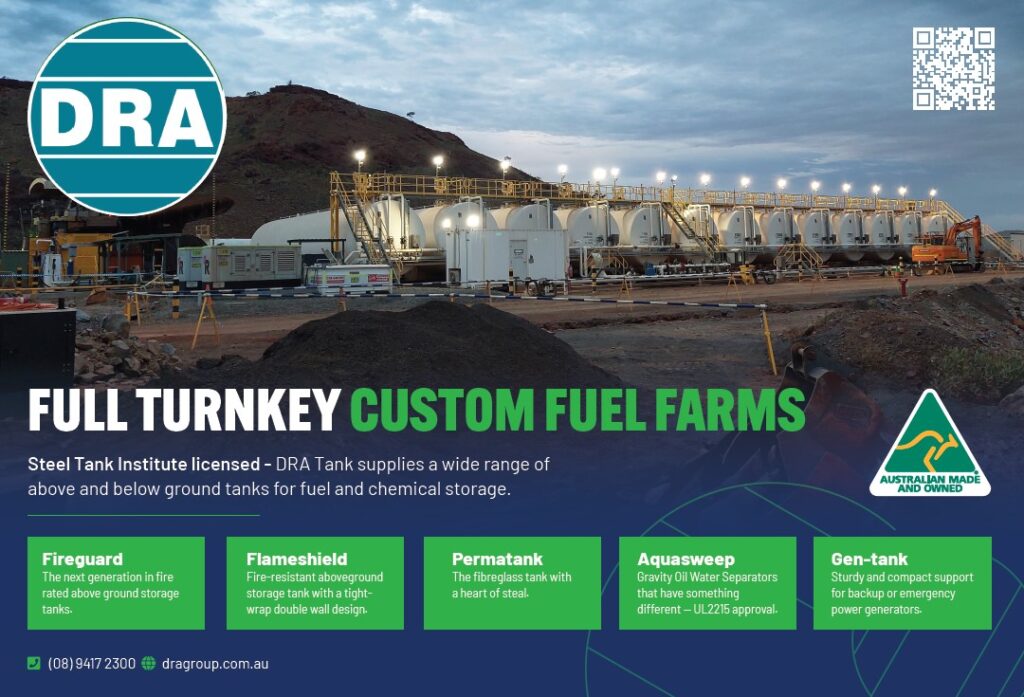

DRA Tank supplies a wide range of above and below ground tanks for fuel and chemical storage, including for major companies Shell and BP. Full turnkey custom fuel farms can be designed and installed by DRA’s team of experienced engineers.

DRA Tank is a total fuel system supplier — above and below ground fuel and chemical storage tanks, site-built tanks, site installations and pumping system design can all be handled by its in-house design team. Being the only tank fabricator with its own abrasive blasting and coating division ensures the tanks are of the highest quality.

All manufacturing is subject to third party inspection in accordance with DRA’s STI License. DRA has been awarded by STI the 2024 Quality Award for 12 consecutive years of top quality.

DRA recently supplied one of the largest tank farms consisting of 2,400,000L with tanks 18m long, 4m diameter weighing 30t each.

DRA Tank has established itself as the supplier of preference for mine-site storage by various installers with a storage and distribution facility designed by consultants.

Previous distribution facilities were poorly designed and failed to meet the required fill capacity — often with poor reliability and inadequate filtration. To address the problem, DRA began supplying single tanks up to 200kL with inbuilt pumping, data collection, filtration and filling included as a complete solution.

Flameshield

The Flameshield design is a fire-resistant double wall tank tested in the US by the accredited Southwest Research Institute up to 2 hours at 1100oC. Flameshield Tanks are supplied to all mine-site projects storing diesel and oil ranging in all sizes up to 250kL. All tanks are entered on the STI international data base for traceability.

Fireguard

Fireguard tanks are fabricated with an outer steel wall that won’t crack like concrete. The unique thermal insulation is 75% lighter than concrete and sufficiently porous enough to facilitate quick emergency venting and/or leak detection. Fireguard are usually for storage of diesel used to operate generators used for backup power when power from the grid fails.

Permatank

Permatank is a double walled jacketed underground tank consisting of the inner steel tank with corrosion resistant fibreglass outer skin. The leak detection system monitoring the vacuum guarantees no product leakage. Each Permatank is supplied with a 30-year warranty ensuring a lifetime of trouble-free storage.

AquaSweep

AquaSweep removes non emulsified oils and related petroleum products from stormwater runoff down to 5 ppm. Available in single and double wall design. Tested to UL 2215 and ULC-S656 and meets the US EPA clean water act. Range available to match run off flow rates.

Gen-Tank

Gen-Tank provides sturdy support for backup and emergency power generators. The low-profile design of the Gen-Tank serves as structural support for the generator mounting. Construction tested to UL2085 and fire-resistant construction tested to SwRI 97-04.

DRA Tank has designed, manufactured, delivered and commissioned fuel facilities, including a 200kL x 20 tank fuel farm for Fortescue and a 100kL x 4 tank fuel facility for Rio Tinto servicing a 1000 man camp,, on time and within budget. The next stage of DRA Tank’s development is offering contracts for servicing and maintaining commissioned facilities.

DRA Tank does much more than simply supply — its team offers a true turnkey solution by designing and commissioning a tank farm catering to unique operational needs.