The geosynthetic lined facilities specialists

Since 2017, GeoQ has been delivering industry-leading Electrical Leak Detection (ELD) services for some of Australia’s largest tailings storage facilities — helping major miners verify liner integrity and prevent costly failures before commissioning.

Using advanced geosynthetic materials and deep-rooted expertise, we are not just meeting the needs of today but are also building enduring, environmentally sound practices for the prosperity of its global geosynthetic industry.

GeoQ’s unique position as Australia’s sole truly independent provider of construction quality assurance (CQA) and electrical leak detection services for geosynthetic installations underlines our mission to guarantee industry compliance and uphold rigorous standards. GeoQ takes pride in contributing to the safety, regulatory adherence and operational efficacy of infrastructure across the nation, fostering trust and reliability in every project we undertake.

Supporting Olympic Dam tailings management

GeoQ has been involved with the leak detection during construction of both the EP6 and EP7 evaporation dams at BHP’s Olympic Dam for Teneo and Exact Contracting.

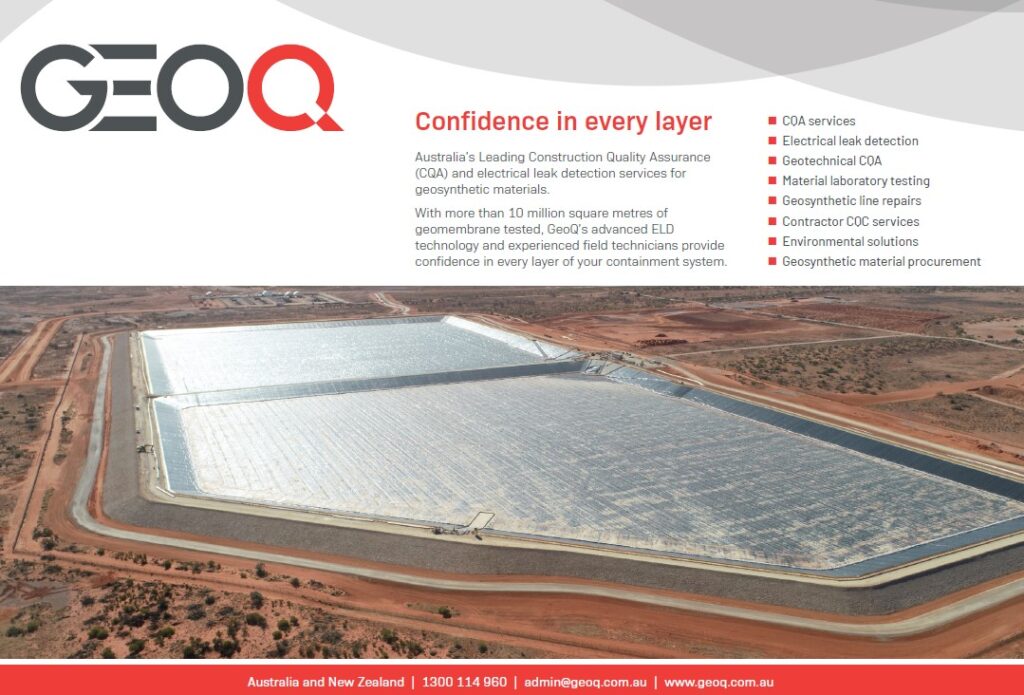

The EP7 evaporation pond at Olympic Dam, covering over 750,000m² of installed lining material required a highly technical, multi-layered geosynthetic lining system to contain tailings from the mine. Given the fast-paced installation schedule, rapid turnaround of ELD reporting was crucial. The extreme environmental conditions of South Australia further added to the complexity of the project.

GeoQ deployed a team of five technicians working on a continuous 2:1 roster to facilitate ELD behind the lining contractor. Its team meticulously identified leaks and within the geosynthetic system, ensuring repairs were completed before the primary liner was applied.

The project required working across vast areas equivalent to the surface area of 600 Olympic-sized swimming pools, all while maintaining stringent compliance with environmental and industry standards.

The civil contractor was able to close out designated sections in an expedited manner, ensuring seamless progress in the installation of the primary liner. GeoQ’s efficiency and expertise allowed for the timely completion of ELD, supporting critical infrastructure development for the Olympic Dam mine.

As the largest leak detection company in Australia, GeoQ’s extensive experience from previous successful projects, including EP6, ensured seamless execution on EP7. Its work plays a vital role in protecting groundwater from contamination by heavy metal tailings, reinforcing the mine’s environmental compliance and contributing significantly to the South Australian economy. Through precision and diligence, its team once again demonstrated its capability in delivering industry-leading quality assurance in geosynthetic lining projects.

Beyond CQA, GeoQ offers expertise in material laboratory testing, ensuring all construction materials satisfy the required specifications, and provides contractor CQC services to support effective project management and compliance.

Partnering with GeoQ means securing a commitment to accuracy, dependability and exceptional environmental management.