Raising the standard: hygienic ice dispensing solutions for mining in 2025

In 2025, mining operations across Australia and beyond are redefining what it means to run a safe, hygienic, and efficient worksite. Every detail matters, especially in the harsh, high-temperature environments where miners rely on clean, accessible ice to stay cool and hydrated. The ice room has become more than a convenience; it’s an essential part of workplace health and safety. That’s why modern dispensing technology, such as touch-free and push-button ice dispensers, are now seen as a key upgrade for mine sites.

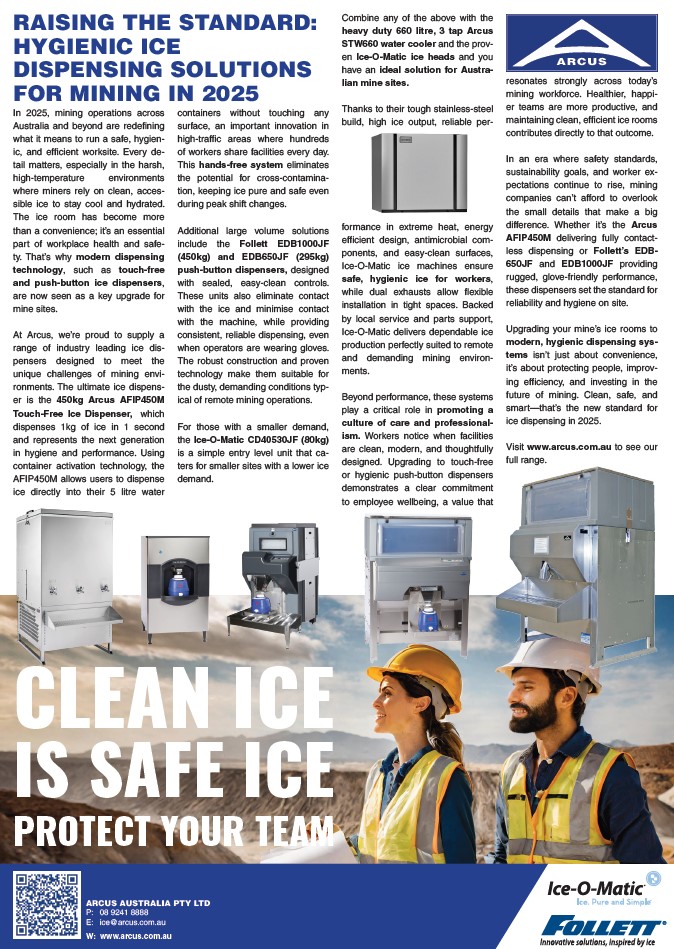

At Arcus, we’re proud to supply a range of industry leading ice dispensers designed to meet the unique challenges of mining environments. The ultimate ice dispenser is the 450kg Arcus AFIP450M Touch-Free Ice Dispenser, which dispenses 1kg of ice in 1 second and represents the next generation in hygiene and performance. Using container activation technology, the AFIP450M allows users to dispense ice directly into their 5 litre water containers without touching any surface, an important innovation in high-traffic areas where hundreds of workers share facilities every day. This hands-free system eliminates the potential for cross-contamination, keeping ice pure and safe even during peak shift changes.

Additional large volume solutions include the Follett EDB1000JF (450kg) and EDB650JF (295kg) push-button dispensers, designed with sealed, easy-clean controls. These units also eliminate contact with the ice and minimise contact with the machine, while providing consistent, reliable dispensing, even when operators are wearing gloves. The robust construction and proven technology make them suitable for the dusty, demanding conditions typical of remote mining operations.

For those with a smaller demand, the Ice-O-Matic CD40530JF (80kg) is a simple entry level unit that caters for smaller sites with a lower ice demand.

Combine any of the above with the heavy duty 660 litre, 3 tap Arcus STW660 water cooler and the proven Ice-O-Matic ice heads and you have an ideal solution for Australian mine sites. Thanks to their tough stainless-steel build, high ice output, reliable performance in extreme heat, energy efficient design, antimicrobial components, and easy-clean surfaces, Ice-O-Matic ice machines ensure safe, hygienic ice for workers, while dual exhausts allow flexible installation in tight spaces. Backed by local service and parts support, Ice-O-Matic delivers dependable ice production perfectly suited to remote and demanding mining environments.

Beyond performance, these systems play a critical role in promoting a culture of care and professionalism. Workers notice when facilities are clean, modern, and thoughtfully designed. Upgrading to touch-free or hygienic push-button dispensers demonstrates a clear commitment to employee wellbeing, a value that resonates strongly across today’s mining workforce. Healthier, happier teams are more productive, and maintaining clean, efficient ice rooms contributes directly to that outcome.

In an era where safety standards, sustainability goals, and worker expectations continue to rise, mining companies can’t afford to overlook the small details that make a big difference. Whether it’s the Arcus AFIP450M delivering fully contactless dispensing or Follett’s EDB650JF and EDB1000JF providing rugged, glove-friendly performance, these dispensers set the standard for reliability and hygiene on site. Upgrading your mine’s ice rooms to modern, hygienic dispensing systems isn’t just about convenience, it’s about protecting people, improving efficiency, and investing in the future of mining. Clean, safe, and smart—that’s the new standard for ice dispensing in 2025.

Visit www.arcus.com.au to see our full range.