When you’re running a mining camp or major mineral processing operation, reliable and durable equipment are what keep production moving and need solar street lights. With multiple projects happening simultaneously in different areas of a site, particularly in applications prone to low visibility and high wind, dusty conditions, the ideal lighting solutions are critical.

Mining companies want products that perform when it counts and rely on suppliers to understand what problems that may encounter ahead of time. This comes down to products that are designed to meet specific site needs, but can also be adapted to constantly changing onsite activities.

In the absence of electrical connectivity in remote sections of a mine, combined with a shift toward more sustainable lighting technology, products must be able to rely on alternative forms of power derived from renewable sources.

Australian company MOMA Solar is shaking up lighting solutions in the mining industry with its range of high quality, environmentally conscious products.

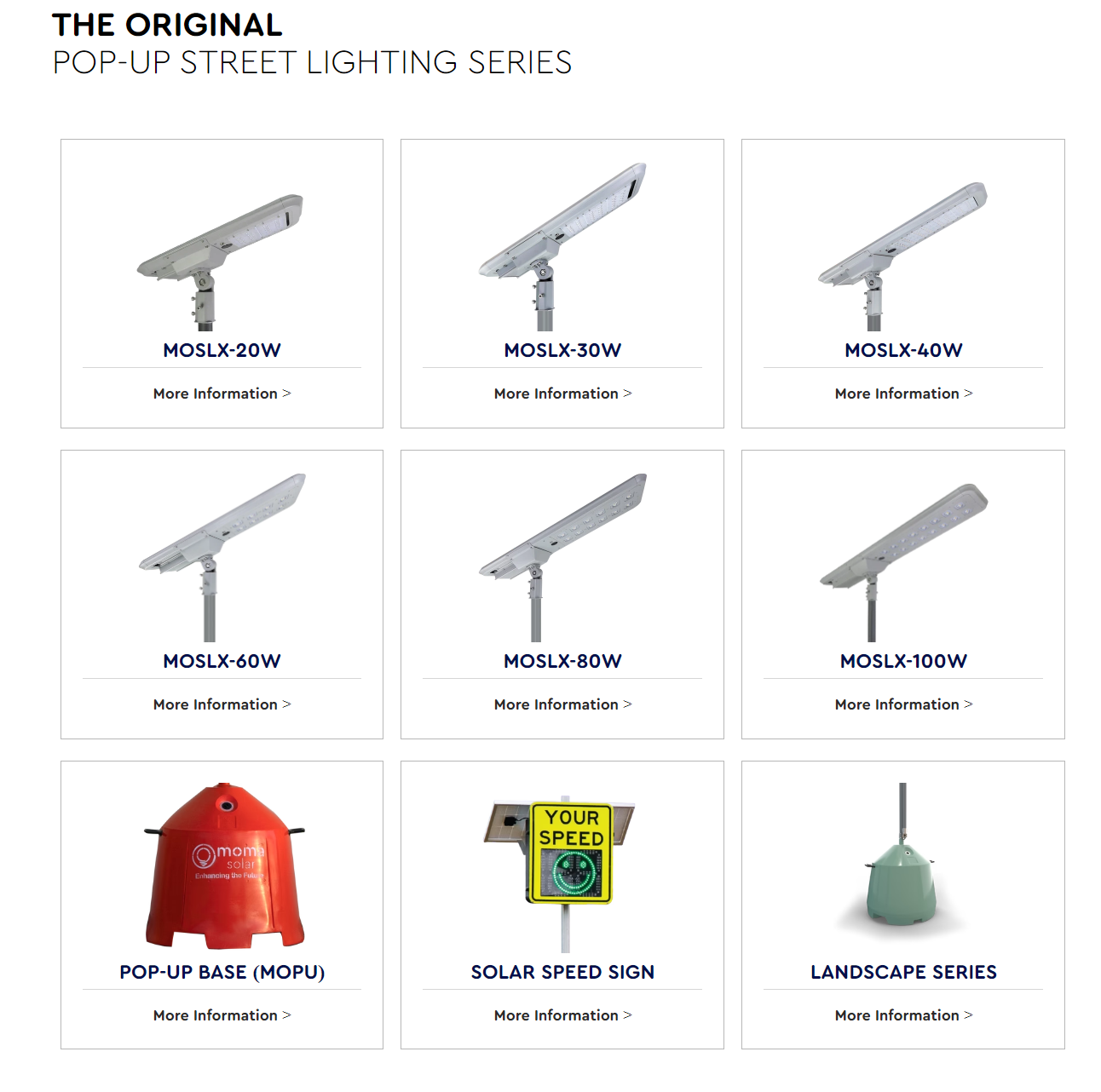

The company supplies a range of solar products including both temporary lighting and permanent solutions, from lighting pathways, buildings and storage containers to radar speed signs, vandal proof bollards and security cameras. Once installed, their solar LED systems require minimal maintenance and also help companies lower their operational costs.

According to Michael Jarvis, Director of MOMA Solar, the company has worked extensively alongside Australia’s most recognised mining companies to design products that meet the unique requirements faced by mines of all sizes.

“As miners look for solutions that help them achieve their robust sustainability agendas, it’s only natural they adopt renewable technology,” said Mr Jarvis.

“We’re committed to creating positive environmental change by developing sustainable solutions at an affordable price, and our commercial and industrial solar LED lighting solutions reflect this.”

MOMA’s water and sand filled bases have proven ideal for mining camps as they offer a no-dig solution to temporary lighting, are easy to move in fluctuating weather conditions, and can be reused for future camp sites.

The company’s bases are category A and B wind region certified, and the solar panels are easy to clean with soap and water for high dust areas. MOMA’s lighting products have been designed to operate with continued autonomous battery maintenance in low light areas, reducing the chance of battery depletion during low light or dim weather conditions.

Weighting just 37kg when empty and approximately 637kg when filled, it is not only a great zero emissions alternative, but can also help reduce onsite risks often associated with lighting and lighting towers.

The module is fitted with convenient lift handles and does not require any additional equipment to assemble. It is an ideal alternative to concrete or diesel generators which can weigh up to 1 tonne, which pose a risk to onsite personnel during the unloading, assembling and dismantling process.

The Pop-Up Base removes this risk entirely to create a safer working environment. The lightweight nature of the base provides easy stacking for transportation and storage, which promotes ongoing use and reduced waste. The base can be easily moved if lighting requirements change over the course of a project without the need to re-hire or transport specialised equipment to facilitate the move.

It’s also compatible with the patented Swivel Joint pole created by Swivelpole. Available in either 4m or 6m, the Swivel Joint pole can be easily lowered or raised as required, eliminating the need to assemble or access mounted lighting or equipment at heights.

“Working at heights is often one of the most common risks associated with mine sites,” said Mr Jarvis.

“By removing risk with products like the patented Swivelpole, we are able to offer clients peace of mind when it comes to ongoing maintenance in high dust areas. No specialised equipment is needed to access the solar light head, which provides easy maintenance, and seamless removal and replacement if required.

“Additionally, onsite electricians have a high risk of electrical shocks or short circuits with low voltage equipment often in use. To combat any potential risk, our solar light head is extra low voltage, which allows the electricians to conduct maintenance checks or install replacement parts, without compromising their safety.”

Aside from onsite personnel, there are also environmental risks to be considered when erecting lighting towers. In the case of diesel-powered towers, common risks include emissions, spills, ground leaching and noise pollution.

Although more applicable to onsite personnel, the installation of concrete bases poses an environmental risk due to the ground surface impact and subsequent removal of the unit. The area around a concrete installation experiences heavy disturbance from the equipment required to keep personnel safe. Despite these necessary safety measures, the environmental risk relates to the equipment used, which is generally diesel powered.

“Using a solar light head and water fillable base mitigates these risks,” said Mr Jarvis.

“Our bases are made of durable MDPE that do not leach any harmful chemicals into the water over the duration of its use, making it safe to empty onsite as required.

“As the light head is battery powered, you don’t get any noise pollution or any low ground vibration from the use of engines. The unit can also be assembled by hand, removing the risk of heavy ground impact during installation and removal from site.”

Another obvious risk relates to low light conditions or unreliable lighting. Insufficient lighting for a specific application can often lead to hazards associated with poor visibility. This can include potential trip hazards or site personnel running into obstacles that are not clearly visible, through to more significant risks such as poor visibility when operating equipment. A fit-for-purpose lighting tower removes these risks and provides a safer working environment for all personnel actively performing duties or during their downtime.

While poor lighting can be associated with low lighting, bright light and glare must also be considered. MOMA Solar offers lighting engineering services at no additional cost for this very reason, ensuring fit-for-purpose lighting is provided in alignment with all Australian Lighting Standards and any site lux requirements.

The easy assembly and disassembly of the Solar Pop-Up Module allows mine managers to secure sufficient lighting quickly wherever it’s needed. Should either a higher or lower lux level be required, the pole can be easily lowered, and a new light head attached to suit site applications. The same base and pole can also be repeatedly used to reduce waste, extending the life of the product.

Allowing not only lighting to be mounted, but also additional onsite equipment that would otherwise be mounted using a concrete or a diesel-powered base, mine sites will benefit from the ability to mount air monitoring equipment, communications modules, road monitoring equipment and instrumentation, onto a single unit.

There are also other portable lighting solutions provided by Moma Solar

For more information, visit https://www.momasolar.com.au/