Multi-float® hose and cable floats redefine liquid management

As Australia’s leading liquid control specialists, Coerco’s Multi-Float® hose and cable floats reflect a commitment to product innovation and quality engineering. For almost 20 years, these flotation solutions ensure pipeline, hose, and cable stability in the most challenging industrial environments.

From mines and industrial infrastructure to dewatering operations and water treatment facilities, Coerco’s purpose-built Multi-Float® products provide reliable, durable, and adaptable flotation systems for projects in Australia and abroad.

Originally developed in 2008 for a Cooljarloo slurry pipeline project, these versatile, durable and adaptable floats have gained popularity across Australian mining, municipal, and renewable energy projects. They have since been successfully deployed in large-scale projects around the world.

Manufactured in Australia, thoroughly tested, and compliant with international standards, the Multi-Float® hose and cable floats are designed for multiple applications, from dewatering and dredging to slurry pipelines and heavy-duty floating pump systems, in the harshest industrial environments.

Speaking with Coerco Resources Sales Manager, Daniel Rignall, it’s clear why Coerco’s flotation solutions are a cut above the rest.

“Our purpose-built floats are engineered with stability, operational efficiency, and safety in mind,” said Rignall.

“Each product is manufactured from chemically resistant polyethylene that is capable of withstanding corrosive environments, extreme UV exposure, and heavy-duty industrial use. With float sizes ranging from 75mm to 1200mm, and the option of foam-filled redundancy, flotation integrity will be maintained, even in the unlikely event of a puncture.”

Rignall added, “Our modular bush kits also allow for precise reductions to accommodate varying pipe and cable diameters, ensuring a secure grip that prevents movement or displacement under pressure. Not only do Coerco’s floats secure and protect cables, hoses and pipes from damage in exposed water bodies, but reduce maintenance costs and extend equipment life.”

Proven flotation solutions

Coerco’s involvement in large-scale projects on a global level is a testament to its world-class solutions, engineering capabilities, and technical expertise.

In 2008, Tiwest (now Tronox) upgraded its Cooljarloo Mineral Sand Mine to improve pumping efficiencies for its dredging operation. Situated approximately 170km north of Perth, Cooljarloo is a key site for extracting heavy minerals from ancient shoreline deposits in the Lancelin to Gingin region. The project saw Coerco collaborate closely with the mine’s team to develop and deliver a tailored flotation solution in just three months. This included 156 pipe floats (450mm) for slurry pipelines, several 90mm floats for electric cables, and 315mm floats for other site-specific needs.

Today, the pipe float system supports Tronox in producing over 770,000 metric tons of heavy mineral concentrate annually. Using floating dredges and a concentrator, the mine efficiently processes ore, while maintaining consistent feedstock to the Chandala processing plant for further refinement.

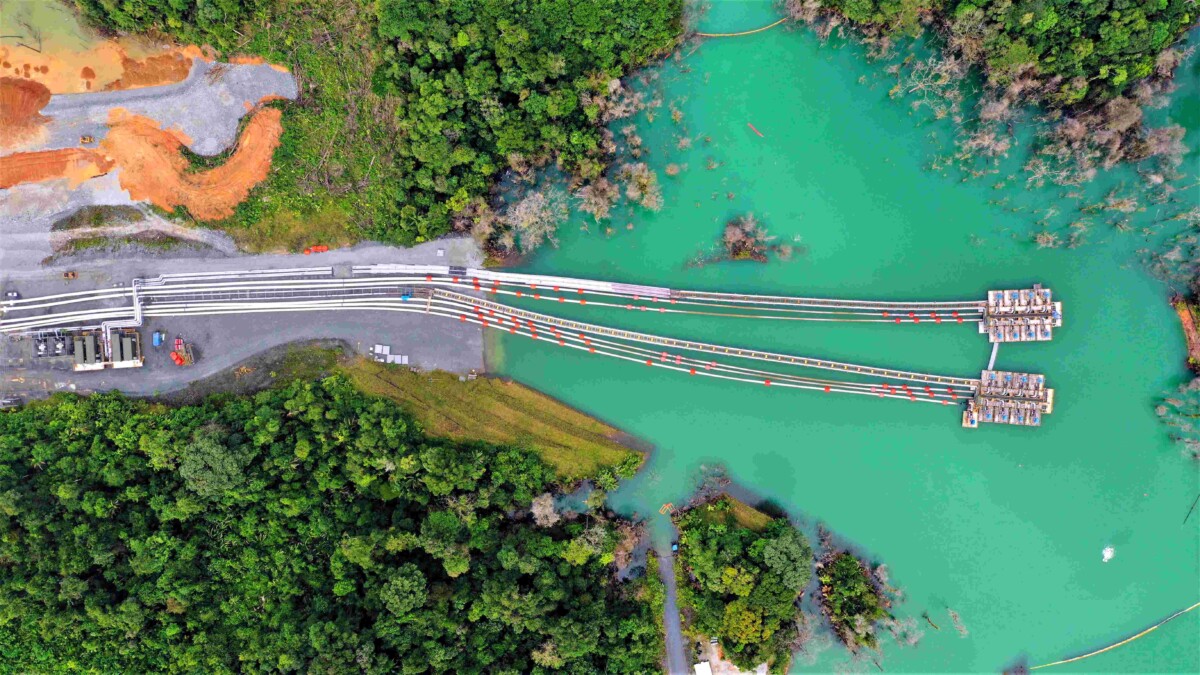

Another example is Panama’s First Quantum Minerals, where Coerco addressed the challenges of expanding a large dewatering system into areas with deeper water deposits. At the First Quantum Minerals copper mine, which is made up of multiple sites spanning 13,600 hectares, rising water levels posed a significant challenge. However, Coerco’s innovative approach delivered a rapid solution that could be assembled in-situ to manage the influx of water efficiently.

A specialised dewatering system was designed to support critical mineral processing operations at the site, which involved the supply of a large number of Multi-Float® pipe floats. These were seamlessly integrated into the dewatering infrastructure for robust and reliable performance.

“One Aussie project really tested all of the team here at Coerco,” said Rignall.

“The Kidston Hydro Project—a landmark renewable energy project in Far-North Queensland, and the first pumped storage hydro project in Australia in over 40 years—challenged us on all technical design, fabrication, and logistical fronts. We had to deal with a remote location, tough terrain, accessibility and serviceability issues, and incredibly complex engineering requirements.”

Coerco were tasked with designing a dewatering solution that could pump 30 gigalitres of water from an abandoned gold mine, one that could manoeuvre with fluctuating water levels at a vertical depth of 180 metres.

Working with engineering consultants, pump manufacturers, and lead contractors, a heavy-duty yet stable modular Multi-Float® pontoon structure was custom-built after an in-depth 12-month design and review process. The team also engineered a winch system capable of safely launching the pontoon into the dam, while a helicopter was used to lower personnel down the pit embankment to install the manifolds, pumps, and motors onto the pontoon.

Optimising pipeline buoyancy

No matter the technical requirements, liquid control application, geographical location or ruggedness of the terrain, Coerco’s expertise extends beyond simply supplying floats. It serves as a technical partner and problem solver at every stage of the product development process.

This niche expertise and deep understanding of the physics of fluid control and complex liquid management is evident in Coerco’s approach to projects utilising its Multi-Float® products. The team help clients calculate and optimise buoyancy requirements for various applications by providing the methodology and engineering capabilities needed to determine precise buoyancy solutions for industrial pipelines, hoses, and cables.

A common cause of failure in liquid management projects is oversight of not only strict site requirements and design parameters, but also principles such as buoyancy. Coerco’s expertise in buoyancy engineering has been instrumental in major global infrastructure projects, notably Sydney Water’s Picton Water Resource Recovery Facility and the Grande Côte Mineral Sands Operation, as well as offshore mine dewatering systems such as Genesis Minerals’ Tower Hill Pit project.

“In the Sydney Water project, we were contracted by Xylem to design, engineer and manufacture a fit-for-purpose pump, pontoon system, and access gangway at the Picton wastewater facility,” explained Rignall.

“This involved producing detailed drawings, FDA analysis, and buoyancy calculations that were critical in manufacturing a modular floating structure capable of withstanding high wind loads and other harsh environmental conditions.”

The Coerco team also conducted site assessments of the lake topography, soil conditions, water density, submergence and fluctuations in water levels, and pump dimensions. The solution not only saved Sydney Water time and money, but the mix of design, materials, and engineering methodology contributed to increased safety and compliance with Australian standards.

Tailored buoyancy assessments

Coerco applies a precise methodology to determine the ideal number, type, and spacing of floats required for optimal buoyancy. With a range of Multi-Float® hose floats, the company provides flexible solutions tailored to specific project needs. By factoring in variables such as pipe size, fluid density, environmental conditions, and operational loads, we ensure pipelines and cables remain securely suspended without excess strain or instability.

In straightforward applications, Coerco’s pipe float calculator enables clients to input project specifications and obtain an immediate flotation assessment. However, for more complex projects involving slurry lines, variable SGs (specific gravities), or mixed-use cable and pipe applications, the team leverages advanced engineering calculations and in-depth consultation to design the most effective flotation strategy.

Practical solutions, long-term results

No matter the location, Coerco’s engineered solutions cater for projects of all scopes, sizes and complexities. Coerco applies in-depth knowledge of liquid management, to deliver practical and cost-effective solutions that help asset owners avoid unnecessary downtime and cost blowouts.

As a family-owned and operated company with over 450 years of combined experience and more than 300 products, the company pushes the boundaries to deliver top-tier liquid management outcomes. The team thrives on tailoring solutions to meet specific sites and client needs—from design and engineering to manufacturing, delivery and commissioning.

By choosing Coerco, clients benefit from an end-to-end service solution, spanning initial flotation analysis and design to manufacturing, delivery, and ongoing maintenance and technical support. As industries continue to demand higher precision and reliability in their liquid transport infrastructure, Coerco remains at the forefront, offering world-class flotation solutions that ensure stability, efficiency, and reliable long-term performance.

Connect with Coerco today and discover how our liquid management expertise can benefit your next project.

1800 646 277

info@coerco.com.au

www.coerco.com.au