North Queensland Hardfacing — pioneering wear solutions across Australia’s heavy industries

In the rugged and demanding world of mining and construction, equipment durability is a cornerstone of operational success. Downtime due to equipment failure can lead to significant operational setbacks, driving up costs and delaying projects. North Queensland Hardfacing (NQHF), established in 1996, has risen to the challenge of minimising these disruptions. As a leading supplier of tungsten hardfaced cutting edges and Ground Engaging Tools (GET), NQHF has made a name for itself by offering products that dramatically increase the wear life of equipment, thereby reducing downtime for repairs and maintenance. Serving key regions across Australia, NQHF’s commitment to quality, innovation and customer service has made it a trusted partner in the industry.

A commitment to excellence

Since its inception nearly three decades ago, NQHF has been driven by a singular vision: to provide top-tier wear solutions that meet the unique demands of Australia’s heavy industries. From its headquarters in North Queensland, the company has expanded its reach to service North and Western Queensland, Central Queensland, the Northern Territory, WA, and the Hunter Valley. These regions, home to some of Australia’s most intensive mining and construction activities, rely on NQHF’s products to keep their operations running smoothly.

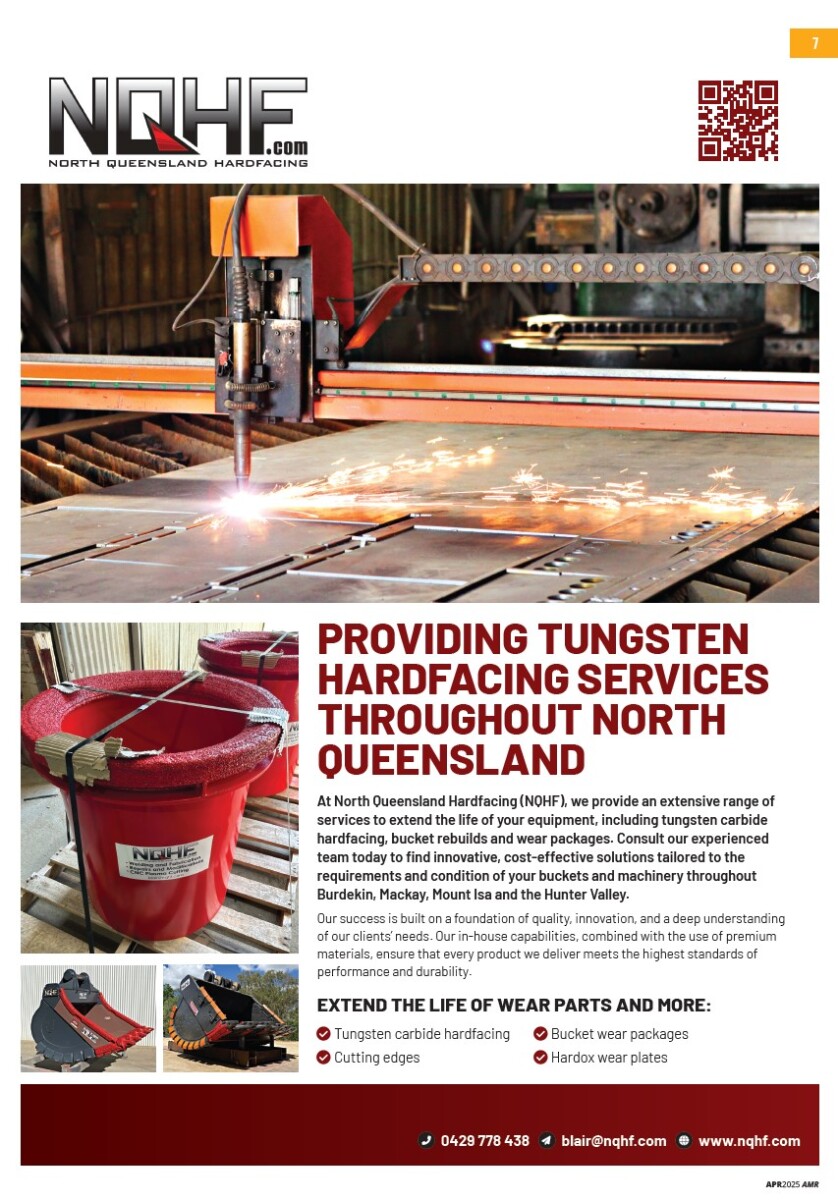

In-house production: a guarantee of quality and efficiency

One of the hallmarks of NQHF’s operations is its comprehensive in-house production capability. The company designs, cuts, drills and hardfaces all its products within its own facilities, ensuring tight control over quality and production timelines. This in-house approach allows NQHF to offer quick turnaround times, a crucial advantage in an industry where delays can be costly.

This control over the production process means that NQHF can customise its products to meet the precise requirements of its clients. Whether it’s a bespoke wear plate or a specialised cutting edge, NQHF has the flexibility to deliver solutions that are tailored to the specific challenges faced by its customers. This customisation is particularly valuable in sectors like mining, where equipment is often subjected to extreme conditions that require specialised solutions.

Hardox wear plates: the backbone of durable equipment

Central to NQHF’s product range is its selection of Hardox wear plates, renowned for their exceptional durability and wear resistance. NQHF stocks Hardox wear plates in sizes ranging from 3mm to 60mm, providing a wide array of options to suit various applications. These wear plates are particularly prized in the mining and construction industries, where equipment is constantly exposed to abrasive and heavy-duty conditions.

By incorporating Hardox wear plates into their machinery, businesses can significantly extend the service life of their equipment. This not only reduces the frequency of repairs and replacements but also improves overall operational efficiency. NQHF’s ability to design and manufacture these wear plates in-house, combined with its expertise in CNC machining of countersunk holes, ensures that every product meets the highest standards of precision and performance.

Tungsten carbide hardfacing: enhanced durability for critical components

Another cornerstone of NQHF’s offerings is its expertise in tungsten carbide hardfacing. Tungsten carbide is one of the hardest materials available, making it ideal for applications where wear and abrasion are major concerns. NQHF imports premium quality tungsten carbide and applies it using specialised techniques that ensure a durable, long-lasting finish.

This process is particularly valuable for Ground Engaging Tools (GET) and cutting edges, which are often the first points of contact with abrasive materials. By adding a layer of tungsten carbide, NQHF significantly enhances the durability of these components, reducing wear and extending their operational life. This not only saves clients money on replacements but also improves the overall efficiency and productivity of their equipment.

Custom wear plates: engineered for extreme conditions

NQHF has also developed a strong reputation for its custom-designed wear plates. These plates are engineered to withstand the most challenging conditions, providing an extra layer of protection for machinery and equipment.

The ability to design and produce custom wear plates is particularly valuable in industries like mining, where equipment is often subjected to extreme stress. NQHF’s wear plates help to mitigate the effects of wear and tear, extending the lifespan of the equipment and reducing the need for costly repairs and replacements.

Overlay plate stockists and chokky blocks: versatile solutions for wear protection

NQHF’s commitment to providing comprehensive wear solutions is further evidenced by its role as a stockist of overlay plates and chokky blocks. These products are essential for lining chutes, hoppers, and other equipment components that are subject to heavy wear. NQHF’s overlay plates and chokky blocks are designed to offer superior wear protection, helping to maintain the integrity of equipment and reduce maintenance costs.

These solutions are particularly valuable in industries where equipment is exposed to continuous abrasion and impact. By providing high-quality overlay plates and chokky blocks, NQHF ensures that its clients have access to the best possible protection for their machinery, further enhancing the longevity and performance of their equipment.

Comprehensive services: bucket rebuilds, mobile abrasive blasting and painting

NQHF’s commitment to its clients extends beyond the production of high-quality wear parts. The company also offers a range of services designed to support the maintenance and longevity of heavy equipment. One such service is bucket rebuilds, where NQHF restores worn or damaged buckets to their original condition. This service not only saves clients the cost of purchasing new buckets but also extends the life of their existing equipment.

In addition to bucket rebuilds, NQHF provides mobile abrasive blasting and painting services. These services are essential for maintaining the integrity and appearance of equipment. By offering these services, NQHF ensures that its clients have access to comprehensive support for all their equipment maintenance needs.

Innovation and quality: the NQHF difference

As the industries NQHF serves continue to evolve, the company remains committed to staying at the forefront of wear solutions. By investing in new technologies and continually refining its processes, NQHF is well-positioned to meet the challenges of the future, providing its clients with the tools they need to succeed.

For nearly three decades, North Queensland Hardfacing has been a trusted partner for mining and construction companies across Australia. With its comprehensive range of products and services, all backed by a commitment to quality and innovation, NQHF is more than just a supplier — it is a vital contributor to the success and longevity of its clients’ operations.