The Goonyella paradox

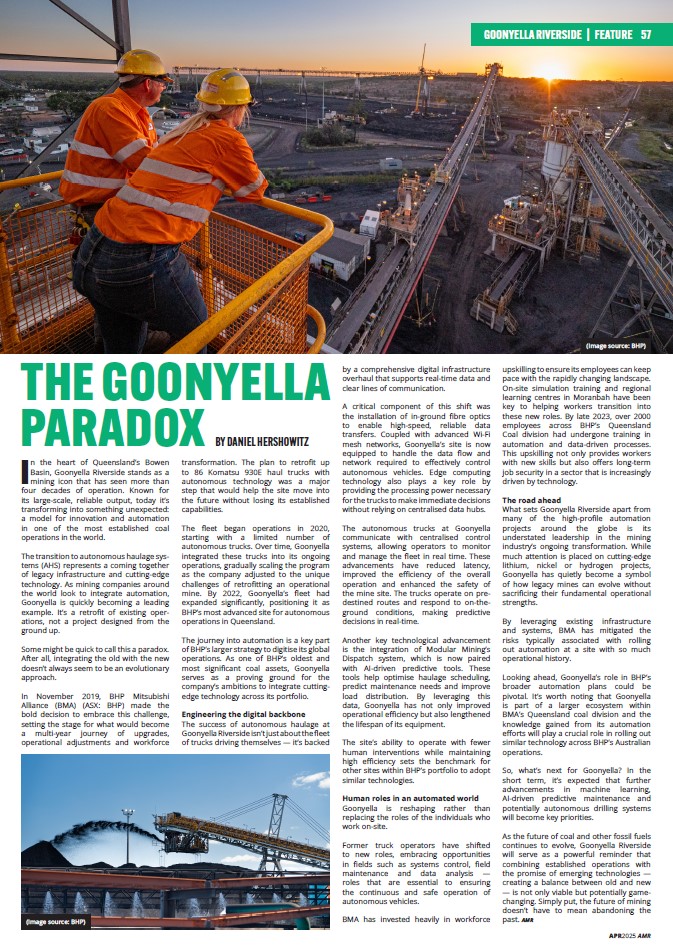

In the heart of Queensland’s Bowen Basin, Goonyella Riverside stands as a mining icon that has seen more than four decades of operation. Known for its large-scale, reliable output, today it’s transforming into something unexpected: a model for innovation and automation in one of the most established coal operations in the world.

The transition to autonomous haulage systems (AHS) represents a coming together of legacy infrastructure and cutting-edge technology. As mining companies around the world look to integrate automation, Goonyella is quickly becoming a leading example. It’s a retrofit of existing operations, not a project designed from the ground up.

Some might be quick to call this a paradox. After all, integrating the old with the new doesn’t always seem to be an evolutionary approach.

In November 2019, BHP Mitsubishi Alliance (BMA) (ASX: BHP) made the bold decision to embrace this challenge, setting the stage for what would become a multi-year journey of upgrades, operational adjustments and workforce transformation. The plan to retrofit up to 86 Komatsu 930E haul trucks with autonomous technology was a major step that would help the site move into the future without losing its established capabilities.

The fleet began operations in 2020, starting with a limited number of autonomous trucks. Over time, Goonyella integrated these trucks into its ongoing operations, gradually scaling the program as the company adjusted to the unique challenges of retrofitting an operational mine. By 2022, Goonyella’s fleet had expanded significantly, positioning it as BHP’s most advanced site for autonomous operations in Queensland.

The journey into automation is a key part of BHP’s larger strategy to digitise its global operations. As one of BHP’s oldest and most significant coal assets, Goonyella serves as a proving ground for the company’s ambitions to integrate cutting-edge technology across its portfolio.

Engineering the digital backbone

The success of autonomous haulage at Goonyella Riverside isn’t just about the fleet of trucks driving themselves — it’s backed by a comprehensive digital infrastructure overhaul that supports real-time data and clear lines of communication.

A critical component of this shift was the installation of in-ground fibre optics to enable high-speed, reliable data transfers. Coupled with advanced Wi-Fi mesh networks, Goonyella’s site is now equipped to handle the data flow and network required to effectively control autonomous vehicles. Edge computing technology also plays a key role by providing the processing power necessary for the trucks to make immediate decisions without relying on centralised data hubs.

The autonomous trucks at Goonyella communicate with centralised control systems, allowing operators to monitor and manage the fleet in real time. These advancements have reduced latency, improved the efficiency of the overall operation and enhanced the safety of the mine site. The trucks operate on pre-destined routes and respond to on-the-ground conditions, making predictive decisions in real-time.

Another key technological advancement is the integration of Modular Mining’s Dispatch system, which is now paired with AI-driven predictive tools. These tools help optimise haulage scheduling, predict maintenance needs and improve load distribution. By leveraging this data, Goonyella has not only improved operational efficiency but also lengthened the lifespan of its equipment.

The site’s ability to operate with fewer human interventions while maintaining high efficiency sets the benchmark for other sites within BHP’s portfolio to adopt similar technologies.

Human roles in an automated world

Goonyella is reshaping rather than replacing the roles of the individuals who work on-site.

Former truck operators have shifted to new roles, embracing opportunities in fields such as systems control, field maintenance and data analysis — roles that are essential to ensuring the continuous and safe operation of autonomous vehicles.

BMA has invested heavily in workforce upskilling to ensure its employees can keep pace with the rapidly changing landscape. On-site simulation training and regional learning centres in Moranbah have been key to helping workers transition into these new roles. By late 2023, over 2000 employees across BHP’s Queensland Coal division had undergone training in automation and data-driven processes. This upskilling not only provides workers with new skills but also offers long-term job security in a sector that is increasingly driven by technology.

The road ahead

What sets Goonyella Riverside apart from many of the high-profile automation projects around the globe is its understated leadership in the mining industry’s ongoing transformation. While much attention is placed on cutting-edge lithium, nickel or hydrogen projects, Goonyella has quietly become a symbol of how legacy mines can evolve without sacrificing their fundamental operational strengths.

By leveraging existing infrastructure and systems, BMA has mitigated the risks typically associated with rolling out automation at a site with so much operational history.

Looking ahead, Goonyella’s role in BHP’s broader automation plans could be pivotal. It’s worth noting that Goonyella is part of a larger ecosystem within BMA’s Queensland coal division and the knowledge gained from its automation efforts will play a crucial role in rolling out similar technology across BHP’s Australian operations.

So, what’s next for Goonyella? In the short term, it’s expected that further advancements in machine learning, AI-driven predictive maintenance and potentially autonomous drilling systems will become key priorities.

As the future of coal and other fossil fuels continues to evolve, Goonyella Riverside will serve as a powerful reminder that combining established operations with the promise of emerging technologies — creating a balance between old and new — is not only viable but potentially game-changing. Simply put, the future of mining doesn’t have to mean abandoning the past.