Engineering extraction

Boosting efficiency in mineral processing

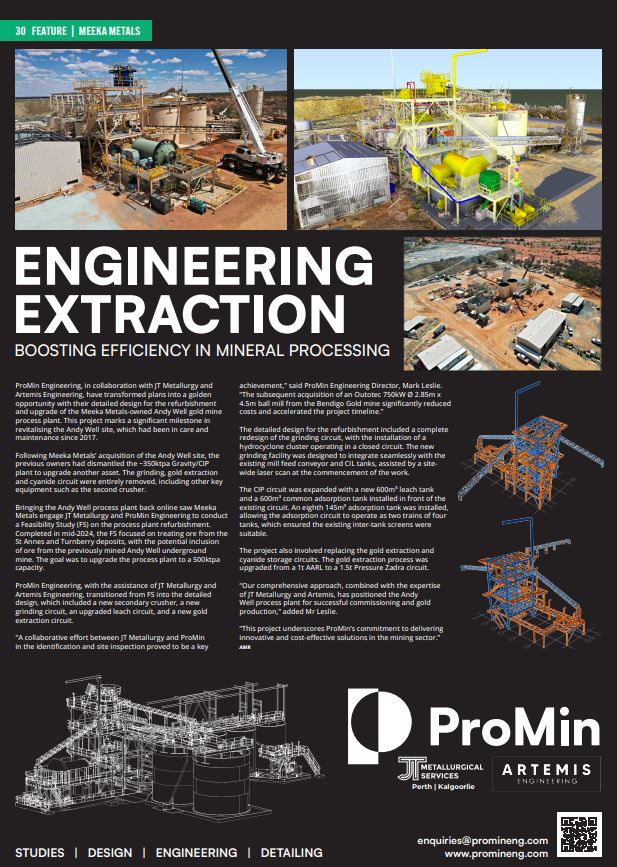

ProMin Engineering, in collaboration with JT Metallurgy and Artemis Engineering, have transformed plans into a golden opportunity with their detailed design for the refurbishment and upgrade of the Meeka Metals-owned Andy Well gold mine process plant. This project marks a significant milestone in revitalising the Andy Well site, which had been in care and maintenance since 2017.

Following Meeka Metals’ acquisition of the Andy Well site, the previous owners had dismantled the ~350ktpa Gravity/CIP plant to upgrade another asset. The grinding, gold extraction and cyanide circuit were entirely removed, including other key equipment such as the second crusher.

Bringing the Andy Well process plant back online saw Meeka Metals engage JT Metallurgy and ProMin Engineering to conduct a Feasibility Study (FS) on the process plant refurbishment. Completed in mid-2024, the FS focused on treating ore from the St Annes and Turnberry deposits, with the potential inclusion of ore from the previously mined Andy Well underground mine. The goal was to upgrade the process plant to a 500ktpa capacity.

ProMin Engineering, with the assistance of JT Metallurgy and Artemis Engineering, transitioned from FS into the detailed design, which included a new secondary crusher, a new grinding circuit, an upgraded leach circuit, and a new gold extraction circuit.

A collaborative effort between JT and ProMin in the identification and site inspection proved to be a key achievement,” said ProMin Engineering Director, Mark Leslie.

“The subsequent acquisition of an Outotec 750kW Ø 2.85m x 4.5m ball mill from the Bendigo Gold mine significantly reduced costs and accelerated the project timeline.”

The detailed design for the refurbishment included a complete redesign of the grinding circuit, with the installation of a hydrocyclone cluster operating in a closed circuit. The new grinding facility was designed to integrate seamlessly with the existing mill feed conveyor and CIL tanks, assisted by a site-wide laser scan at the commencement of the work.

The CIP circuit was expanded with a new 600m³ leach tank and a 600m³ common adsorption tank installed in front of the existing circuit. An eighth 145m³ adsorption tank was installed, allowing the adsorption circuit to operate as two trains of four tanks, which ensured the existing inter-tank screens were suitable.

The project also involved replacing the gold extraction and cyanide storage circuits. The gold extraction process was upgraded from a 1t AARL to a 1.5t Pressure Zadra circuit.

“Our comprehensive approach, combined with the expertise of JT and Artemis, has positioned the Andy Well process plant for successful commissioning and gold production,” added Mr Leslie.

“This project underscores ProMin’s commitment to delivering innovative and cost-effective solutions in the mining sector.”