Right people. Right gear. Smart solutions.

Iron Mine Contracting (IMC) was established to provide mining and civil partnering opportunities to the Australian market.

Since 2013, IMC have delivered projects to Tier 1 mining companies including Rio Tinto, Northern Star Resources, Fortescue, Liontown Resources, Vault Resources, Gold Fields Limited, Roy Hill, Newcrest Mining and Woodside Petroleum.

With extensive experience working for clients in remote areas and a wealth of knowledge gained from a diverse multidisciplinary team, IMC understands the specific challenges that constructing and delivering for its clients presents.

The company’s project delivery teams are highly experienced in delivering projects across Australia. This is backed by a collaborative contracting style that builds strong relationships to ensure projects are completed on budget, with minimal impacts on stakeholders and the surrounding environment.

Headquartered in Osborne Park, IMC operates a fully in-house plant and maintenance team, with an advanced workshop in Bayswater. A new two-hectare workshop site in Muchea is currently in phase one of construction with an office and initial 8-bay workshop due for completion in early 2026. This facility will enable IMC to further expand its vehicle and component remanufacturing capacity in support of maintaining its cost-effective and highly available fleet.

Beyond the pit

IMC offers a diverse range of multidisciplinary services and an integrated approach to provide scalable, schedule-of-rates solutions that align with clients’ specific needs.

In the civil space, IMC’s capability ranges from bulk earthworks and the construction of tailings storage facilities, to site rehabilitation, development of conveyor formations, bulk earthworks and the construction and maintenance of haul roads and sealed pavements.

On the mining side, IMC offers end-to-end solutions that span the entire project lifecycle, from early exploration support through to port loading. The company provides pioneering and early establishment works, drill and blast operations, load and haul activities including Run-of-Mine feed, sizing, and management, along with all ancillary support and technical services, including engineering mine design, plan & schedule.

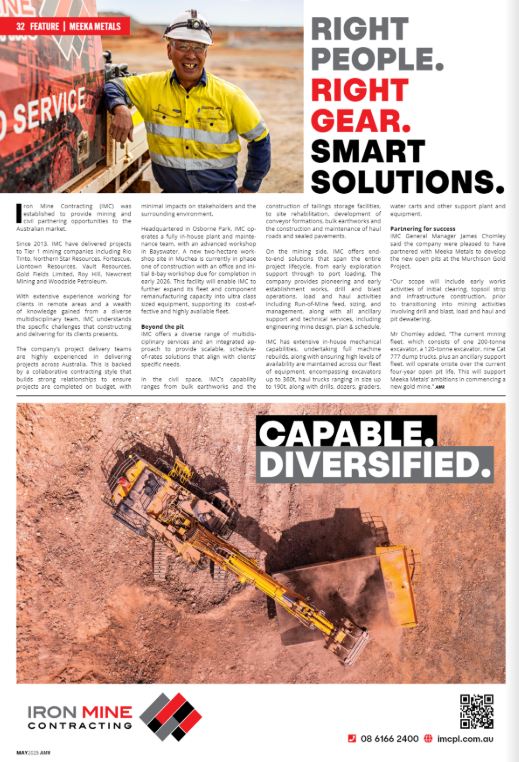

IMC has extensive in-house mechanical capabilities, undertaking full machine rebuilds, along with ensuring high levels of availability are maintained across our fleet of equipment, encompassing excavators up to 360t, haul trucks ranging in size up to 190t, along with drills, dozers, graders, water carts and other support plant and equipment.

Partnering for success

IMC General Manager James Chomley said the company were pleased to have partnered with Meeka Metals to develop the new open pits at the Murchison Gold Project.

“Our scope will include early works activities of initial clearing, topsoil strip and infrastructure construction, prior to transitioning into mining activities involving drill and blast, load and haul and pit dewatering.

Mr Chomley added, “The current mining fleet, which consists of one 200-tonne excavator, a 120-tonne excavator, nine Cat 777 dump trucks, plus an ancillary support fleet, will operate onsite over the current four-year open pit life. This will support Meeka Metals’ ambitions in commencing a new gold mine.”