Strength in Service: JTH’s Edge in Asset Management

Servicing the complex infrastructure requirements in large-scale mining operations is not an easy task. You’re not only dealing with technical engineering specifications and multiple processes, but managing tight deadlines and specific labour needs. That’s where a trusted partner with the right expertise and know-how becomes such an integral piece in the puzzle.

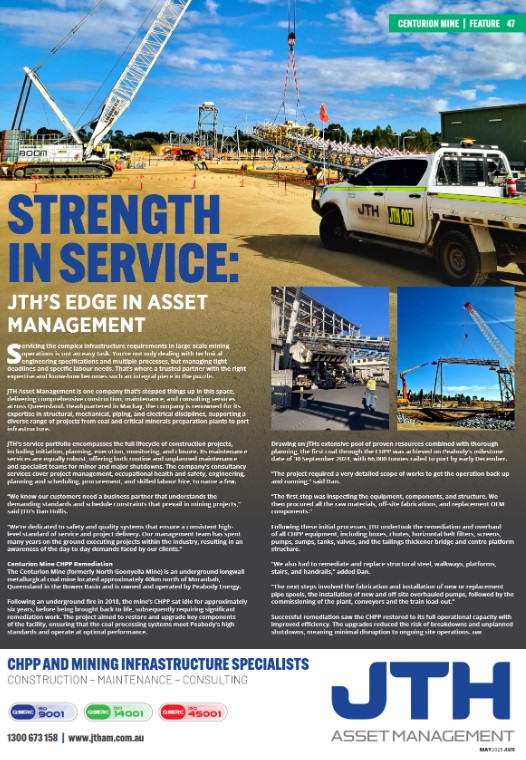

JTH Asset Management is one company that’s stepped things up in this space, delivering comprehensive construction, maintenance, and consulting services across Queensland. Headquartered in Mackay, the company is renowned for its expertise in structural, mechanical, piping, and electrical disciplines, supporting a diverse range of projects from coal and critical minerals preparation plants to port infrastructure.

JTH’s service portfolio encompasses the full lifecycle of construction projects, including initiation, planning, execution, monitoring, and closure. Its maintenance services are equally robust, offering both routine and unplanned maintenance and specialist teams for minor and major shutdowns. The company’s consultancy services cover project management, occupational health and safety, engineering, planning and scheduling, procurement, and skilled labour hire, to name a few.

“We know our customers need a business partner that understands the demanding standards and schedule constraints that prevail in mining projects,” said JTH’s Dan Hollis.

“We’re dedicated to safety and quality systems that ensure a consistent high-level standard of service and project delivery. Our management team has spent many years on the ground executing projects within the industry, resulting in an awareness of the day-to-day demands faced by our clients.”

Centurion Mine CHPP Remediation

The Centurion Mine (formerly North Goonyella Mine) is an underground longwall metallurgical coal mine located approximately 40km north of Moranbah, Queensland in the Bowen Basin and is owned and operated by Peabody Energy.

Following an underground fire in 2018, the mine’s CHPP sat idle for approximately six years, before being brought back to life, subsequently requiring significant remediation work. The project aimed to restore and upgrade key components of the facility, ensuring that the coal processing systems meet Peabody’s high standards and operate at optimal performance.

Drawing on JTHs extensive pool of proven resources combined with thorough planning, the first coal through the CHPP was achieved on Peabody’s milestone date of 30 September 2024, with 66,000 tonnes railed to port by early December.

“The project required a very detailed scope of works to get the operation back up and running,” said Dan.

“The first step was inspecting the equipment, components, and structure. We then procured all the raw materials, off-site fabrications, and replacement OEM components.”

Following these initial processes, JTH undertook the remediation and overhaul of all CHPP equipment, including boxes, chutes, horizontal belt filters, screens, pumps, sumps, tanks, valves, and the tailings thickener bridge and centre platform structure.

“We also had to remediate and replace structural steel, walkways, platforms, stairs, and handrails,” added Dan.

“The next steps involved the fabrication and installation of new or replacement pipe spools, the installation of new and off-site overhauled pumps, followed by the commissioning of the plant, conveyors and the train load-out.”

Successful remediation saw the CHPP restored to its full operational capacity with improved efficiency. The upgrades reduced the risk of breakdowns and unplanned shutdowns, meaning minimal disruption to ongoing site operations.