Titeline Drilling

Leveraging expertise and innovation to transform the underground drilling sector

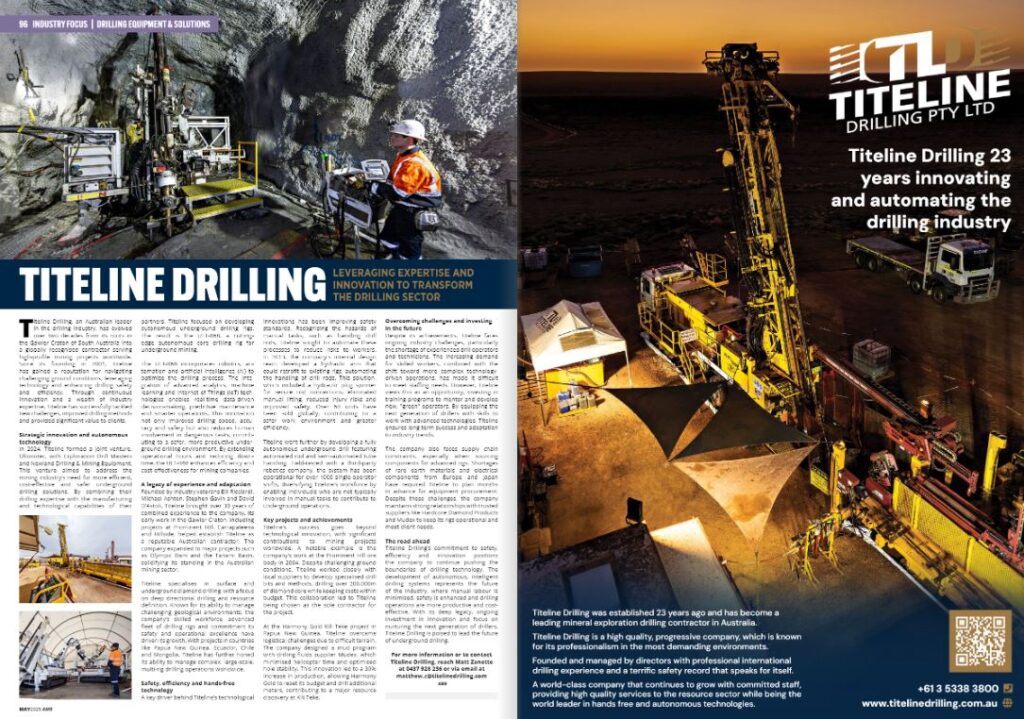

Titeline Drilling, an Australian leader in the drilling industry, has evolved over two decades from its roots in the Gawler Craton of South Australia into a globally recognised contractor serving high-profile mining projects worldwide. Since its founding in 2001, Titeline has gained a reputation for navigating challenging ground conditions, leveraging technology and enhancing drilling safety and efficiency. Through continuous innovation and a wealth of industry expertise, Titeline has successfully tackled new challenges, improved drilling methods and provided significant value to clients.

Strategic innovation and autonomous technology

In 2024, Titeline formed a joint venture, Ultonotec, with Exploration Drill Masters and Newland Drilling & Mining Equipment. This venture aimed to address the mining industry’s need for more efficient, cost-effective and safer underground drilling solutions. By combining their drilling expertise with the manufacturing and technological capabilities of their partners, Titeline focused on developing autonomous underground drilling rigs. The result is the ULT-R68, a cutting-edge autonomous core drilling rig for underground mining.

The ULT-R68 incorporates robotics, automation and artificial intelligence (AI) to optimise the drilling process. The integration of advanced analytics, machine learning and Internet of Things (IoT) technologies enables real-time data-driven decision-making, predictive maintenance and smarter operations. This innovation not only improves drilling speed, accuracy and safety but also reduces human involvement in dangerous tasks, contributing to a safer, more productive underground drilling environment. By extending operational hours and reducing downtime, the ULT-R68 enhances efficiency and cost-effectiveness for mining companies.

A legacy of experience and adaptation

Founded by industry veterans Bill Ricciardi, Michael Ashton, Stephen Gavin and David D’Astoli, Titeline brought over 30 years of combined experience to the company. Its early work in the Gawler Craton, including projects at Prominent Hill, Carrapateena and Hillside, helped establish Titeline as a reputable Australian contractor. The company expanded to major projects such as Olympic Dam and the Tanami Basin, solidifying its standing in the Australian mining sector.

Titeline specialises in surface and underground diamond drilling, with a focus on deep directional drilling and resource definition. Known for its ability to manage challenging geological environments, the company’s skilled workforce, advanced fleet of drilling rigs and commitment to safety and operational excellence have driven its growth. With projects in countries like Papua New Guinea, Ecuador, Chile and Mongolia, Titeline has further honed its ability to manage complex, large-scale, multi-rig drilling operations worldwide.

Safety, efficiency and hands-free technology

A key driver behind Titeline’s technological innovations has been improving safety standards. Recognising the hazards of manual tasks, such as handling drill rods, Titeline sought to automate these processes to reduce risks to workers. In 2013, the company’s internal design team developed a hydraulic arm that could retrofit to existing rigs, automating the handling of drill rods. This solution, which included a hydraulic plug spinner for secure rod connections, eliminated manual lifting, reduced injury risks and improved safety. Over 60 units have been sold globally, contributing to a safer work environment and greater efficiency.

Titeline went further by developing a fully autonomous underground drill featuring automated rod and semi-automated tube handling. Field-tested with a third-party robotics company, the system has been operational for over 1000 single-operator shifts, diversifying Titeline’s workforce by enabling individuals who are not typically involved in manual tasks to contribute to underground operations.

Key projects and achievements

Titeline’s success goes beyond technological innovation, with significant contributions to mining projects worldwide. A notable example is the company’s work at the Prominent Hill ore body in 2004. Despite challenging ground conditions, Titeline worked closely with local suppliers to develop specialised drill bits and methods, drilling over 200,000m of diamond core while keeping costs within budget. This collaboration led to Titeline being chosen as the sole contractor for the project.

At the Harmony Gold Kili Teke project in Papua New Guinea, Titeline overcame logistical challenges due to difficult terrain. The company designed a mud program with drilling fluids supplier Mudex, which minimised helicopter time and optimised hole stability. This innovation led to a 30% increase in production, allowing Harmony Gold to reset its budget and drill additional meters, contributing to a major resource discovery at Kili Teke.

Overcoming challenges and investing in the future

Despite its achievements, Titeline faces ongoing industry challenges, particularly the shortage of experienced drill operators and technicians. The increasing demand for skilled workers, combined with the shift toward more complex technology-driven operations, has made it difficult to meet staffing needs. However, Titeline views this as an opportunity, investing in training programs to mentor and develop new, “green” operators. By equipping the next generation of drillers with skills to work with advanced technologies, Titeline ensures long-term success and adaptation to industry trends.

The company also faces supply chain constraints, especially when sourcing components for advanced rigs. Shortages of rare earth materials and electrical components from Europe and Japan have required Titeline to plan months in advance for equipment procurement. Despite these challenges, the company maintains strong relationships with trusted suppliers like Hardcore Diamond Products and Mudex to keep its rigs operational and meet client needs.

The road ahead

Titeline Drilling’s commitment to safety, efficiency and innovation positions the company to continue pushing the boundaries of drilling technology. The development of autonomous, intelligent drilling systems represents the future of the industry, where manual labour is minimised, safety is enhanced and drilling operations are more productive and cost-effective. With its deep legacy, ongoing investment in innovation and focus on nurturing the next generation of drillers, Titeline Drilling is poised to lead the future of underground drilling.

For more information or to contact Titeline Drilling, reach Matt Zanette at 0437 928 236 or via email at matthew.z@titelinedrilling.com.