J&S Engineering – Integrity and excellence

J&S Engineering & Maintenance stands as a testament to over three decades of unwavering commitment to quality, innovation and industry leadership. As a proudly family-owned business, J&S Engineering has cultivated a reputation for delivering comprehensive engineering solutions to the mining sector.

Drillrod shop: manufacturing and reclamation excellence

Catering to the demanding needs of blasthole drilling operations, J&S Engineering’s drillrod shop specialises in the manufacture and reclamation of drill consumables. The facility produces a comprehensive range of drill rods up to 8 5/8 OD, including alloy rods upon request.

The shop offers patented bolt-on saver subs, top and bit subs, alloy bull shaft clamps, extended bull shafts, spiral-bladed reamers, water separators and triple-race hardened deck bushes. This division ensures rapid turnaround times for both standard and custom components, minimising downtime for clients.

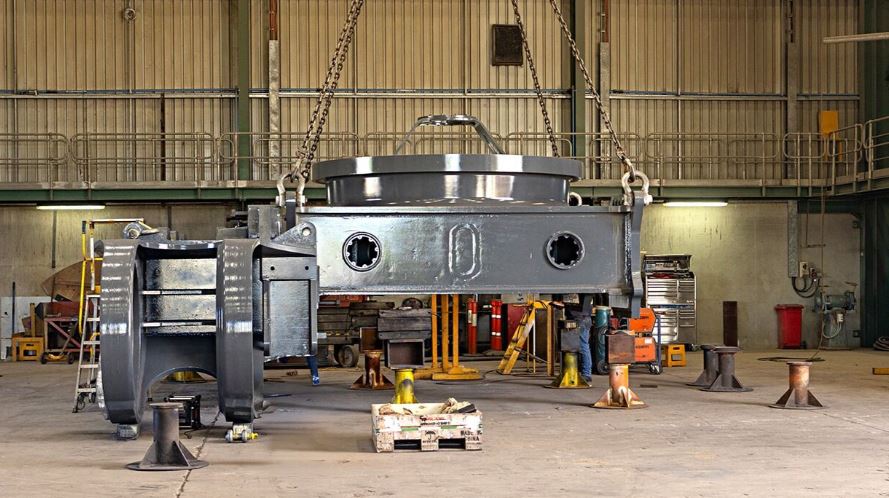

Heavy fabrication shop: robust structural solutions

The heavy fabrication shop is equipped to handle large-scale industrial projects. J&S specialise in refurbishing large earth moving components such as track frames, car bodies, booms, sticks and buckets.

Utilising advanced welding and fabrication techniques, the team ensures that each project meets stringent quality standards and is delivered on time. This division plays a crucial role in extending the operational lifespan of critical mining and earthmoving equipment.

Machining shop: precision engineering capabilities

Equipped with cutting-edge machinery, including a 10 metre Soraluce with a 40t rotating table, two horizontal borers, a vertical borer and a metal spray facility, the extensive CNC and manual machining facility is at the core of operations.

This allows for efficient and precise manufacturing and remanufacturing of large components such as dozer and excavator track frames, equaliser bars, hubs and spindles.

Blast and paint shop: customised surface treatment

J&S Engineering’s blast and paint shop offers a state-of-the-art facility designed to prepare and protect assets for extended service life. The facility boasts a 12.5m long, 6m wide and 5m high chamber, equipped with advanced abrasive blasting technology to ensure thorough surface preparation.

Components undergo meticulous painting processes by trade qualified painters with NACE level one and two coating inspectors. J&S utilise all blast and paint testing equipment to ensure the team meet specifications required.

J&S exemplifies the pinnacle of heavy engineering excellence in the mining industry, delivering integrated solutions that meet the diverse needs of its clientele.

With a steadfast commitment to quality, integrity and customer satisfaction, J&S Engineering continues to set industry benchmarks, ensuring the longevity and reliability of critical industrial equipment across the mining sector.