Maskill undercarriage solutions

Proudly supporting Whitehaven’s journey of excellence

As Whitehaven Coal celebrates its remarkable 25-year milestone in the Australian mining industry, Maskill would like to congratulate them on their outstanding achievements and express their pride in being a trusted partner on Whitehaven’s journey.

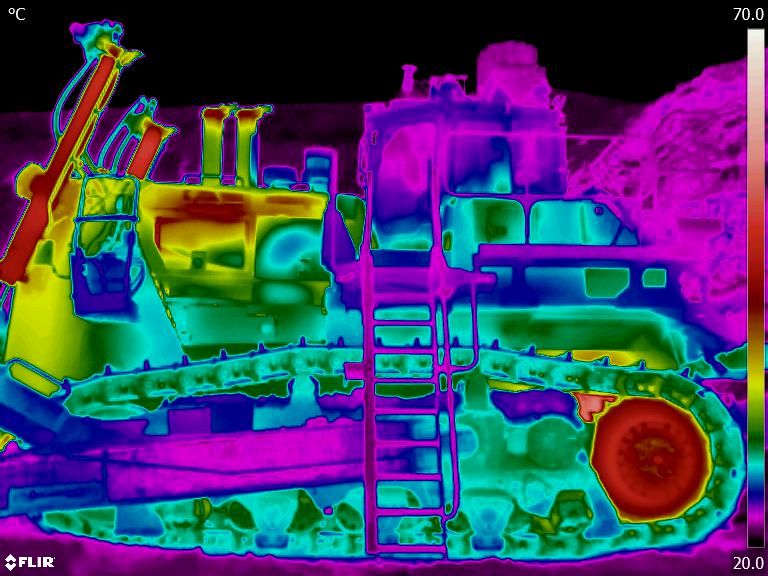

The relationship with Whitehaven began in 2018 at the Maules Creek operation when the company’s fleet of new Cat D11 dozers experienced simultaneous track bush failures.

This critical situation required immediate attention, and the team at Maskill responded by providing loan tracks and sourcing quality used parts that delivered cost-effective repairs with rapid turnaround times. What started as an emergency response quickly evolved into a comprehensive fleet management partnership built on trust, reliability and innovation.

This collaborative approach combined with Whitehaven’s drive for continual improvement has set the tone for the partnership. A prime example is Maskill’s work with Whitehaven’s D475 dozers. These machines initially achieved only 1,500 operating hours before experiencing joint failure — a costly limitation in a high-production environment. Maskill provided rapid solutions fuelled by their dedication to continuous improvement and not accepting the status quo.

In field feedback through CTS inspections was pivotal in the Maskill D475 track, a completely redesigned system engineered specifically for the demanding conditions seen at sites like Whitehaven’s.

The results have been transformative. These purpose designed tracks are now returning for midlife servicing after an impressive 5,000 hours of operation — more than tripling the original lifespan. This dramatic improvement in component longevity has significantly reduced downtime, enhanced productivity and delivered substantial cost savings across Whitehaven’s operations.

Maskill chief executive Shannon Jansen comments on the partnership.

“Our partnership with Whitehaven Coal exemplifies what can be achieved when suppliers and operators collaborate to solve challenges,” he said.

“What began as an emergency response has evolved into a relationship built on mutual respect and innovation.

“We’re particularly proud of our D475 track solution, which has more than tripled component life in Whitehaven’s demanding conditions.

“As they celebrate 25 years of excellence in Australian mining, we’re honoured to have played even a minor role in their success story.”

Understanding the uniquely challenging wear conditions across Whitehaven sites, Maskill have implemented a proactive maintenance program featuring quarterly comprehensive track system (CTS) inspections across their dozer fleets. These regular assessments provide Whitehaven’s maintenance departments with crucial data and insights, ensuring optimal fleet performance and helping identify potential issues before they develop into costly failures.

The partnership extends beyond components and maintenance to include critical operational support.

Recognising the substantial capital investment required for maintaining undercarriage spares, Maskill provide support for both loan tracks and frames for Whitehaven’s Cat D10T, D11T and Komatsu D475 fleets. This service eliminates the need for Whitehaven to have its own rotable spares, freeing up valuable capital while ensuring equipment availability remains uncompromised.

As Whitehaven celebrates 25 years of innovation and excellence in Australian mining, Maskill is honoured to have contributed to their success and look forward to supporting their operations for many years to come.