Broons combination roller is ideal for mining operations

Broons Director, Stuart Bowes, says the Company’s towed Combination Roller is ideal for road maintenance on mine sites and is particularly suited for haul roads with long leads or access roads.

“Broons developed the Combination Roller for maintenance grading, that’s its 1 purpose. It can be ballasted up to 14-tonne and from the seat of the grader it allows the operator to choose between smooth steel roll drum, grid drum or rubber tyres to provide the perfect running surface every time,” he said.

“Our Combination Roller has proven particularly popular with remote mining operations, Shire Councils and road contractors for gravel road maintenance over many decades.”

Recently delivered Combination Rollers are being used for maintenance grading on several mine sites throughout WA with a significant number of units delivered throughout the country over the last few years.

“We’ve been manufacturing and delivering rollers throughout the world for more than 50 years, so we’ve got a pretty good idea what the market demands,” Mr Bowes said.

“It’s a very tough market these days to find operators and anything to make their life better is a bonus.

“Compaction is an absolute necessity in any road but even more so with gravel roads where both the formation and the running surface is totally exposed to the elements. The option to have both a grader and roller operator on separate machines on the one job is a luxury at best. To have just one operator perform both tasks and with no additional engine or complicated electronics on the roller, your maintenance team is going to love the concept.

“There’s a lot of emphasis on the actual mining operation and containing the direct costs but rarely is enough consideration given to the secondary costs around the edges which can make a big impact with minimal effort.

“Using a Combination Roller behind a grader provides a net saving many times larger than the initial outlay and the savings are immediate. Grading and properly compacting mine access roads and long lead haul roads are two good examples.

“Tyre and suspension damage on vehicles is reduced and improved travel times are significant gains when you are moving a lot of ore, staff, supplies and equipment over gravel roads.

“Applying proper compaction to a gravel road during maintenance grading can make a world of difference after heavy rain when roads are opened up far more quickly for use. Those on the ground know only too well the benefit in keeping the wheels rolling.”

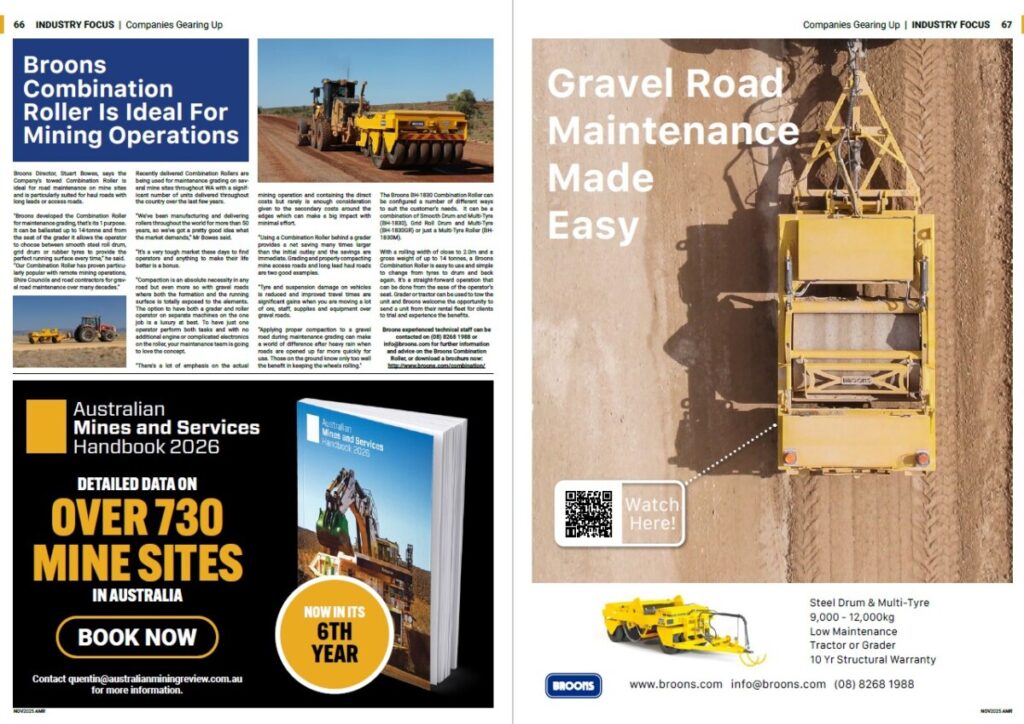

The Broons BH-1830 Combination Roller can be configured a number of different ways to suit the customer’s needs. It can be a combination of Smooth Drum and Multi-Tyre (BH-1830), Grid Roll Drum and Multi-Tyre (BH-1830GR) or just a Multi-Tyre Roller (BH-1830M).

With a rolling width of close to 2.0m and a gross weight of up to 14 tonnes, a Broons Combination Roller is easy to use and simple to change from tyres to drum and back again. It’s a straight-forward operation that can be done from the ease of the operator’s seat. Grader or tractor can be used to tow the unit and Broons welcome the opportunity to send a unit from their rental fleet for clients to trial and experience the benefits.

Broons experienced technical staff can be contacted on (08) 8268 1988 or info@broons.com for further information and advice on the Broons Combination Roller, or download a brochure now: http://www.broons.com/combination/