Complete dust suppression solutions

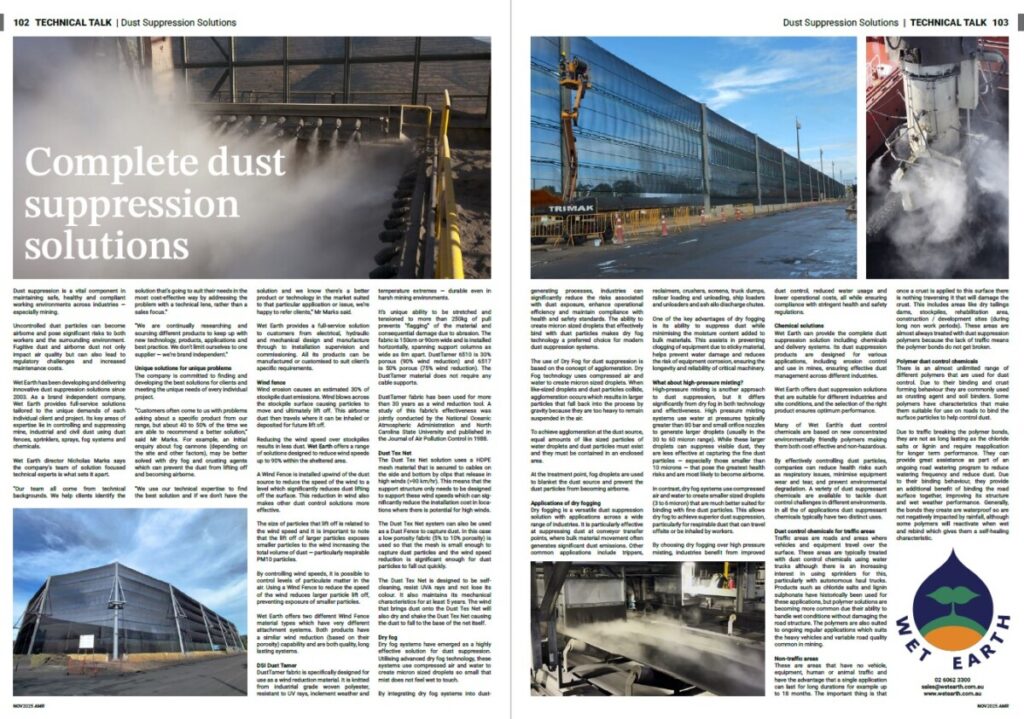

Dust suppression is a vital component in maintaining safe, healthy and compliant working environments across industries — especially mining.

Uncontrolled dust particles can become airborne and pose significant risks to both workers and the surrounding environment. Fugitive dust and airborne dust not only impact air quality but can also lead to regulatory challenges and increased maintenance costs.

Wet Earth has been developing and delivering innovative dust suppression solutions since 2003. As a brand independent company, Wet Earth provides full-service solutions tailored to the unique demands of each individual client and project. Its key areas of expertise lie in controlling and suppressing mine, industrial and civil dust using dust fences, sprinklers, sprays, fog systems and chemicals.

Wet Earth director Nicholas Marks says the company’s team of solution focused technical experts is what sets it apart.

“Our team all come from technical backgrounds. We help clients identify the solution that’s going to suit their needs in the most cost-effective way by addressing the problem with a technical lens, rather than a sales focus.”

“We are continually researching and sourcing different products to keep up with new technology, products, applications and best practice. We don’t limit ourselves to one supplier — we’re brand independent.”

Unique solutions for unique problems

The company is committed to finding and developing the best solutions for clients and meeting the unique needs of every individual project.

“Customers often come to us with problems asking about a specific product from our range, but about 40 to 50% of the time we are able to recommend a better solution,” said Mr Marks. For example, an initial enquiry about fog cannons (depending on the site and other factors), may be better solved with dry fog and crusting agents which can prevent the dust from lifting off and becoming airborne.

“We use our technical expertise to find the best solution and if we don’t have the solution and we know there’s a better product or technology in the market suited to that particular application or issue, we’re happy to refer clients,” Mr Marks said.

Wet Earth provides a full-service solution to customers from electrical, hydraulic and mechanical design and manufacture through to installation supervision and commissioning. All its products can be manufactured or customised to suit client’s specific requirements.

Wind fence

Wind erosion causes an estimated 30% of stockpile dust emissions. Wind blows across the stockpile surface causing particles to move and ultimately lift off. This airborne dust then travels where it can be inhaled or deposited for future lift off.

Reducing the wind speed over stockpiles results in less dust. Wet Earth offers a range of solutions designed to reduce wind speeds up to 90% within the sheltered area.

A Wind Fence is installed upwind of the dust source to reduce the speed of the wind to a level which significantly reduces dust lifting off the surface. This reduction in wind also makes other dust control solutions more effective.

The size of particles that lift off is related to the wind speed and it is important to note that the lift off of larger particles exposes smaller particles to the wind increasing the total volume of dust — particularly respirable PM10 particles.

By controlling wind speeds, it is possible to control levels of particulate matter in the air. Using a Wind Fence to reduce the speed of the wind reduces larger particle lift off, preventing exposure of smaller particles.

Wet Earth offers two different Wind Fence material types which have very different attachment systems. Both products have a similar wind reduction (based on their porosity) capability and are both quality, long lasting systems.

DSI Dust Tamer

DustTamer fabric is specifically designed for use as a wind reduction material. It is knitted from industrial grade woven polyester, resistant to UV rays, inclement weather and temperature extremes — durable even in harsh mining environments.

It’s unique ability to be stretched and tensioned to more than 250kg of pull prevents “flagging” of the material and consequential damage due to abrasion. The fabric is 150cm or 90cm wide and is installed horizontally, spanning support columns as wide as 8m apart. DustTamer 6510 is 30% porous (90% wind reduction) and 6517 is 50% porous (75% wind reduction). The DustTamer material does not require any cable supports.

DustTamer fabric has been used for more than 30 years as a wind reduction tool. A study of this fabric’s effectiveness was jointly conducted by the National Oceanic Atmospheric Administration and North Carolina State University and published in the Journal of Air Pollution Control in 1988.

Dust Tex Net

The Dust Tex Net solution uses a HDPE mesh material that is secured to cables on the side and bottom by clips that release in high winds (>90 km/hr). This means that the support structure only needs to be designed to support these wind speeds which can significantly reduce the installation cost in locations where there is potential for high winds.

The Dust Tex Net system can also be used as a Dust Fence to capture dust. In this case a low porosity fabric (5% to 10% porosity) is used so that the mesh is small enough to capture dust particles and the wind speed reduction is significant enough for dust particles to fall out quickly.

The Dust Tex Net is designed to be self-cleaning, resist UVA rays and not lose its colour. It also maintains its mechanical characteristics for at least 5 years. The wind that brings dust onto the Dust Tex Net will also dry and shake the Dust Tex Net causing the dust to fall to the base of the net itself.

Dry fog

Dry fog systems have emerged as a highly effective solution for dust suppression. Utilising advanced dry fog technology, these systems use compressed air and water to create micron sized droplets so small that mist does not feel wet to touch.

By integrating dry fog systems into dust-generating processes, industries can significantly reduce the risks associated with dust exposure, enhance operational efficiency and maintain compliance with health and safety standards. The ability to create micron sized droplets that effectively bind with dust particles makes dry fog technology a preferred choice for modern dust suppression systems.

The use of Dry Fog for dust suppression is based on the concept of agglomeration. Dry Fog technology uses compressed air and water to create micron sized droplets. When like-sized droplets and dust particles collide, agglomeration occurs which results in larger particles that fall back into the process by gravity because they are too heavy to remain suspended in the air.

To achieve agglomeration at the dust source, equal amounts of like sized particles of water droplets and dust particles must exist and they must be contained in an enclosed area.

At the treatment point, fog droplets are used to blanket the dust source and prevent the dust particles from becoming airborne.

Applications of dry fogging

Dry fogging is a versatile dust suppression solution with applications across a wide range of industries. It is particularly effective at suppressing dust at conveyor transfer points, where bulk material movement often generates significant dust emissions. Other common applications include trippers, reclaimers, crushers, screens, truck dumps, railcar loading and unloading, ship loaders and unloaders and ash silo discharge chutes.

One of the key advantages of dry fogging is its ability to suppress dust while minimising the moisture content added to bulk materials. This assists in preventing clogging of equipment due to sticky material, helps prevent water damage and reduces the risk of equipment corrosion, ensuring the longevity and reliability of critical machinery.

What about high-pressure misting?

High-pressure misting is another approach to dust suppression, but it differs significantly from dry fog in both technology and effectiveness. High pressure misting systems use water at pressures typically greater than 80 bar and small orifice nozzles to generate larger droplets (usually in the 30 to 60 micron range). While these larger droplets can suppress visible dust, they are less effective at capturing the fine dust particles — especially those smaller than 10 microns — that pose the greatest health risks and are most likely to become airborne.

In contrast, dry fog systems use compressed air and water to create smaller sized droplets (3 to 6 micron) that are much better suited for binding with fine dust particles. This allows dry fog to achieve superior dust suppression, particularly for respirable dust that can travel offsite or be inhaled by workers.

By choosing dry fogging over high pressure misting, industries benefit from improved dust control, reduced water usage and lower operational costs, all while ensuring compliance with stringent health and safety regulations.

Chemical solutions

Wet Earth can provide the complete dust suppression solution including chemicals and delivery systems. Its dust suppression products are designed for various applications, including erosion control and use in mines, ensuring effective dust management across different industries.

Wet Earth offers dust suppression solutions that are suitable for different industries and site conditions, and the selection of the right product ensures optimum performance.

Many of Wet Earth’s dust control chemicals are based on new concentrated environmentally friendly polymers making them both cost effective and non-hazardous.

By effectively controlling dust particles, companies can reduce health risks such as respiratory issues, minimise equipment wear and tear, and prevent environmental degradation. A variety of dust suppressant chemicals are available to tackle dust control challenges in different environments. In all the of applications dust suppressant chemicals typically have two distinct uses.

Dust control chemicals for traffic areas

Traffic areas are roads and areas where vehicles and equipment travel over the surface. These areas are typically treated with dust control chemicals using water trucks although there is an increasing interest in using sprinklers for this, particularly with autonomous haul trucks. Products such as chloride salts and lignin sulphonate have historically been used for these applications, but polymer solutions are becoming more common due their ability to handle wet conditions without damaging the road structure. The polymers are also suited to ongoing regular applications which suits the heavy vehicles and variable road quality common in mining.

Non-traffic areas

These are areas that have no vehicle, equipment, human or animal traffic and have the advantage that a single application can last for long durations for example up to 18 months. The important thing is that once a crust is applied to this surface there is nothing traversing it that will damage the crust. This includes areas like dry tailings dams, stockpiles, rehabilitation area, construction / development sites (during long non work periods). These areas are almost always treated with dust suppression polymers because the lack of traffic means the polymer bonds do not get broken.

Polymer dust control chemicals

There is an almost unlimited range of different polymers that are used for dust control. Due to their binding and crust forming behaviour they are commonly used as crusting agent and soil binders. Some polymers have characteristics that make them suitable for use on roads to bind the surface particles to help control dust.

Due to traffic breaking the polymer bonds, they are not as long lasting as the chloride salts or lignin and require reapplication for longer term performance. They can provide great assistance as part of an ongoing road watering program to reduce watering frequency and reduce dust. Due to their binding behaviour, they provide an additional benefit of binding the road surface together, improving its structure and wet weather performance. Generally, the bonds they create are waterproof so are not negatively impacted by rainfall, although some polymers will reactivate when wet and rebind which gives them a self-healing characteristic.

SOURCE:

Wet Earth

02 6062 3300