Mining’s digital revolution

Stay connected and protected

In the high-risk environment of mining, safety will always stand as the top priority. In the face of a rapidly evolving landscape, how miners approach safety must also adapt.

Technology and innovation are at the helm of this revolution, with the widespread adoption of automation and data-driven solutions driving efficiency and safety.

Amidst this profound change, one company is creating ‘future-now’ solutions to keep operations, people and infrastructure connected.

Orro Group has developed a range of professional and managed services across security, network, cloud and unified communications to deliver greater safety, security and efficiency to businesses of all sizes.

Making automation accessible

Orro Group chief technology officer Stuart Long says before automation, high-risk conditions onsite often meant production in certain areas would have to be shut down to protect worker safety.

“That would lead to a mine site operating well below optimal efficiency levels, generally less than 70%,” he said.

The process of shutting down operations and then restarting, and often repeating the cycle, is incredibly costly in terms of both capital and time.

“What we’re seeing with automation is you can now start to operate at about 90% efficiency purely because the machines and devices you’re using don’t have human operators, which greatly minimises risk,” Mr Long said.

Automation is now becoming considered a requirement to be a truly efficient miner with automation integration driving not only operational efficiency but driving down capital costs and increasing profit margins.

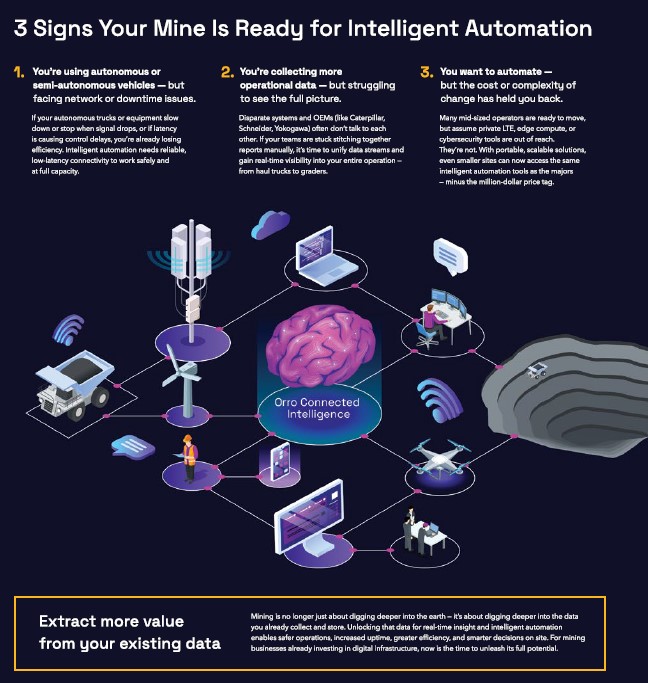

For company’s wishing to keep up with the rapid uptake of automation this has meant a complete overhaul of their technology suites — often a costly and time-consuming venture. This isn’t a major problem for large companies, who have the budgets and the time to make these changes. For the smaller miner however, this transition can be challenging to navigate.

“To make the transitions you need things like private LTE networks because you need high performance, low latency environments,” Mr Long said.

“You can imagine if you’re driving a truck around one of these sites, you can’t wait for that packet to transit through a cloud data centre and come back — there’s too much latency and the potential for problems occurring is just too great during that period.”

“Now we’re starting to see the need for what we call TROC’s, technology remote operation centres, on site potentially then with suppliers or managed service providers.”

Orro has a private LTE solution, capable of accelerating intelligent connectivity and supporting automation, and has now helped many smaller miners through this change.

“Now what we’re seeing is the cost of that technology is making it extremely attractive for those miners to start the move over to automation,” Mr Long said.

“No longer is it a Telstra level type service costing millions of dollars, you can now see it being integrated across many smaller operations — it’s far more accessible.”

Orro’s private LTE solution is supported by portable edge data centre technology which provides secure, high-bandwidth and low latency networks directly to the source. Mobile, secure and scalable, the standardised 5G devices used to establish the network integrate seamlessly with operations onsite.

Securely connected, everywhere

Data security is another major concern amongst miners. Data breaches can lead to compromised safety and compliance, major operational shutdown and the release of highly sensitive data — leading to major disruption and financial loss.

“With Orro’s OT Cyber Operations Centre or Security Operations Centre we’re able now to provide a critical layer of security to our solutions,” Mr Long said.

“What this enables us to not only connect and start to pull that data, but then to protect that data as we do it to ensure that users are not exposed to security risks.”

“We’re now integrating the same data we pull for telemetry around networks and information around security to be able to provide what we call production assurance platforms.”

Network connectivity issues are renowned across mine sites due to their isolated locations. Maintaining connectivity is crucial to not only ensuring data security, but also to keep operations running unhindered. For example, autonomous vehicles are designed to slow down in areas of poor network signal so there is less potential for accident occurrence. In many cases, when one truck loses signal and stops, all the trucks on site will stop.

Orro’s platforms monitor how operations are running and provide feedback where there is a poor network connectivity — stopping those outages from occurring, keeping vehicles moving and driving up utilisation of services within that mine itself.

Orro developed its Secure Access Service Edge (SASE) to provide reliable, secure connectivity to even the most remote sites. SASE combines the intelligent capabilities of SD-WAN, the features of state-of-the-art security technologies and the vigilance of our Security Operations Centre (SOC) to provide a fully managed, cloud-delivered offering.

“We were faced with the challenge getting these computer or networking devices out to these sites. To address this, we’ve combined all of the technologies into a single edge data centre which includes power cooling,” Mr Long said.

“These devices are a true plug and play solution built to withstand the dusty and wet conditions onsite. We are now seeing this computer technology used across a wide range of different industries due to its durability and reliability.

By packaging a number of solutions together, Orro is creating new technology services that integrates easily into existing IT environments. By pulling together a number of different data sets from different OEMs, Orro now gives customers the ability to see across a wide range of their operational capability.

In mining, it has previously been time consuming and difficult to bring these data sets together. The ability to do so efficiently on site enables Orro to give users a multi-dimensional view of their assets running on a single site — from dump trucks to graders.

“We have end to end traceability. We can monitor if somebody’s powered a machine on or even open a lid on the box in transit. We can then hook these devices securely into those customer environments and run multiple applications on these edge data centres or network services,” Mr Long said.

“Miners wany to be able to work in a disconnected environment and this allows us to do just that, even if they have no connectivity or they lose connectivity out of the site.”

What that looks like on site

Typically, there are a number of vehicles, both autonomous and manned, operating on site at any given time. Monitoring the movement of these machines is critical to ensuring no collisions or accidents occur.

However, when these machines are operational, they can interfere with network connectivity. For example, strong vibrations — something that is not uncommon in powerful mining equipment — can interfere with the ability to track a device.

As a safety measure, autonomous vehicles are programmed to come to a stop when connectivity is lost and, as imaginable, if connectivity is lost every time a particular machine runs this can severely hinder operations.

“It’s very difficult to run in those operating environments,” Mr Long said.

“What we’re doing is pulling these events together so users can see where these problems are occurring — which enables the site to get back online much quicker.

“Customers want to understand what’s going on from a network perspective and quite often, they’ll find the network is up but they’re getting poor performance.”

By getting feedback in real time from devices that are operating on and around site, users can see on a heat map where there is poor connectivity and pinpoint problem areas.

“There are many reasons these interferences could be occurring, for example, ore could be stockpiled in front of a network tower which is blocking the signal,” Mr long said.

“Something so simple has the capacity to bringdown the entire mine. The ability to track this in real time is a new advancement and its one that can signifcantly benefit mine sites.”

Orro continues to help companies stay connected across complex operations. From real-time tracking to secure cloud services, its solutions optimise efficiency, improve data security and support mission-critical infrastructure.

Source:

Orro Group

1300 900 000