Modec Connect Solution

The smart future of valve monitoring

For decades, Modec has collaborated across industries to offer versatile portable actuators. By understanding market demands, they have pioneered a monitoring solution aligned with Industry 4.0 and IoT technologies.

Key features:

- Seamless integration: A smart sensor connects to Modec actuators without any modifications to your installation.

- Data management made simple: Transmits torque, speed and rotation data via Bluetooth to a secure mobile and web application for effortless analysis.

- Team organisation: Assign user roles with varying access levels to streamline operations.

- Valve insights on-the-go: Input and access critical valve data anywhere, anytime.

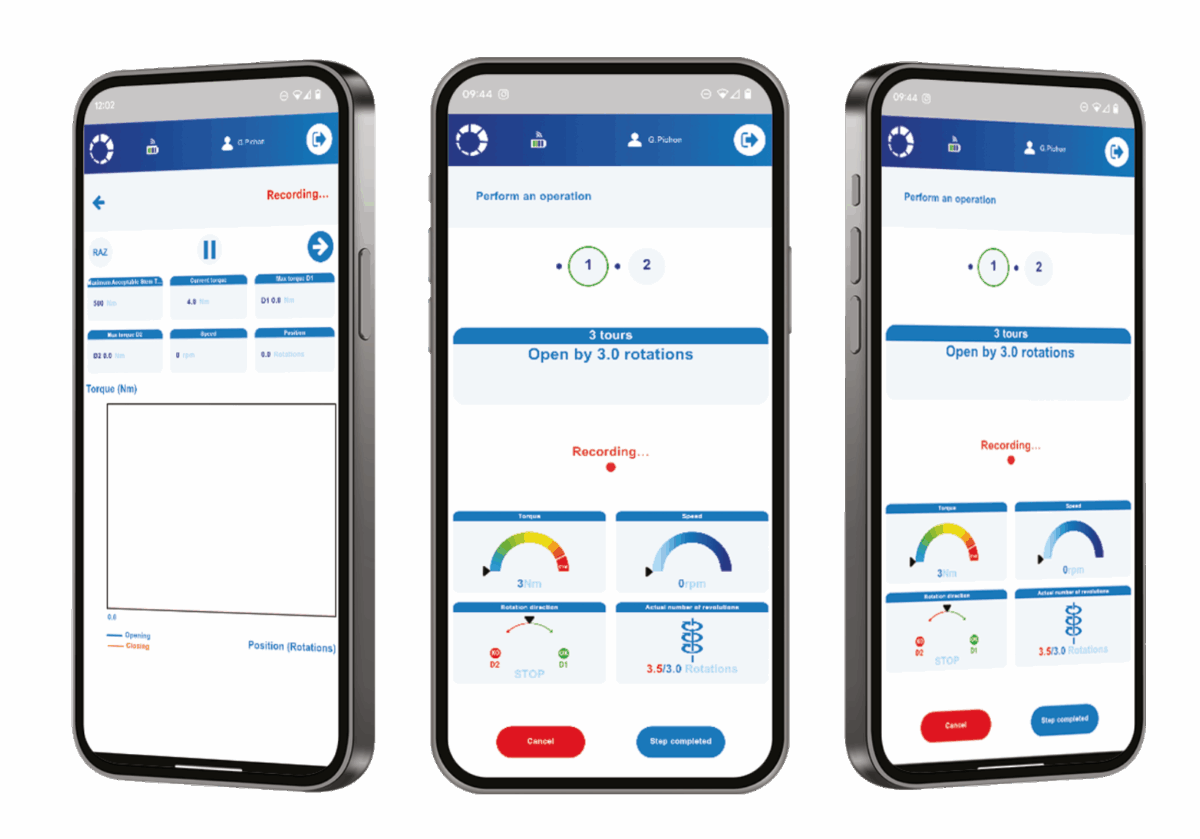

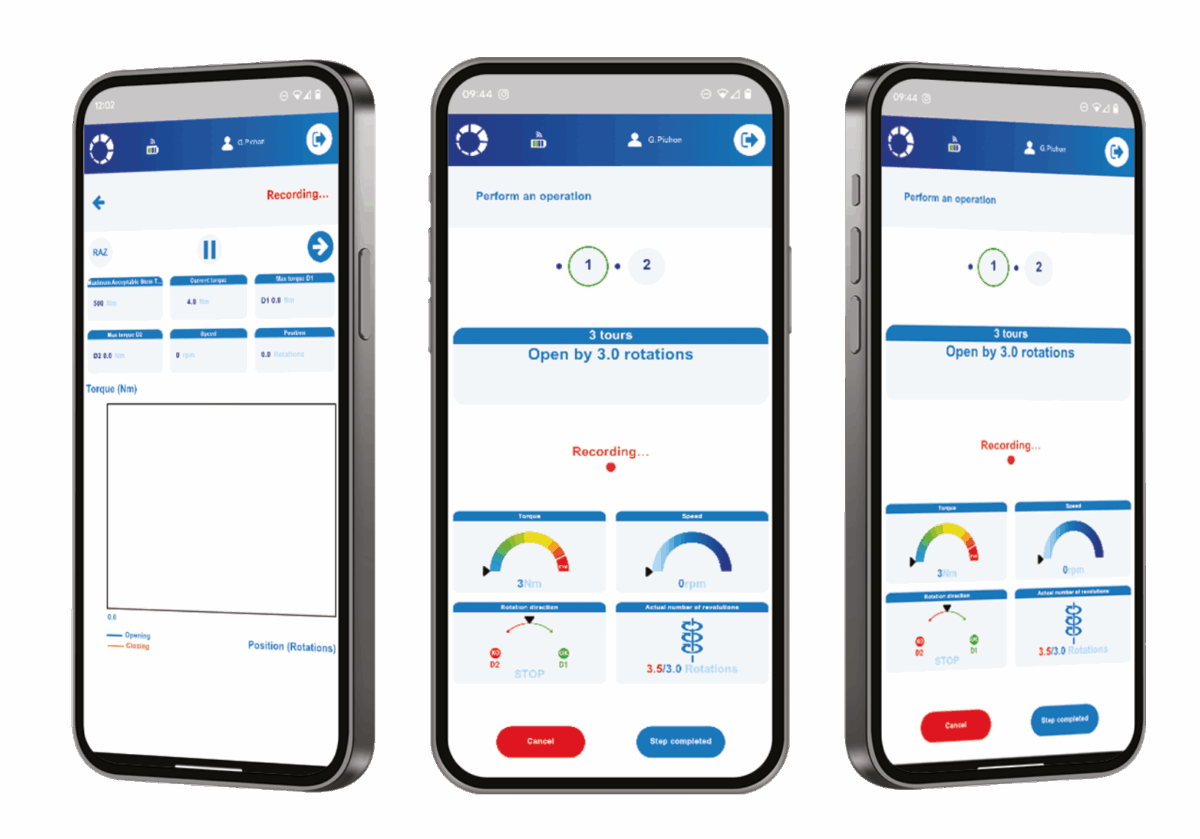

Effortless data collection and analysis

What does Modec Connect measure

- Free mode: Real-time measurement of torque, speed and revolutions.

- Guided mode: Provides steps for comparative analysis of valve conditions over time.

Advanced reporting:

- Export professional PDF reports to share insights and maintain operation records.

- Analyse performance curves with simplified visualisations for clear trends.

The LTN67 Sensor in Modec Connect measures torque and speed, transmitting real-time data to the mobile app via Bluetooth. Lightweight and compatible with all Modec actuators, it empowers efficient monitoring of manual valve networks.

4 good reasons to monitor your manual valves

While industries continue to digitise their automatic valves and processes to streamline data collection, improve maintenance and reduce costs, manual valves often remain unmonitored with little to no data. Yet, despite their large numbers and involvement in critical processes, they are frequently overlooked. So why focus only on monitoring automatic valves and not manual ones

Here are compelling reasons why manual valves should also be monitored.

Reduction of unexpected shutdowns: By monitoring valve performance and condition, maintenance and repairs can be carried out and planned according to actual needs, rather than by assumption or routine schedules. This avoids unnecessary parts replacements and interventions, reduces costs and improves overall process control, ensuring smooth and efficient equipment operation without unexpected disruptions.

Extended equipment lifespan: Through non-intrusive installations, valves can be regularly monitored without disrupting operations, allowing early detection of the first signs of wear. By addressing issues before they worsen, equipment can be maintained more efficiently, extending its lifespan and avoiding costly breakdowns or premature replacements.

Track your work: By storing valve operation data, it becomes easier to share information with your team, facilitating performance verification and problem identification. This not only speeds up troubleshooting but also improves team collaboration and makes training new staff more effective.

Preparing for tomorrow’s innovations: By collecting data today, you lay the groundwork for future tools and technologies, such as AI, which is already entering the industrial sector. The more data you collect now, the more accurate and insightful future analyses will be, enabling smarter decision-making and predictive maintenance.

Field Machine Tools are the Australian distributor partner of Modec Pneumatic Motors & Portable Valve Actuators and can be contacted on 1300 FMT FMT (1300 368 368) or sales@fmt.com.au