Proven performance and smarter savings with ITR Pacific’s Futura GET range

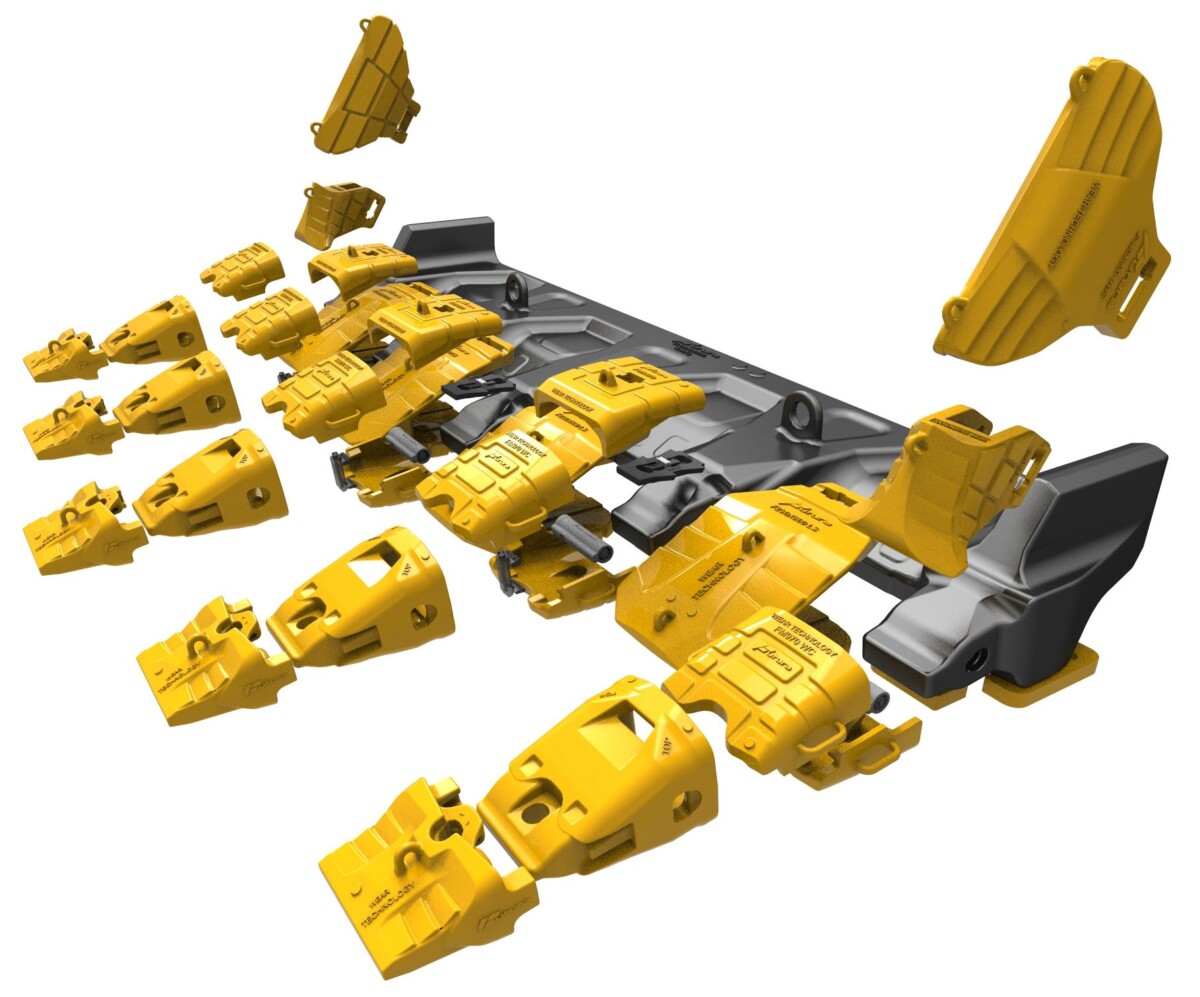

For mining operations, productivity, safety, and cost control all come down to one key factor — performance at the ground face. That’s where ITR Pacific’s Futura Ground Engaging Tools (GET) deliver a distinct advantage, providing a quality direct replacement for leading OEM wear systems such as ESCO™, Hensley™, Komatsu™, Bradken™ and CAT™.

Engineered for safer handling, higher performance and measurable total cost savings, the Futura range combines decades of innovation with modern design. With Futura’s Direct Replacement Parts (DRP), operations can seamlessly transition from OEM wear products without the costly and time-consuming process of change management. When OEM patents expire and manufacturers push “new and improved” systems to re-lock customers into their latest proprietary designs, Futura offers a better path — maintaining compatibility and performance, without the expense or disruption.

Since 1967, BYG Futura has been engineering and manufacturing high-quality GET solutions trusted around the world. As part of the ITR Group of Companies since 2014, Futura products benefit from global research, development and supply chain excellence. ITR Pacific, the authorised distributor for Australia, New Zealand and Papua New Guinea, complements this range with a full suite of mining and construction components, including Undercarriage, Machine Parts, Engine Parts and Filtration.

ITR Pacific’s comprehensive GET, and wear product range supports all major equipment types — from face shovels, excavators and cable shovels through to draglines, dozers, graders and wheel loaders. Each solution is built to deliver maximum wear resistance, extend machine life and minimise total ownership cost, protecting assets and improving uptime across operations.

With a knowledgeable local team and years of field experience, ITR Pacific offers more than just parts — they provide a reliable wear management partnership. So, whether you’re seeking safer installation systems, longer wear life or a more cost-effective alternative to OEM supply chains, it’s time to put Futura GET to the test.

Give ITR Pacific the opportunity to prove what so many in the industry already know —Futura wear products perform to the highest level, with less downtime and greater savings.