Shaping the future with aerial and underground LiDAR

Having high-accuracy and detailed data is crucial to optimal mine planning and monitoring. Advanced LiDAR technology provides precise 3D data to make mine surveying faster, safer and more efficient.

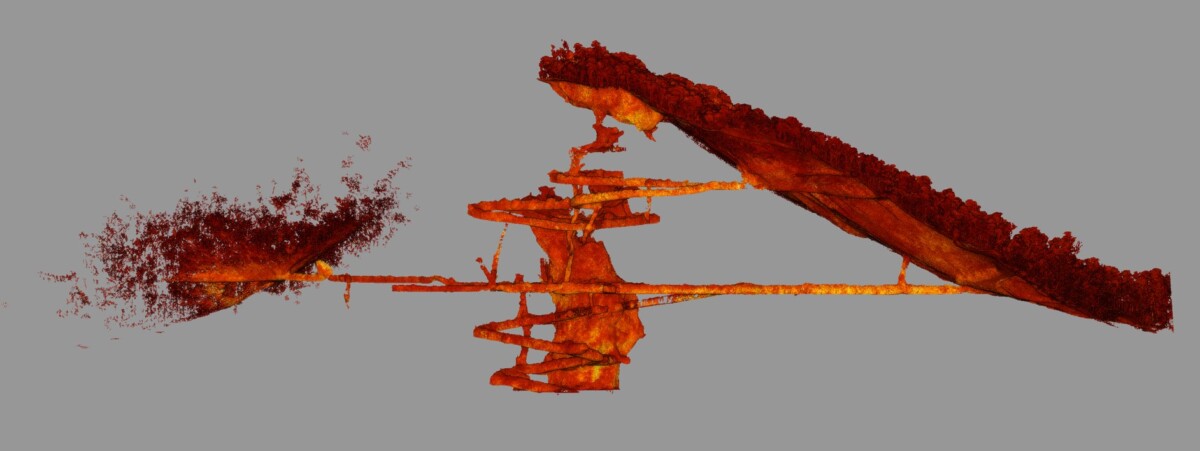

Southern LiDAR specialises in, but is not limited to, underground mine mapping using advanced LiDAR technology. Its expertise allows its team to create highly accurate, detailed 3D models of mine tunnels and shafts, ensuring precise mapping even in challenging underground environments.

By utilising LiDAR, the company enhances safety, streamline operations and provides valuable insights for efficient mine planning and resource management —while minimising risks and improving compliance with safety regulations. The company’s focus on underground mapping helps optimise mining processes and supports better decision-making for long-term success.

Southern LiDAR combines advanced Emesent Hovermap technology with flexible deployment methods to make detailed scanning possible in the toughest environments. Whether it’s carried by hand, mounted on a vehicle, lowered down a shaft or flown by drone, Southern LiDAR’s systems capture rich, reliable datasets safely and efficiently.

Southern LiDAR director and chief remote pilot Jake Hartwig says as a small, family-owned business, the company focuses on providing personalised services and building strong, trusting relationships with clients.

“Our team is dedicated to delivering quality and attention to detail, ensuring every project gets the care it deserves,” he said.

“Over the past ten years of being involved in the mining industry, I have become increasingly intrigued by the power of technology, particularly LiDAR scanning. In the last six years, my focus has shifted more towards LiDAR capture, where I have recognised the significant benefits it offers in enhancing safety, efficiency and precision in mining operations.”

“This experience ignited my curiosity about LiDAR’s potential applications beyond mining, leading me to explore how this innovative technology can revolutionise various industries. I’m passionate about leveraging LiDAR to drive innovation and improve safety across a wide range of fields.”

LiDAR scanning provides far more than basic measurements. The dense point clouds collected reveal details critical for mining, geotechnical and infrastructure decision-making — from structural mapping to stress analysis.

Key outcomes include:

- Clear mapping of underground development and services

- Structural interpretation of rock features and voids

- Assessment of excavation performance and rock mass behaviour

- Identification of principal stress directions

- Detection of restricted access or clearance issues

- Insight into the geometry and stability of stopes, chambers and other excavations

Scanning capability covers:

- Entire underground operations

- Shafts, raises, ore passes and vertical infrastructure

- Large-scale excavations and chambers

- Inaccessible or hazardous voids and collapses

- Historic or abandoned workings

- Surface infrastructure and assets

Southern LiDAR can enhance your operational efficiency by providing high-resolution LiDAR data for precise mapping of both above and below-ground infrastructure. This detailed data supports improved planning, design and optimisation, allowing for accurate volume calculations, resource estimations and identification of critical areas. It also aids in hazard detection, such as unstable ground, structural weaknesses and potential safety risks, enabling proactive measures to ensure both safety and productivity across various industries.

Southern LiDAR turns complex scan data into accurate, georeferenced 3D models, giving operators the confidence to plan, design and work safely in environments that can’t be fully understood by traditional methods.