Stope bollards

Raising the standard for underground mine safety

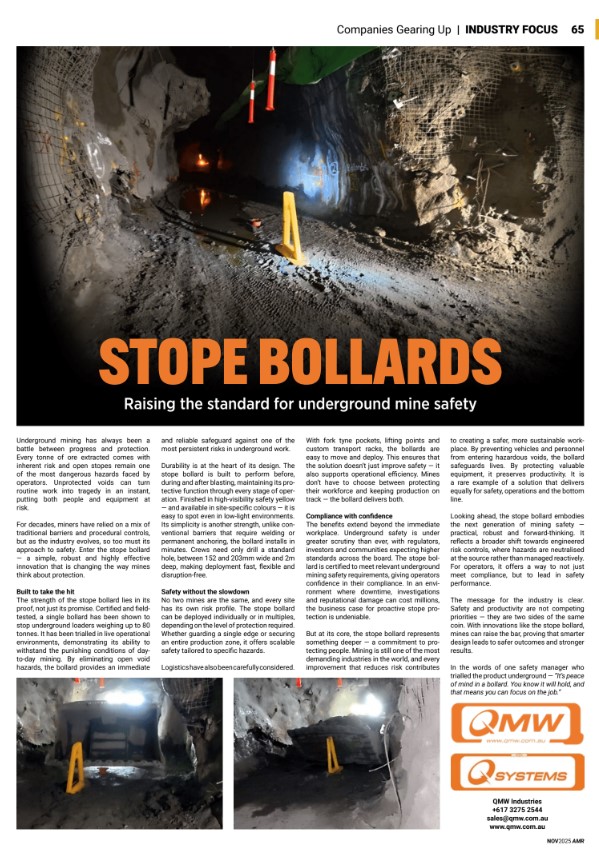

Underground mining has always been a battle between progress and protection. Every tonne of ore extracted comes with inherent risk and open stopes remain one of the most dangerous hazards faced by operators. Unprotected voids can turn routine work into tragedy in an instant, putting both people and equipment at risk.

For decades, miners have relied on a mix of traditional barriers and procedural controls, but as the industry evolves, so too must its approach to safety. Enter the stope bollard — a simple, robust and highly effective innovation that is changing the way mines think about protection.

Built to take the hit

The strength of the stope bollard lies in its proof, not just its promise. Certified and field-tested, a single bollard has been shown to stop underground loaders weighing up to 80 tonnes. It has been trialled in live operational environments, demonstrating its ability to withstand the punishing conditions of day-to-day mining. By eliminating open void hazards, the bollard provides an immediate and reliable safeguard against one of the most persistent risks in underground work.

Durability is at the heart of its design. The stope bollard is built to perform before, during and after blasting, maintaining its protective function through every stage of operation. Finished in high-visibility safety yellow — and available in site-specific colours — it is easy to spot even in low-light environments. Its simplicity is another strength, unlike conventional barriers that require welding or permanent anchoring, the bollard installs in minutes. Crews need only drill a standard hole, between 152 and 203mm wide and 2m deep, making deployment fast, flexible and disruption-free.

Safety without the slowdown

No two mines are the same, and every site has its own risk profile. The stope bollard can be deployed individually or in multiples, depending on the level of protection required. Whether guarding a single edge or securing an entire production zone, it offers scalable safety tailored to specific hazards.

Logistics have also been carefully considered. With fork tyne pockets, lifting points and custom transport racks, the bollards are easy to move and deploy. This ensures that the solution doesn’t just improve safety — it also supports operational efficiency. Mines don’t have to choose between protecting their workforce and keeping production on track — the bollard delivers both.

Compliance with confidence

The benefits extend beyond the immediate workplace. Underground safety is under greater scrutiny than ever, with regulators, investors and communities expecting higher standards across the board. The stope bollard is certified to meet relevant underground mining safety requirements, giving operators confidence in their compliance. In an environment where downtime, investigations and reputational damage can cost millions, the business case for proactive stope protection is undeniable.

But at its core, the stope bollard represents something deeper — a commitment to protecting people. Mining is still one of the most demanding industries in the world, and every improvement that reduces risk contributes to creating a safer, more sustainable workplace. By preventing vehicles and personnel from entering hazardous voids, the bollard safeguards lives. By protecting valuable equipment, it preserves productivity. It is a rare example of a solution that delivers equally for safety, operations and the bottom line.

Looking ahead, the stope bollard embodies the next generation of mining safety — practical, robust and forward-thinking. It reflects a broader shift towards engineered risk controls, where hazards are neutralised at the source rather than managed reactively. For operators, it offers a way to not just meet compliance, but to lead in safety performance.

The message for the industry is clear. Safety and productivity are not competing priorities — they are two sides of the same coin. With innovations like the stope bollard, mines can raise the bar, proving that smarter design leads to safer outcomes and stronger results.

In the words of one safety manager who trialled the product underground — “It’s peace of mind in a bollard. You know it will hold, and that means you can focus on the job.”

+617 3275 2544