When failure is not an option

As the backbone of Australia’s heavy industries, metallurgy and mining demand electrical infrastructure that performs flawlessly in the harshest conditions. When every hour of downtime can cost tens of thousands of dollars, reliability isn’t negotiable — it’s the difference between profit and loss.

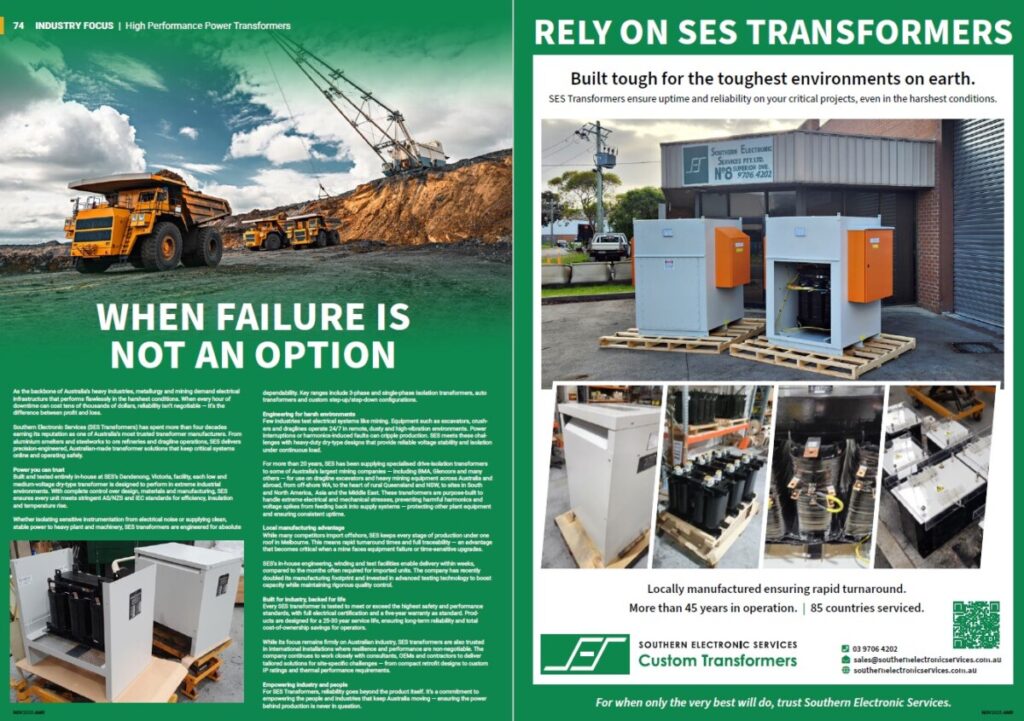

Southern Electronic Services (SES Transformers) has spent more than four decades earning its reputation as one of Australia’s most trusted transformer manufacturers. From aluminium smelters and steelworks to ore refineries and dragline operations, SES delivers precision-engineered, Australian-made transformer solutions that keep critical systems online and operating safely.

Power you can trust

Built and tested entirely in-house at SES’s Dandenong, Victoria, facility, each low and medium-voltage dry-type transformer is designed to perform in extreme industrial environments. With complete control over design, materials and manufacturing, SES ensures every unit meets stringent AS/NZS and IEC standards for efficiency, insulation and temperature rise.

Whether isolating sensitive instrumentation from electrical noise or supplying clean, stable power to heavy plant and machinery, SES transformers are engineered for absolute dependability. Key ranges include 3-phase and single-phase isolation transformers, auto transformers and custom step-up/step-down configurations.

Engineering for harsh environments

Few industries test electrical systems like mining. Equipment such as excavators, crushers and draglines operate 24/7 in remote, dusty and high-vibration environments. Power interruptions or harmonics-induced faults can cripple production. SES meets these challenges with heavy-duty dry-type designs that provide reliable voltage stability and isolation under continuous load.

For more than 20 years, SES has been supplying specialised drive-isolation transformers to some of Australia’s largest mining companies — including BMA, Glencore and many others — for use on dragline excavators and heavy mining equipment across Australia and abroad, from off-shore WA, to the heart of rural Queensland and NSW, to sites in South and North America, Asia and the Middle East. These transformers are purpose-built to handle extreme electrical and mechanical stresses, preventing harmful harmonics and voltage spikes from feeding back into supply systems — protecting other plant equipment and ensuring consistent uptime.

Local manufacturing advantage

While many competitors import offshore, SES keeps every stage of production under one roof in Melbourne. This means rapid turnaround times and full traceability — an advantage that becomes critical when a mine faces equipment failure or time-sensitive upgrades.

SES’s in-house engineering, winding and test facilities enable delivery within weeks, compared to the months often required for imported units. The company has recently doubled its manufacturing footprint and invested in advanced testing technology to boost capacity while maintaining rigorous quality control.

Built for industry, backed for life

Every SES transformer is tested to meet or exceed the highest safety and performance standards, with full electrical certification and a five-year warranty as standard. Products are designed for a 25-30 year service life, ensuring long-term reliability and total cost-of-ownership savings for operators.

While its focus remains firmly on Australian industry, SES transformers are also trusted in international installations where resilience and performance are non-negotiable. The company continues to work closely with consultants, OEMs and contractors to deliver tailored solutions for site-specific challenges — from compact retrofit designs to custom IP ratings and thermal performance requirements.

Empowering industry and people

For SES Transformers, reliability goes beyond the product itself. It’s a commitment to empowering the people and industries that keep Australia moving — ensuring the power behind production is never in question.