Supporting Olympic Dam with safer civil

Established in 2021, RMK Civil Construction has grown rapidly, completing more than 150 projects worth $150m in the mining sector. As a boutique civil construction company, it offers the agility to deliver projects faster without compromising on exceptional outcomes or safety, ensuring every project runs smoothly and efficiently.

RMK Civil leads the way in the Australian mining industry, delivering safer civil construction, expert concrete installation and remediation, which aligns with its earthworks solutions. With a commitment to exceptional outcomes and efficient project delivery, its team ensures your operations run smoothly.

Supporting operations at Olympic Dam

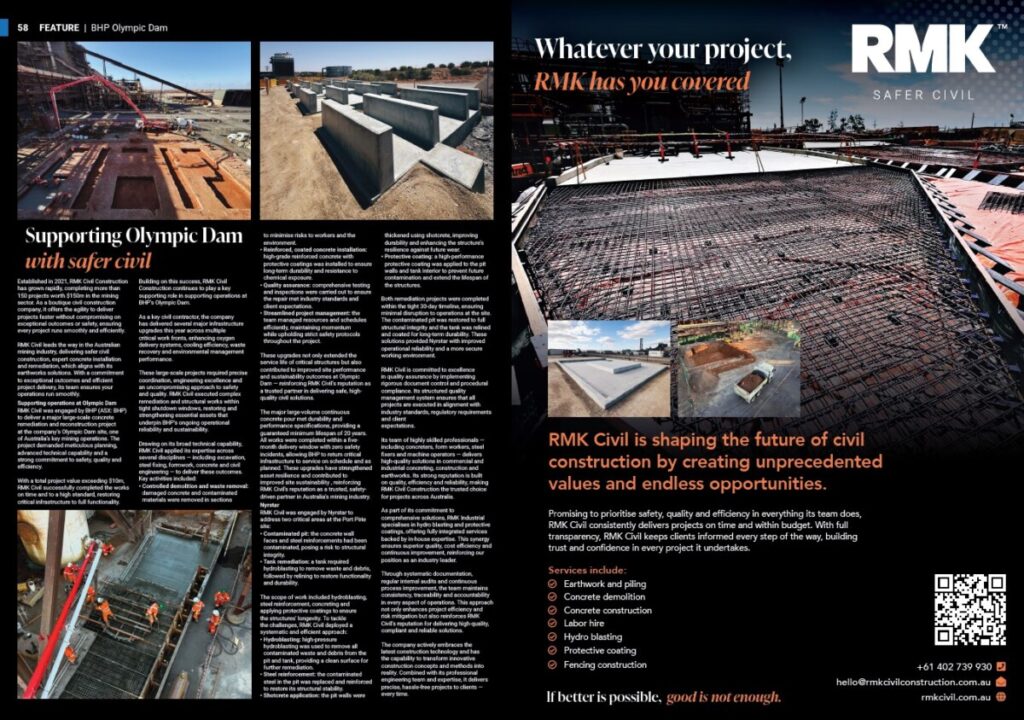

RMK Civil was engaged by BHP (ASX: BHP) to deliver a major large-scale concrete remediation and reconstruction project at the company’s Olympic Dam site, one of Australia’s key mining operations. The project demanded meticulous planning, advanced technical capability and a strong commitment to safety, quality and efficiency.

With a total project value exceeding $10m, RMK Civil successfully completed the works on time and to a high standard, restoring critical infrastructure to full functionality.

Building on this success, RMK Civil Construction continues to play a key supporting role in supporting operations at BHP’s Olympic Dam.

As a key civil contractor, the company has delivered several major infrastructure upgrades this year across multiple critical work fronts, enhancing oxygen delivery systems, cooling efficiency, waste recovery and environmental management performance.

These large-scale projects required precise coordination, engineering excellence and an uncompromising approach to safety and quality. RMK Civil executed complex remediation and structural works within tight shutdown windows, restoring and strengthening essential assets that underpin BHP’s ongoing operational reliability and sustainability.

Drawing on its broad technical capability, RMK Civil applied its expertise across several disciplines — including excavation, steel fixing, formwork, concrete and civil engineering — to deliver these outcomes. Key activities included:

- Controlled demolition and waste removal: damaged concrete and contaminated materials were removed in sections to minimise risks to workers and the environment.

- Reinforced, coated concrete installation: high-grade reinforced concrete with protective coatings was installed to ensure long-term durability and resistance to chemical exposure.

- Quality assurance: comprehensive testing and inspections were carried out to ensure the repair met industry standards and client expectations.

- Streamlined project management: the team managed resources and schedules efficiently, maintaining momentum while upholding strict safety protocols throughout the project.

These upgrades not only extended the service life of critical structures but also contributed to improved site performance and sustainability outcomes at Olympic Dam — reinforcing RMK Civil’s reputation as a trusted partner in delivering safe, high-quality civil solutions.

The major large-volume continuous concrete pour met durability and performance specifications, providing a guaranteed minimum lifespan of 20 years. All works were completed within a five-month delivery window with zero safety incidents, allowing BHP to return critical infrastructure to service on schedule and as planned. These upgrades have strengthened asset resilience and contributed to improved site sustainability , reinforcing RMK Civil’s reputation as a trusted, safety-driven partner in Australia’s mining industry.

Nyrstar

RMK Civil was engaged by Nyrstar to address two critical areas at the Port Pirie site:

- Contaminated pit: the concrete wall faces and steel reinforcements had been contaminated, posing a risk to structural integrity.

- Tank remediation: a tank required hydroblasting to remove waste and debris, followed by relining to restore functionality and durability.

The scope of work included hydroblasting, steel reinforcement, concreting and applying protective coatings to ensure the structures’ longevity. To tackle the challenges, RMK Civil deployed a systematic and efficient approach:

- Hydroblasting: high-pressure hydroblasting was used to remove all contaminated waste and debris from the pit and tank, providing a clean surface for further remediation.

- Steel reinforcement: the contaminated steel in the pit was replaced and reinforced to restore its structural stability.

- Shotcrete application: the pit walls were thickened using shotcrete, improving durability and enhancing the structure’s resilience against future wear.

- Protective coating: a high-performance protective coating was applied to the pit walls and tank interior to prevent future contamination and extend the lifespan of the structures.

Both remediation projects were completed within the tight 30-day timeline, ensuring minimal disruption to operations at the site. The contaminated pit was restored to full structural integrity and the tank was relined and coated for long-term durability. These solutions provided Nyrstar with improved operational reliability and a more secure working environment.

RMK Civil is committed to excellence in quality assurance by implementing rigorous document control and procedural compliance. Its structured quality management system ensures that all projects are executed in alignment with industry standards, regulatory requirements and client expectations.

Its team of highly skilled professionals — including concreters, form workers, steel fixers and machine operators — delivers high-quality solutions in commercial and industrial concreting, construction and earthworks. Its strong reputation is built on quality, efficiency and reliability, making RMK Civil Construction the trusted choice for projects across Australia.

As part of its commitment to comprehensive solutions, RMK Industrial specialises in hydro blasting and protective coatings, offering fully integrated services backed by in-house expertise. This synergy ensures superior quality, cost efficiency and continuous improvement, reinforcing our position as an industry leader.

Through systematic documentation, regular internal audits and continuous process improvement, the team maintains consistency, traceability and accountability in every aspect of operations. This approach not only enhances project efficiency and risk mitigation but also reinforces RMK Civil’s reputation for delivering high-quality, compliant and reliable solutions.

The company actively embraces the latest construction technology and has the capability to transform innovative construction concepts and methods into reality. Combined with its professional engineering team and expertise, it delivers precise, hassle-free projects to clients — every time.