Diesel Jetters Cut Costs

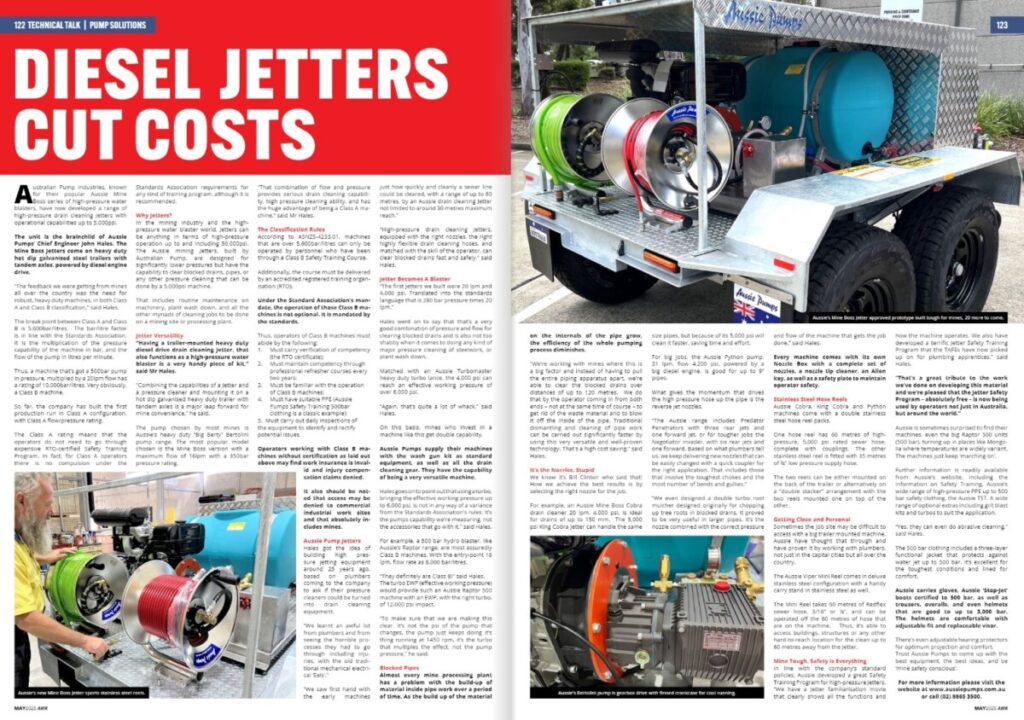

Australian Pump Industries, known for their popular Aussie Mine Boss series of high-pressure water blasters, have now developed a range of high-pressure drain cleaning Jetters with operational capabilities up to 5,000psi.

The brainchild of Aussie Pumps’ Chief Engineer John Hales the Mine Boss Jetters come on heavy duty hot dip galvanised steel trailers with tandem axles, powered by diesel engine drive.

“The feedback we were getting from mines all over the country was the need for robust, heavy duty machines, in both Class A and Class B classification,” said Mr Hales.

The break point between Class A and Class B is 5,600bar/litres. The bar/litre factor is in line with the Standards Association. It is the multiplication of the pressure capability of the machine in bar, and the flow of the pump in litres per minute.

Thus, a machine that’s got a 500bar pump in pressure, multiplied by a 20lpm flow has a rating of 10,000bar/litres. Very obviously, a Class B machine.

So far, the company has built the first production run in Class A configuration, with Class A flow/pressure rating.

The Class A rating means that the operators do not need to go through expensive RTO-certified Safety Training Programs. In fact, for Class A operators there is no compulsion under the Standards Association ratings for any kind of training program, although it is recommended.

Aussie’s training program for Class A machines is detailed below.

Why Jetters?

In the mining industry and the high-pressure water blaster world, Jetters can be anything in terms of high-pressure operation up to and including 50,000psi. The Aussie mining Jetters, built by Australian Pump, are designed for significantly lower pressures but have the capability to clear blocked drains, pipes, or any other pressure cleaning that can be done by a 5,000psi machine.

That includes routine maintenance on machinery, plant wash down, and all the other myriads of jobs to be done on a mining site or processing plant.

Jetter Versatility

“Having a trailer-mounted heavy duty diesel drive drain cleaning Jetter, that also functions as a high-pressure water blaster is a very handy piece of kit,” said Mr Hales.

“Combining the capabilities of a Jetter and a pressure cleaner and mounting it on a hot dip galvanised heavy duty trailer with tandem axles is a major leap forward for mine convenience,” he said.

The pump chosen by most mines is Aussie’s heavy duty “Big Berty” Bertolini pump range. The most popular model chosen is the Mine Boss version with a maximum flow of 16lpm with a 350bar pressure rating.

“That combination of flow and pressure provides serious drain cleaning capability, high pressure cleaning ability, and has the huge advantage of being a Class A machine,” said Mr Hales.

The Classification Rules

According to ASNZS-4233.01, machines that are over 5,600bar/litres can only be operated by personnel who have been through a Class B Safety Training Course.

Additionally, the course must be delivered by an accredited registered training organisation (RTO).

Under the Standard Association’s mandate, the operation of those Class B machines is not optional. It is mandated by the standards.

Thus, operators of Class B machines must abide by the following:

- Must carry verification of competency (the RTO certificate);

- Must maintain competency through professional refresher courses every two years;

- Must be familiar with the operation of Class B machines;

- Must have suitable PPE (Aussie Pumps Safety Training 500bar clothing is a classic example);

- Must carry out daily inspections of the equipment to identify and rectify potential issues.

Operators working with Class B machines without certification as laid out above may find work insurance is invalid and injury compensation claims denied.

It also should be noted that access may be denied to commercial industrial work sites and that absolutely includes mines.

Aussie Pump Jetters

Hales got the idea of building high pressure jetting equipment around 25 years ago, based on plumbers coming to the company to ask if their pressure cleaners could be turned into drain cleaning equipment.

“We learnt an awful lot from plumbers and from seeing the horrible processes they had to go through including injuries, with the old traditional mechanical electrical ‘Eels’.”

“We saw first hand with the early machines we built just how quickly and cleanly a sewer line could be cleared, with a range of up to 60 metres, by an Aussie drain cleaning Jetter as opposed to the old Eels that were limited to around 30 metres maximum reach.”

“We saw that high-pressure drain cleaning Jetters, equipped with the right nozzles, the right highly flexible drain cleaning hoses, and matched with the skill of the operator, can clear blocked drains fast and safely,” said Hales.

Jetter Becomes A Blaster

“The first Jetters we built were 20 lpm and 4,000 psi. Translated into the standards language that is 280 bar pressure times 20 lpm.”

Hales went on to say that that’s a very good combination of pressure and flow for clearing blocked drains and is also not too shabby when it comes to doing any kind of major pressure cleaning of steelwork, or plant wash down.

Matched with an Aussie Turbomaster heavy duty turbo lance, the 4,000 psi can reach an effective working pressure of over 6,000 psi.

“Again, that’s quite a lot of whack,” said Hales.

On this basis, mines who invest in a machine like this get double capability.

Aussie Pumps supply their machines with the wash gun kit as standard equipment, as well as all the drain cleaning gear. They have the capability of being a very versatile machine. In their new heavy duty tandem axle trailers, they are mobile as well.

Hales goes on to point out that using a turbo, bringing the effective working pressure up to 6,000 psi, is not in any kind of variance from the Standards Association’s rules. It’s the pumps capability we’re measuring, not the accessories that go with it,” said Hales.

For example, a 500 bar hydro blaster, like Aussie’s Raptor range, are most assuredly Class B machines, and with their capabilities of 500 bar are even with the entry-point 16 lpm, flow rate as 8,000 bar/litres.

“They definitely are Class B!” said Hales.

The turbo EWP (effective working pressure) would provide such an Aussie Raptor 500 machine with an EWP, with the right turbo, of 12,000 psi impact.

“Please make sure that we are making this clear. It’s not the psi of the pump that changes, the pump just keeps doing it’s thing running at 1450 rpm, it’s the turbo that multiples the effect, not the pump pressure,” he said.

Blocked Pipes

Almost every mine processing plant has a problem with the build-up of material inside the pipe over a period of time. As the build up of the material on the internals of the pipe grow, the efficiency of the whole pumping process diminishes.

“We’re working with mines where this is a big factor and instead of having to pull the entire piping apparatus apart, we’re able to clear the blocked drains over distances of up to 120 metres. We do that by the operator coming in from both ends – not at the same time of course – to get rid of the waste material and to blow it off the inside of the pipe. Thousands of dollars of traditional dismantling and cleaning of pipe work can be carried out significantly faster by using this very versatile and well-proven technology,” said Hales.

It’s the Nozzles, Stupid

We know it’s Bill Clinton and the economy! How we achieve the best results is by selecting the right nozzle for the job.

For example, an Aussie Mine Boss Cobra drain cleaner 20 lpm, 4,000 psi, is ideal for drains of up to 150 mm. The 5,000 psi King Cobra Jetter can handle the same size pipes, but because of its 5,000 psi will clean it faster, saving time and effort.

For big jobs, the Aussie Python pump, 31 lpm, 4,200 psi, powered by a big diesel engine, is good for up to 9” pipes.

What gives the momentum that drives the high pressure hose up the pipe is of course the reverse jet nozzles.

“The Aussie range includes Predator penetrators with three rear jets and one forward jet, or for tougher jobs the Negotiator Invader, with six rear jets and one forward. Based on what plumbers tell us, we keep delivering new nozzles that can be easily changed with a quick coupler for the right application, including those that involve the toughest chokes and the most number of bends and gullies.”

“We even designed a double turbo root mulcher designed originally for chopping up tree roots in blocked drains. It proved to be very useful in larger pipes. It’s the nozzle combined with the correct pressure and flow of the machine that gets the job done,” said Hales.

Every machine comes with its own nozzle box with a complete set of nozzles, a nozzle tip cleaner, an Allen key, as well as a safety plate to cover blocked drains, maintaining operator safety.

Stainless Steel Hose Reels

Aussie Cobra, King Cobra and Python machines come with a double stainless steel hose reel packs.

One hose reel has 60 metres of high-pressure, 5,000 psi rated sewer hose, complete with couplings. Whilst the other stainless steel reel is fitted with 35 metres of ¾” low pressure supply hose.

The two reels can be either mounted on the back of the trailer or alternatively on a “double stacker” arrangement with the two reels mounted one on top of the other.

Getting Close and Personal

Sometimes the job site may be difficult to access with a big trailer mounted machine. Aussie have thought that through and have proven it by working with plumbers, not just in the capital cities but all over the country.

The Aussie Viper Mini Reel comes in deluxe stainless steel configuration with the reel itself, and the handy carry stand being in stainless steel as well.

The Mini Reel takes 60 metres of Redflex sewer hose, 3/16” or ¼”, and can be operated off the 60 metres of hose that are on the machine. Thus, it’s able to access buildings, structures or any other hard-to-reach location for the clean out up to 60 metres away from the Jetter.

Mine Tough, Safety is Everything

In line with the company’s standard policies, Aussie developed a great Safety Training Program for high-pressure Jetters.

“We have a Jetter familiarisation movie that clearly shows all the functions and how the machine operates. We also have developed a terrific Jetter Safety Training Program that the TAFEs have now picked up on for plumbing apprentices,” said Hales.

“That’s a great tribute to the work we’ve done on developing this material and we’re pleased that the Jetter Safety Program – absolutely free – is now being used by operators not just in Australia, but around the world.”

Aussie is sometimes surprised to find their machines, even the big Raptor 500 units (500 bar), turning up in places like Mongolia where temperatures are widely variant, and yet the machines just keep ‘marching on’.

Further information is readily available from Aussie’s website, including the information on Safety Training, Aussie’s wide range of high-pressure PPE up to 500 bar safety clothing, the Aussie TST, a wide range of optional extras including grit blast kits and turbos to suit the machines.

“Yes, they can even do abrasive cleaning,” said Hales.

The 500 bar clothing includes a three-layer functional jacket that protects against water jet up to 500 bar. It’s excellent for the toughest conditions and lined for high comfort.

Aussie carries gloves, Aussie ‘Stop-Jet’ boots certified to 500 bar, as well as trousers, overalls, and even helmets that are good to up to 3,000 bar. The helmets are comfortable with adjustable fit and replaceable visor.

There’s even adjustable hearing protectors for optimum projection and comfort.

Trust Aussie Pumps to come up with the best equipment, the best ideas, and be ‘mine safety conscious’.

For more information please visit the website at www.aussiepumps.com.au or call (02) 8865 3500.