A new dawn for Ensham mine

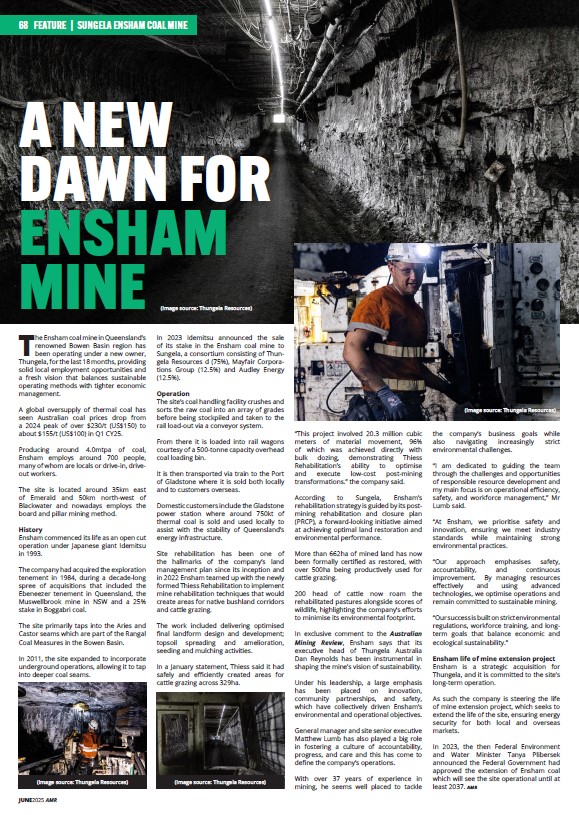

The Ensham coal mine in Queensland’s renowned Bowen Basin region has been operating under a new owner, Thungela, for the last 18 months, providing solid local employment opportunities and a fresh vision that balances sustainable operating methods with tighter economic management.

A global oversupply of thermal coal has seen Australian coal prices drop from a 2024 peak of over $230/t (US$150) to about $155/t (US$100) in Q1 CY25.

Producing around 4.0mtpa of coal, Ensham employs around 700 people, many of whom are locals or drive-in, drive-out workers.

The site is located around 35km east of Emerald and 50km north-west of Blackwater and nowadays employs the board and pillar mining method.

History

Ensham commenced its life as an open cut operation under Japanese giant Idemitsu in 1993.

The company had acquired the exploration tenement in 1984, during a decade-long spree of acquisitions that included the Ebeneezer tenement in Queensland, the Muswellbrook mine in NSW and a 25% stake in Boggabri coal.

The site primarily taps into the Aries and Castor seams which are part of the Rangal Coal Measures in the Bowen Basin.

In 2011, the site expanded to incorporate underground operations, allowing it to tap into deeper coal seams.

In 2023 Idemitsu announced the sale of its stake in the Ensham coal mine to Sungela, a consortium consisting of Thungela Resources d (75%), Mayfair Corporations Group (12.5%) and Audley Energy (12.5%).

Operation

The site’s coal handling facility crushes and sorts the raw coal into an array of grades before being stockpiled and taken to the rail load-out via a conveyor system.

From there it is loaded into rail wagons courtesy of a 500-tonne capacity overhead coal loading bin.

It is then transported via train to the Port of Gladstone where it is sold both locally and to customers overseas.

Domestic customers include the Gladstone power station where around 750kt of thermal coal is sold and used locally to assist with the stability of Queensland’s energy infrastructure.

Site rehabilitation has been one of the hallmarks of the company’s land management plan since its inception and in 2022 Ensham teamed up with the newly formed Thiess Rehabilitation to implement mine rehabilitation techniques that would create areas for native bushland corridors and cattle grazing.

The work included delivering optimised final landform design and development; topsoil spreading and amelioration, seeding and mulching activities.

In a January statement, Thiess said it had safely and efficiently created areas for cattle grazing across 329ha.

“This project involved 20.3 million cubic meters of material movement, 96% of which was achieved directly with bulk dozing, demonstrating Thiess Rehabilitation’s ability to optimise and execute low-cost post-mining transformations.” the company said.

According to Sungela, Ensham’s rehabilitation strategy is guided by its post-mining rehabilitation and closure plan (PRCP), a forward-looking initiative aimed at achieving optimal land restoration and environmental performance.

More than 662ha of mined land has now been formally certified as restored, with over 500ha being productively used for cattle grazing.

200 head of cattle now roam the rehabilitated pastures alongside scores of wildlife, highlighting the company’s efforts to minimise its environmental footprint.

In exclusive comment to the Australian Mining Review, Ensham says that its executive head of Thungela Australia Dan Reynolds has been instrumental in shaping the mine’s vision of sustainability.

Under his leadership, a large emphasis has been placed on innovation, community partnerships, and safety, which have collectively driven Ensham’s environmental and operational objectives.

General manager and site senior executive Matthew Lumb has also played a big role in fostering a culture of accountability, progress, and care and this has come to define the company’s operations.

With over 37 years of experience in mining, he seems well placed to tackle the company’s business goals while also navigating increasingly strict environmental challenges.

“I am dedicated to guiding the team through the challenges and opportunities of responsible resource development and my main focus is on operational efficiency, safety, and workforce management,” Mr Lumb said.

“At Ensham, we prioritise safety and innovation, ensuring we meet industry standards while maintaining strong environmental practices.

“Our approach emphasises safety, accountability, and continuous improvement. By managing resources effectively and using advanced technologies, we optimise operations and remain committed to sustainable mining.

“Our success is built on strict environmental regulations, workforce training, and long-term goals that balance economic and ecological sustainability.”

Ensham life of mine extension project

Ensham is a strategic acquisition for Thungela, and it is committed to the site’s long-term operation.

As such the company is steering the life of mine extension project, which seeks to extend the life of the site, ensuring energy security for both local and overseas markets.

In 2023, the then Federal Environment and Water Minister Tanya Plibersek announced the Federal Government had approved the extension of Ensham coal which will see the site operational until at least 2037.