World-proven shotcrete technology, tailored for Australian conditions

Putzmeister is a globally recognised leader in concrete and shotcrete technology, with a long-standing reputation for delivering robust, high-performance equipment to some of the world’s most demanding underground and tunnelling projects. Through its dedicated underground division, Putzmeister Underground, the company has pioneered innovations in robotic shotcrete application, concrete transport and quality control, supporting major mining operations across Europe, the Americas and Asia.

In Australia, Putzmeister is building on this global legacy. The business has earned a strong reputation for delivering reliable concrete placement solutions, particularly through its range of truck-mounted concrete pumps and placing systems used in major infrastructure projects nationwide. The company is now extending that capability into the mining sector.

Momentum is building in the underground space, with Putzmeister Oceania steadily expanding its footprint in mining. A growing pipeline of opportunities, combined with proven global technology and a commitment to local support, positions the business as a strong and reliable partner for shotcrete and concrete equipment solutions across Australia and New Zealand.

Global tech with a local touch

Putzmeister’s shotcrete equipment has been tested in some of the world’s most demanding underground and mining projects. So whilst the brand is relatively new to the Australian mining market, it is backed by decades of global experience and innovation.

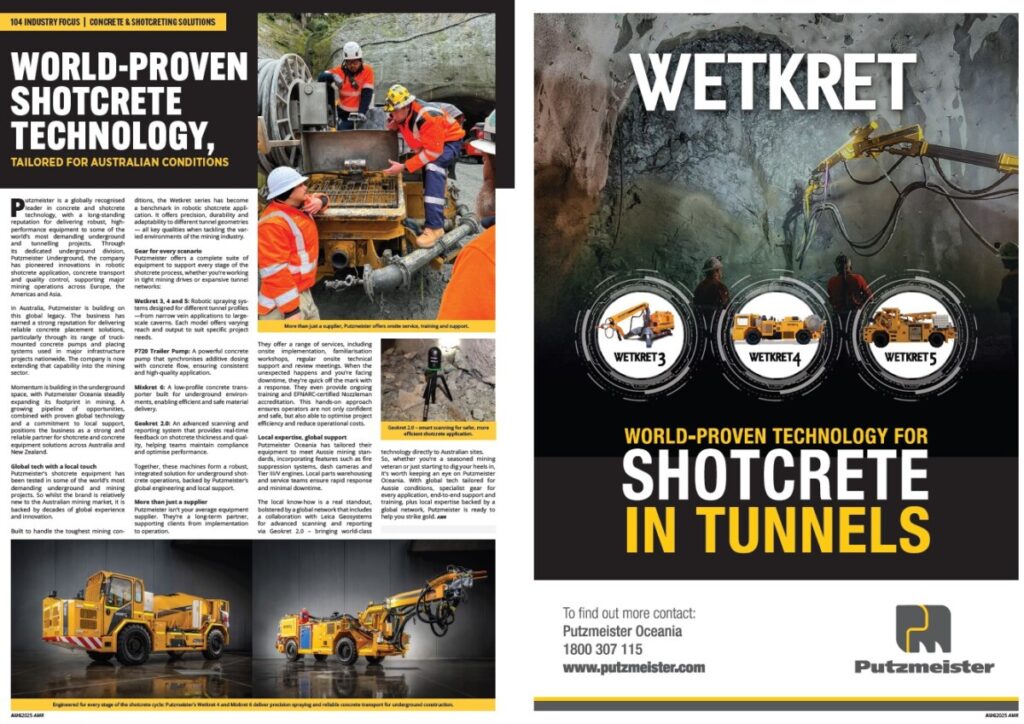

Built to handle the toughest mining conditions, the Wetkret serieshas become a benchmark in robotic shotcrete application. It offers precision, durability and adaptability to different tunnel geometries — all key qualities when tackling the varied environments of the mining industry.

Gear for every scenario

Putzmeister offers a complete suite of equipment to support every stage of the shotcrete process, whether you’re working in tight mining drives or expansive tunnel networks:

Wetkret 3, 4 and 5: Robotic spraying systems designed for different tunnel profiles —from narrow vein applications to large-scale caverns. Each model offers varying reach and output to suit specific project needs.

P720 Trailer Pump: A powerful concrete pump that synchronises additive dosing with concrete flow, ensuring consistent and high-quality application.

Mixkret 6: A low-profile concrete transporter built for underground environments, enabling efficient and safe material delivery.

Geokret 2.0: An advanced scanning and reporting system that provides real-time feedback on shotcrete thickness and quality, helping teams maintain compliance and optimise performance.

Together, these machines form a robust, integrated solution for underground shotcrete operations, backed by Putzmeister’s global engineering and local support.

More than just a supplier

Putzmeister isn’t your average equipment supplier. They’re a long-term partner, supporting clients from implementation to operation.

They offer a range of services, including onsite implementation, familiarisation workshops, regular onsite technical support and review meetings. When the unexpected happens and you’re facing downtime, they’re quick off the mark with a response. They even provide ongoing training and EFNARC-certified Nozzleman accreditation. This hands-on approach ensures operators are not only confident and safe, but also able to optimise project efficiency and reduce operational costs.

Local expertise, global support

Putzmeister Oceania has tailored their equipment to meet Aussie mining standards, incorporating features such as fire suppression systems, dash cameras and Tier III/V engines. Local parts warehousing and service teams ensure rapid response and minimal downtime.

The local know-how is a real standout, bolstered by a global network that includes a collaboration with Leica Geosystems for advanced scanning and reporting via Geokret 2.0 – bringing world-class technology directly to Australian sites.

So, whether you’re a seasoned mining veteran or just starting to dig your heels in, it’s worth keeping an eye on Putzmeister Oceania. With global tech tailored for Aussie conditions, specialist gear for every application, end-to-end support and training, plus local expertise backed by a global network, Putzmeister is ready to help you strike gold.