Next generation i-ALERT3 takes machine monitoring to new levels

Production and maintenance personnel are rostered around the clock to ensure plant equipment availability is maximised and running as smooth as possible while faced with the constant threat of costly downtime. Critical components must therefore be constantly monitored to prevent any potential issues where unplanned repairs will result in a complete or partial plant shutdown.

Not only are machine components subject to wear and tear, abrasion, impact, dust, corrosion, humidity, and high temperatures, but there’s also the inherent health and safety risks that personnel face as they perform their day-to-day tasks.

This is why intuitive condition monitoring is such an integral part of any reliable industrial operation. The ability to diagnose and eliminate faults before they happen, subsequently improving operational performance, can’t be overstated.

An obvious, yet technologically sophisticated solution is machine performance monitoring. With more than 170 years of building reliable and innovative pumps, the ITT range of monitoring and control systems are designed for the mining, oil and gas, chemical, power generation, and biopharmaceutical industries.

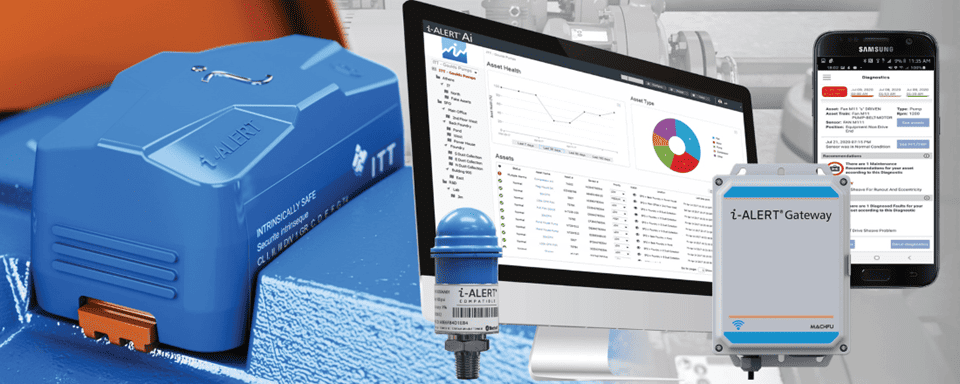

The new i-ALERT3 wireless condition monitoring is a unique product that exemplifies ITT’s commitment to innovation in the industrial space.

Decades of experience and R&D in monitoring and rotating equipment technology, are packaged into the i-ALERT. This has led to the development of an accurate, flexible, scalable and easy-to-use machine health system.

The i-ALERT identifies issues and diagnoses mechanical and electrical failures in pumps, motors, and other industrial machines, before they occur – And, it does it faster, more accurately and cost-effectively, while enabling proactive intervention, reducing production outage and lost revenue.

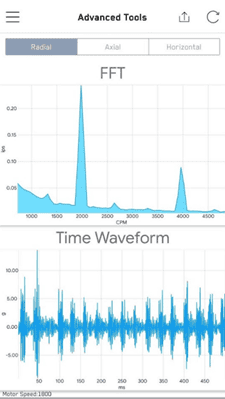

The availability of automated, real-time diagnostics via a free mobile app, or Ai platform, prove a real value add alongside auto full-spectrum FFT and time wave-form vibration analysis.

Approved for use in IECEx Hazardous areas, which creates an even safer environment for operators, i-ALERT has a broad range of applications including pumps, fans, mixers, motors, gearboxes, and structural studies. Plant operators can integrate data with Control Room available, and can detect stage 2 bearing defects before failure.

ITT principal reliability engineer Omar Grand explained how the new technology is not only making machine performance monitoring easier than ever, but what makes the technology different to anything else on the market.

“Our new solution is ultimately designed to improve machine protection, optimise plant reliability, and reduce downtime,” said Grand.

“The sensor uses a wider vibration frequency range for more efficient issue detection, and also features a field-replaceable battery, which minimises replacement time and cost.” said Grand.

“The i-ALERT is an advanced remote condition monitoring solution that provides real-time insights into equipment health and performance. This is achieved through the combination of wireless sensors, data analytics, and cloud-based software that enable proactive maintenance and optimise asset reliability.”

Grand said that the i-ALERT features Bluetooth communication for easy set-up via the i-ALERT Mobile App, as well as expanded 24/7 capabilities through the i-ALERT Gateway and Ai Platform. “This enables users to track the performance of all their machines fitted with i-ALERT sensors in a single, convenient place, remotely from anywhere.”

Other notable features of the new system include robust wireless software updates that seamlessly add new features and enhance existing ones. Additionally, a new magnetic flux sensor that includes electrical health analysis capabilities for motors, accurate run speed and load trending, and faster wireless data speeds using the latest Bluetooth technology (BLE 5.0) reduces data download times with the Mobile App.

“Compared to other remote monitoring systems, i-ALERT offers a number of unique features that make it the trusted maintenance tool industrial and mining companies have come to expect,” added Grand.

For more information on how i-ALERT works, watch the video, call +61 8 9302 1855, or visit https://www.i-alert.com/