Tanami: Newmont’s Tier 1 titan

In February 2024, Newmont (ASX: NEM) announced its intention to divest its non-core assets, including six operations and two projects from its Australian, Ghanaian and North American business units. Throughout the year, Newmont executed this strategy, shedding non-core assets to concentrate solely on its Tier 1 assets.

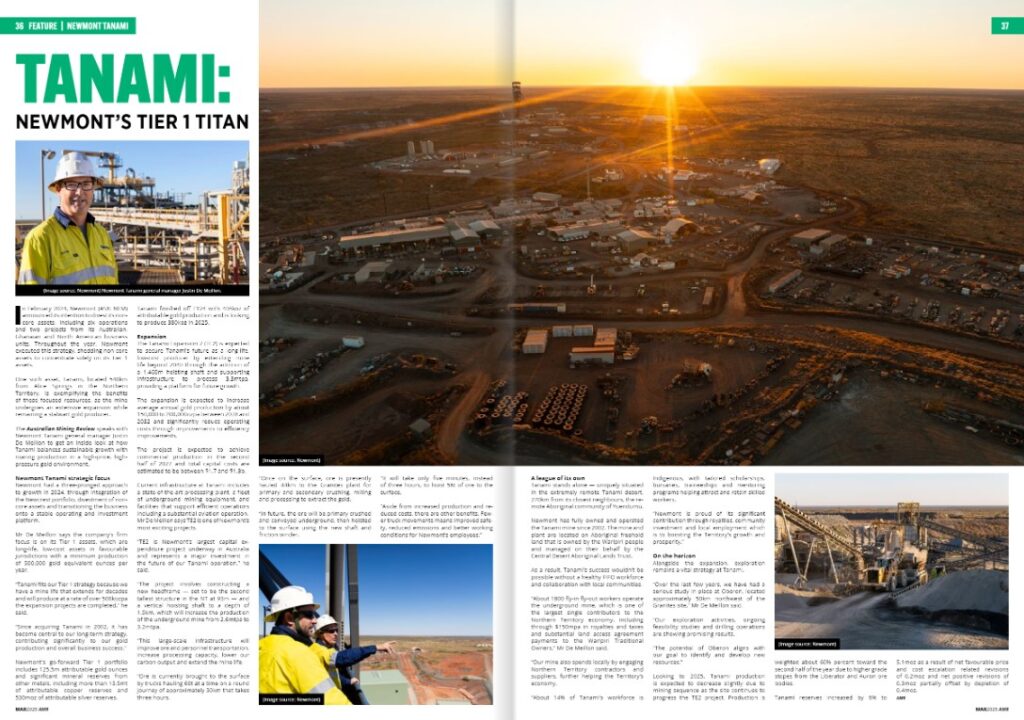

One such asset, Tanami, located 540km from Alice Springs in the Northern Territory, is exemplifying the benefits of these focused resources, as the mine undergoes an extensive expansion while remaining a stalwart gold producer.

The Australian Mining Review speaks with Newmont Tanami general manager Justin De Meillon to get an inside look at how Tanami balances sustainable growth with roaring production in a high-price, high-pressure gold environment.

Newmont Tanami strategic focus

Newmont had a three-pronged approach to growth in 2024, through integration of the Newcrest portfolio, divestment of non-core assets and transitioning the business onto a stable operating and investment platform.

Mr De Meillon says the company’s firm focus is on its Tier 1 assets, which are long-life, low-cost assets in favourable jurisdictions with a minimum production of 500,000 gold equivalent ounces per year.

“Tanami fits our Tier 1 strategy because we have a mine life that extends for decades and will produce at a rate of over 500kozpa the expansion projects are completed,” he said.

“Since acquiring Tanami in 2002, it has become central to our long-term strategy, contributing significantly to our gold production and overall business success.”

Newmont’s go-forward Tier 1 portfolio includes 125.5m attributable gold ounces and significant mineral reserves from other metals, including more than 13.5mt of attributable copper reserves and 530moz of attributable silver reserves.

Tanami finished off FY24 with 408koz of attributable gold production and is looking to produce 380koz in 2025.

Expansion

The Tanami Expansion 2 (TE2) is expected to secure Tanami’s future as a long-life, low-cost producer by extending mine life beyond 2040 through the addition of a 1,460m hoisting shaft and supporting infrastructure to process 3.3mtpa, providing a platform for future growth.

The expansion is expected to increase average annual gold production by about 150,000 to 200,000ozpa between 2028 and 2032 and significantly reduce operating costs through improvements to efficiency improvements.

The project is expected to achieve commercial production in the second half of 2027 and total capital costs are estimated to be between $1.7 and $1.8b.

Current infrastructure at Tanami includes a state-of-the-art processing plant, a fleet of underground mining equipment, and facilities that support efficient operations including a substantial aviation operation.

Mr De Meillon says TE2 is one of Newmont’s most exciting projects.

“TE2 is Newmont’s largest capital expenditure project underway in Australia and represents a major investment in the future of our Tanami operation,” he said.

“The project involves constructing a new headframe — set to be the second tallest structure in the NT at 93m — and a vertical hoisting shaft to a depth of 1.5km, which will increase the production of the underground mine from 2.6mtpa to 3.2mtpa.

“This large-scale infrastructure will improve ore and personnel transportation, increase processing capacity, lower our carbon output and extend the mine life.

“Ore is currently brought to the surface by trucks hauling 60t at a time on a round journey of approximately 30km that takes three hours.

“Once on the surface, ore is presently hauled 44km to the Granites plant for primary and secondary crushing, milling and processing to extract the gold.

“In future, the ore will be primary crushed and conveyed underground, then hoisted to the surface using the new shaft and friction winder.

“It will take only five minutes, instead of three hours, to hoist 56t of ore to the surface.

“Aside from increased production and reduced costs, there are other benefits. Fewer truck movements means improved safety, reduced emissions and better working conditions for Newmont’s employees.”

A league of its own

Tanami stands alone — uniquely situated in the extremely remote Tanami desert, 270km from its closest neighbours, the remote Aboriginal community of Yuendumu.

Newmont has fully owned and operated the Tanami mine since 2002. The mine and plant are located on Aboriginal freehold land that is owned by the Warlpiri people and managed on their behalf by the Central Desert Aboriginal Lands Trust.

As a result, Tanami’s success wouldn’t be possible without a healthy FIFO workforce and collaboration with local communities.

“About 1800 fly-in fly-out workers operate the underground mine, which is one of the largest single contributors to the Northern Territory economy, including through $150mpa in royalties and taxes and substantial land access agreement payments to the Warlpiri Traditional Owners,” Mr De Meillon said.

“Our mine also spends locally by engaging Northern Territory contractors and suppliers, further helping the Territory’s economy.

“About 14% of Tanami’s workforce is Indigenous, with tailored scholarships, bursaries, traineeships and mentoring programs helping attract and retain skilled workers.

“Newmont is proud of its significant contribution through royalties, community investment and local employment which is to boosting the Territory’s growth and prosperity.”

On the horizon

Alongside the expansion, exploration remains a vital strategy at Tanami.

“Over the last few years, we have had a serious study in place at Oberon, located approximately 50km northwest of the Granites site,” Mr De Meillon said.

“Our exploration activities, ongoing feasibility studies and drilling operations are showing promising results.

“The potential of Oberon aligns with our goal to identify and develop new resources.”

Looking to 2025, Tanami production is expected to decrease slightly due to mining sequence as the site continues to progress the TE2 project. Production is weighted about 60% percent toward the second half of the year due to higher grade stopes from the Liberator and Auron ore bodies.

Tanami reserves increased by 6% to 5.1moz as a result of net favourable price and cost escalation related revisions of 0.2moz and net positive revisions of 0.3moz partially offset by depletion of 0.4moz.