Flood rescue: Aussie gears up

The recent floods in central and northern Queensland are a clear indication that climate change is a reality and, we need to be geared to deal with these crises. The devastation created by the floods has led Aussie Pumps to increase their production of their big 6” heavy duty trash pumps.

Powered by 80 hp Deutz air cooled diesel engine, these pumps are built in Aussie’s factory warehouse complex in Sydney’s Norwest Business District.

“These are the same pumps that have consistently saved the capital city of South Sudan from seasonal flooding over the last 3-4 years”, said Aussie Pumps Chief Engineer, John Hales.

Those big 6” pumps, sometimes air freighted to South Sudan, have done a mighty job in what can only be described as trying circumstances.

Saving South Sudan

Australian Pump, working with the United Nations, was called upon to provide sufficient capacity to divert the Nile River around the city of Juba, saving it from flooding. The first request came in 2022. The company moved into high gear to produce the 6,000lpm pumps for urgent air freight to Africa.

“That was a very expensive exercise in terms of freight but had a major impact on reducing the threat to Juba. The pumps were able to move up to 1,000,000 litres per hour,” said Hales.

Why Aussie Pumps?

Hales explains, “it was about the ability to pump huge amounts of water, potentially contaminated with overflowing sewage and debris, of all types. The feedback we got from the people on site was that they had tried wet prime pumps using compressors or vacuum pumps for priming with poor results. Our wet prime pumps are designed for high volume trash handling applications that are required in mine sites or flood situations like South Sudan.”

Aussie says there are major reasons why big volume self primers are more reliable and certainly more productive for flood mitigation, whether saving towns or dewatering mines.

“It’s the same application,” said Hales. “Our big Aussie self primers are the solution every time.”

Why self priming?

Aussie’s self priming pump range starts with 2” models and go up to 3”, 4” and 6” configurations.

“3” spherical solids are no problem for these pumps. They will handle dirty water and even contaminated sewage without any issues,” said Hales.

The Aussie approach is that self priming is simple. There are so few parts to go wrong, no fancy valves or springs to clog, just a huge high SG cast iron impeller operating in a gigantic cast pump body with an inbuilt priming tank. It’s that priming tank that enables these pumps to lift contaminated water through a suction of 7.6 metres vertical lift.

Priming is easy. It’s just three simple actions. 1, undo the priming cap built into the top of the pump and fill the pump body with water. 2, make sure the coupling on the suction side where the hose is, is completely airtight so no air can penetrate. 3, start the engine and the pump starts pumping.

Its simplicity means less moving parts. All there is, is the impeller, spinning at the speed of the engine rpm and the check valve built into the suction port that enables the pump to produce the vacuum that makes the suction lift so efficient. That seal is a unique oil lubricated tungsten titanium carbide configuration.

“We found mechanical seals operating on mine sites on a continuous basis last and last. Operators can easily check the oil level in the seal to make sure it is properly lubricated, even in the toughest environment,” said Hales.

Why trash pumps?

Heavy duty trash pumps like the Aussie range can handle solids in suspension without damage. Their designs all include a front mounted clean out port that enables chokes to be cleared in a matter of minutes. In other words, it’s purpose-designed for pumping abrasive and solid laden liquids.

Deutz power

The big pump is powered by an 80 hp air cooled Deutz diesel engine with built in protection. The pump/motor combo itself is mounted on a robust steel frame, incorporating a 150L fuel tank. That tank allows the engine an 11-hour run time.

The frame comes with an integrated balanced lift bar. Safety equipment includes a Lofa engine control shutdown system, which incorporates warnings for low oil pressure, high oil temperature and even v-belt failure. A shock mounted control panel is also provided. It’s built into a water-resistant housing and includes an hour-meter, ammeter, tachometer and alternator failure light.

“It’s designed to be simple, virtually unbreakable and easy to access,” said Hales.

Mobile too

The Aussie engineers have enabled the skid mount version to be capable of being turned into a heavy-duty site trailer configuration as well. That site trailer is built tough for the worst conditions you can imagine. It includes a robust torsion style dual axle, with a maximum load of 1,600kg.

A heavy-duty army style drawbar and pintle is standard equipment. Robust jack legs are also incorporated in the trailer for additional stability.

Saving Horsham

It was almost 20 years now since Millers Contracting, an earthmoving contractor in Victoria, used an Aussie MQ600TD 6,000lpm pump, purchased for dewatering, to save the Victorian town of Horsham from flooding.

The Millers team moved fast when the floods hit and were able to pump water from the town into a side channel, providing “instant flood relief service.”

More recently the same model has been acquired by earthmoving contractors, for major roadworks, fast filling water carts and flood mitigation applications. It really is a great civil engineering aid.

Proven performers

Aussie’s big 6” pump action is not confined to Australia and Africa. “Our pumps are doing a great job in Indonesia and PNG. In fact, when Tonga flooded in 2022, the Tongan Government took two of these big trash pumps to save the island from serious flood damage. Those pumps did a mighty job,” said Hales.

Aussie likes self priming pumps because they’re simple. They know designing components out of the system is a great way to reduce maintenance and complications. The less parts there are, the less there is to go wrong.

Aussie’s Mine Boss

The company is a specialist when it comes to self priming centrifugal pump equipment. Although they started out making lightweight portable trash pumps in the 90s, the product range today includes machines specifically designed for mining applications.

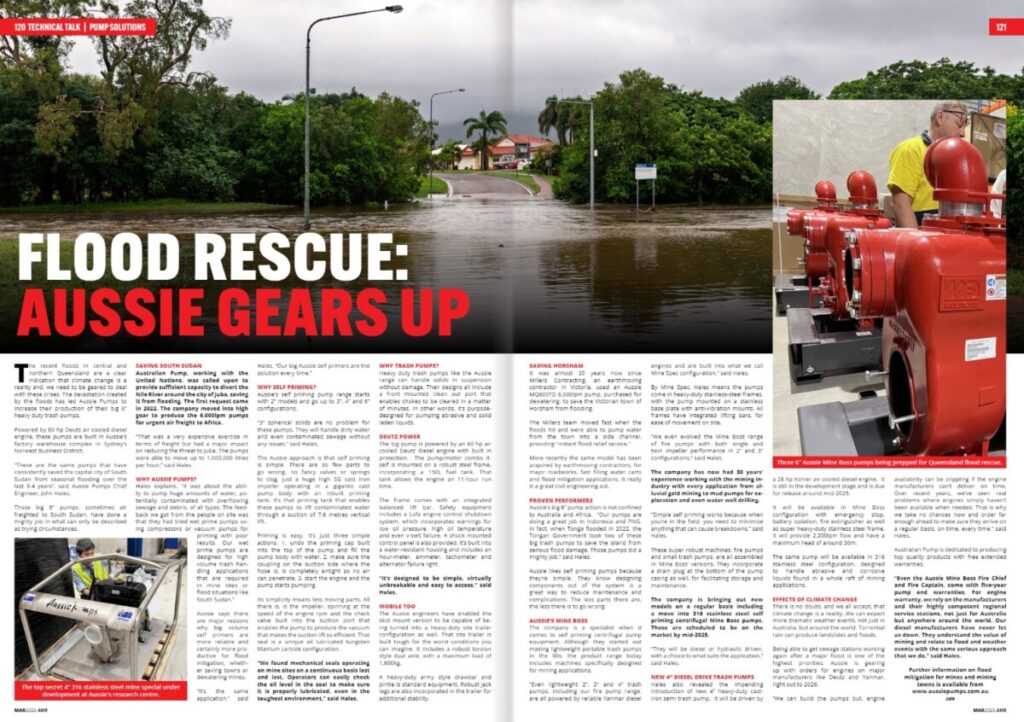

“Even lightweight 2”, 3” and 4” trash pumps, including our fire pump range, are all powered by reliable Yanmar diesel engines and are built into what we call Mine Spec configuration,” said Hales.

By Mine Spec, Hales means the pumps come in heavy-duty stainless-steel frames, with the pump mounted on a stainless base plate with anti-vibration mounts. All frames have integrated lifting bars, for ease of movement on site.

“We even evolved the Mine Boss range of fire pumps with both single and twin impeller performance in 2” and 3” configurations,” said Hales.

The company has now had 30 years’ experience working with the mining industry with every application from alluvial gold mining to mud pumps for exploration and even water well drilling.

“Simple self priming works because when you’re in the field, you need to minimise anything that can cause breakdowns,” said Hales.

These super robust machines, fire pumps and small trash pumps, are all assembled in ‘Mine Boss’ versions. They incorporate a drain plug at the bottom of the pump casing as well, for facilitating storage and maintenance.

The company is bringing out new models on a regular basis including a move into 316 stainless steel self priming centrifugal Mine Boss pumps. These are scheduled to be on the market by mid-2025.

“They will be diesel or hydraulic driven, with a choice to what suits the application,” said Hales.

New 4” diesel drive trash pumps

Hales also revealed the impending introduction of new 4” heavy-duty cast-iron semi trash pump. It will be driven by a 26 hp Kohler air cooled diesel engine. It is still in the development stage and is due for release around mid-2025.

It will be available in Mine Boss configuration with emergency stop, battery isolation, fire extinguisher as well as super heavy-duty stainless steel frame. It will provide 2,200lpm flow and have a maximum head of around 30m.

The same pump will be available in 316 stainless steel configuration, designed to handle abrasive and corrosive liquids found in a whole raft of mining applications.

Effects of climate change

There is no doubt, and we all accept, that climate change is a reality. We can expect more dramatic weather events, not just in Australia, but around the world. Torrential rain can produce landslides and floods.

Being able to get sewage stations working again after a major flood is one of the highest priorities. Aussie is gearing up with orders for engines on major manufacturers like Deutz and Yanmar, right out to 2026.

“We can build the pumps but, engine availability can be crippling if the engine manufacturers can’t deliver on time. Over recent years, we’ve seen real problems where engines simply haven’t been available when needed. That is why we take no chances now and order far enough ahead to make sure they arrive on a regular basis, on time, every time,” said Hales.

Australian Pump is dedicated to producing top quality products with free extended warranties.

“Even the Aussie Mine Boss Fire Chief and Fire Captain, come with five-year pump end warranties. For engine warranty, we rely on the manufacturers and their highly competent regional service stations, not just for Australia but anywhere around the world. Our diesel manufacturers have never let us down. They understand the value of mining and relate to flood and weather events with the same serious approach that we do,” said Hales.

Further information on flood mitigation for mines and mining towns is available from aussiepumps.com.au