Keep your crew cool

Industrial ice makers and dispensers

Heat stress is a significant problem in Australian mining, where extreme weather can compromise workers’ well-being and performance. Having access to ice is a simple and effective solution to help remedy the situation. As we know adding ice to water not only makes it more refreshing on hot days, but it also boosts consumption, resulting in improved hydration and avoidance of heat stress.

Providing ice for your teams is more than a courtesy, it’s a welfare measure to be taken seriously. Standalone ice makers placed in high-traffic areas such as kitchens, mess halls, water stations and first aid shelters can be a morale and comfort builder for crews. At distant camps with complex logistics and questionable supply lines, on-site ice production is an operational convenience in everyday use.

Ice also makes cold storage feasible in circumstances where refrigeration on its own isn’t sufficient. Ice stores food and perishables safely, especially where cold chain transport is not easily accessible.

Cubed ice is particularly easy to access in large-volume kitchens for big crews to keep meals and beverages cold and fresh.

Aside from hydration and protection of food, ice also has a use during emergency situations. Ice can be used in first-aid responses to reduce swelling, create cooling packs or alleviate overheating during prolonged operations.

Having the ice dispensed via a chute mechanism also provides a hygienic option to ensure that contamination of the ice is minimised, both during storage as well as during dispensing into water jugs and drinking bottles.

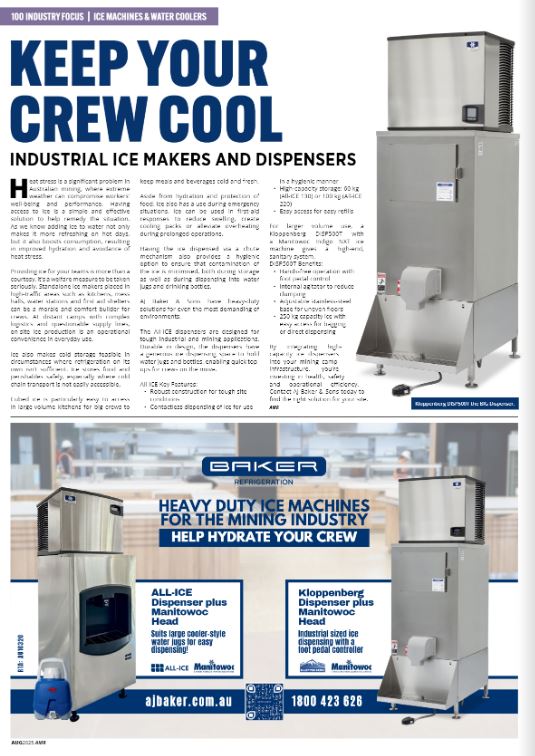

AJ Baker & Sons have heavy-duty solutions for even the most demanding of environments.

The All-ICE dispensers are designed for tough industrial and mining applications. Durable in design, the dispensers have a generous ice dispensing space to hold water jugs and bottles, enabling quick top-ups for crews on the move.

All-ICE Key Features:

- Robust construction for tough site conditions

- Contactless dispensing of ice for use in a hygienic manner

- High-capacity storage: 60 kg (All-ICE 130) or 100 kg (All-ICE 220)

- Easy access for easy refills

For larger volume use, a Kloppenberg DISP500T with a Manitowoc Indigo NXT ice machine gives a high-end, sanitary system.

DISP500T Benefits:

- Hands-free operation with foot pedal control

- Internal agitator to reduce clumping

- Adjustable stainless-steel base for uneven floors

- 250 kg capacity ice with easy access for bagging or direct dispensing

By integrating high-capacity ice dispensers into your mining camp infrastructure, you’re investing in health, safety and operational efficiency. Contact AJ Baker & Sons today to find the right solution for your site.