Broons: the crushing and compaction specialist

An unrestricted supply chain is the lifeline of every remote mining operation. Equipment, fuel, labour and materials are as critical on the way in as the movement of the mineral resource on the way out. Little wonder there’s an increasing focus on the maintenance of often lengthy gravel access roads at remote sites.

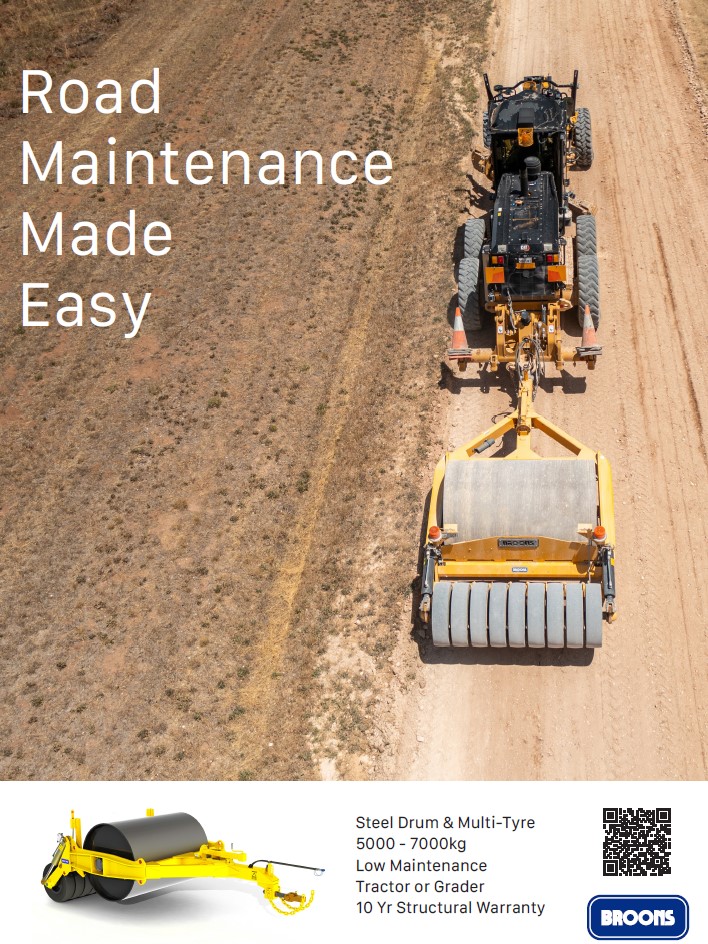

Broons has the answer. Their range of towed compaction rollers have been the industry standard for well over 50 years and remain widely used in the construction and maintenance of gravel roads across the nation.

Their industry leading 10-year structural warranty is without equal, such is the confidence they have in their products. Suitability, durability and reliability are hallmarks of a Broons roller. An Australian company to the core, Broons’ locally designed and built rollers have been shaped by our harsh environment and all its challenges.

The most versatile in their towed fleet is the eCombi — or “economical combination” roller. The smooth steel roll drum provides heavy hitting compaction to be sure you’ve built the strongest pavement whilst the rear mounted multi-tyre configuration rounds off the process for a smooth hard finish.

With a tare weight close to 6t, Broons’ eCombi grows to around 8t by adding water ballast in the roll drum enabling you to put down a road that’ll actually stay down.

Hydraulically raised and lowered from the cab, the 14-ply smooth tread compactor tyres are solid filled to avoid costly delays from punctures and eliminating risk. Every feature on the eCombi roller is designed for maximum productivity and to minimise maintenance. With no complicated electronics or hydraulics, operators remain and their cab, safe and sound at all times.

Towed by either tractor or grader, via a jaw hitch or Ringfeder, the eCombi can be easily adapted as different plant becomes available. Combined with a grader it’s the ultimate in equipment efficiency. Just one operator can rip, spread and compact a gravel road. That’s maximum distance to the dollar for a single wage and tank of fuel.

With around 20 different options available, Broons will customise an eCombi roller to suit your individual needs. Call the team at Broons to discuss a trial.

Find out more: www.broons.com | info@broons.com | (08) 8268 1988