Dartbrook hits the bullseye

After 18 years in care and maintenance, the Dartbrook underground coal mine —located in the iconic Hunter Valley region of NSW — has seen a flurry of activity across the course of the last twelve months and is now set to ramp up production, under new owner Australian Pacific Coal (ASX: AQC) and its joint venture partner Tetra Resources.

First opened in 1995 Dartbrook underground employs the bord and pillar mining method and was previously owned by Anglo Coal Australia. After humming along for over a decade, falling coal prices and operational problems saw it shuttered in 2006.

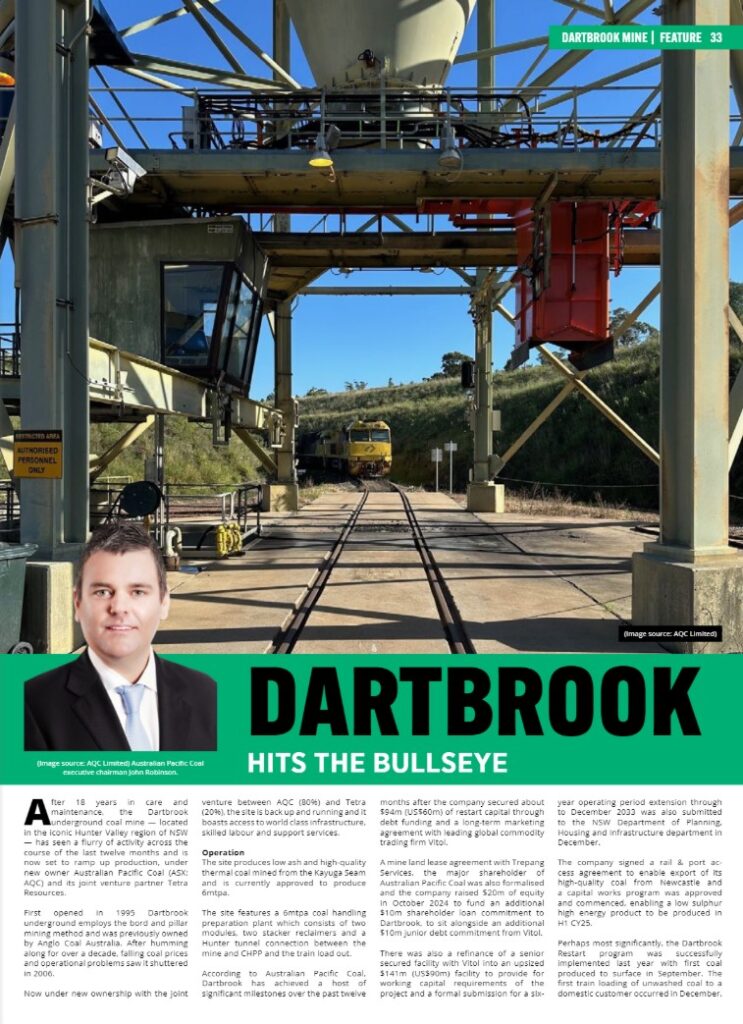

Now under new ownership with the joint venture between AQC (80%) and Tetra (20%), the site is back up and running and it boasts access to world class infrastructure, skilled labour and support services.

Operation

The site produces low ash and high-quality thermal coal mined from the Kayuga Seam and is currently approved to produce 6mtpa.

The site features a 6mtpa coal handling preparation plant which consists of two modules, two stacker reclaimers and a Hunter tunnel connection between the mine and CHPP and the train load out.

According to Australian Pacific Coal, Dartbrook has achieved a host of significant milestones over the past twelve months after the company secured about $94m (US$60m) of restart capital through debt funding and a long-term marketing agreement with leading global commodity trading firm Vitol.

A mine land lease agreement with Trepang Services, the major shareholder of Australian Pacific Coal was also formalised and the company raised $20m of equity in October 2024 to fund an additional $10m shareholder loan commitment to Dartbrook, to sit alongside an additional $10m junior debt commitment from Vitol.

There was also a refinance of a senior secured facility with Vitol into an upsized $141m (US$90m) facility to provide for working capital requirements of the project and a formal submission for a six-year operating period extension through to December 2033 was also submitted to the NSW Department of Planning, Housing and Infrastructure department in December.

The company signed a rail & port access agreement to enable export of its high-quality coal from Newcastle and a capital works program was approved and commenced, enabling a low sulphur high energy product to be produced in H1 CY25.

Perhaps most significantly, the Dartbrook Restart program was successfully implemented last year with first coal produced to surface in September. The first train loading of unwashed coal to a domestic customer occurred in December.

Speaking exclusively to the Australian Mining Review, Australian Pacific Coal executive chairman John Robinson praised the company’s diligence in the way it managed the Dartbrook restart program and remains confident in the demand for the product particularly in Asia.

“The transition from an asset in care and maintenance for almost 18 years, through to recommissioning production at the Dartbrook underground mine in September 2024 was a major milestone for the AQC, its stakeholders and partner Tetra Resources,” he said.

“Both AQC and its JV partner Tetra Resources have demonstrated high levels of safety and economic discipline through-out the recommissioning of Dartbrook in September 24. This is evidenced by the on-time on budget capital program delivering production of coal at Dartbrook.

“Dartbrook is well positioned in the NSW Hunter Valley, with existing access through to world class export facilities in Newcastle. Dartbrook is also unique in that it has historically produced high energy, low sulphur coal that is highly sought after by Asian high energy low emissions power utilities. Ongoing studies are being conducted to investigate the potential to produce semi soft/PCI coal.”

As an underground mine, the Dartbrook joint venture has a significantly low surface footprint resulting in less than 5% of the surface disturbance relative to the size of its mining leases, significantly less than neighbouring mines in the Hunter Valley region.

The site continues to ramp up production levels, with additional mining units being commissioned and the further onboarding of staff, with about 150 full-time personnel currently working at the site and a total of 200 as the operation continues.

Future forecasts

With Dartbrook underground situated in an agricultural region, APC says the company is committed to operating harmoniously with surface pastoral landowners and cattle grazing operations and noise reduction strategies have been implemented such as speed reduction of surface conveyors at the CHPP and train load out.

Continued emphasis on operational standards has led to improved horizon control seam selection and floor conditions in the underground mine.

Reducing roadway widths underground has also increased cutting efficiencies.

Production levels at the site are expected to increase this year as additional underground mining systems are procured and commissioned. The mine plan is targeting having four continuous mining units in operation within the first 12–18 months of production.

A recruitment drive is also underway to attract quality mining operators to the Dartbrook project and a work program to refurbish the wash plant has commenced with commissioning anticipated in the H1 CY25 which will enable production of high-quality Newcastle spec coal at attractive prices.