Pioneers of Fluid Intelligence

Fuel management is a primary factor affecting bottom line performance across the resources sector. Disjointed fluid management compromises operational efficiency, safety and environmental sustainability.

A comprehensive system that combines fuel management hardware and software is essential to increasing accuracy, accountability, security and productivity from expensive fluids.

Empowering clients across the global resources sector with innovative fluid resource management solutions — Banlaw are the pioneers of fluid intelligence.

Trusted by industry partners, including Fortescue (ASX: FMG), BHP (ASX: BHP), Rio Tinto (ASX: RIO) and Glencore, Banlaw promises to improve economic, environmental and safety performance. Banlaw provides smart, reliable and safe resource management solutions for fuel, oil, hydrogen, ammonia and other fluid assets.

The company operates out of its headquarters located in the Hunter Valley in NSW, considered by many to be the centre of Australia’s industrial heartland. Trusted by many, Banlaw’s systems can be found throughout Australia and across the globe where it has created an international ecosystem of distributors, repairers, technology partners and operations.

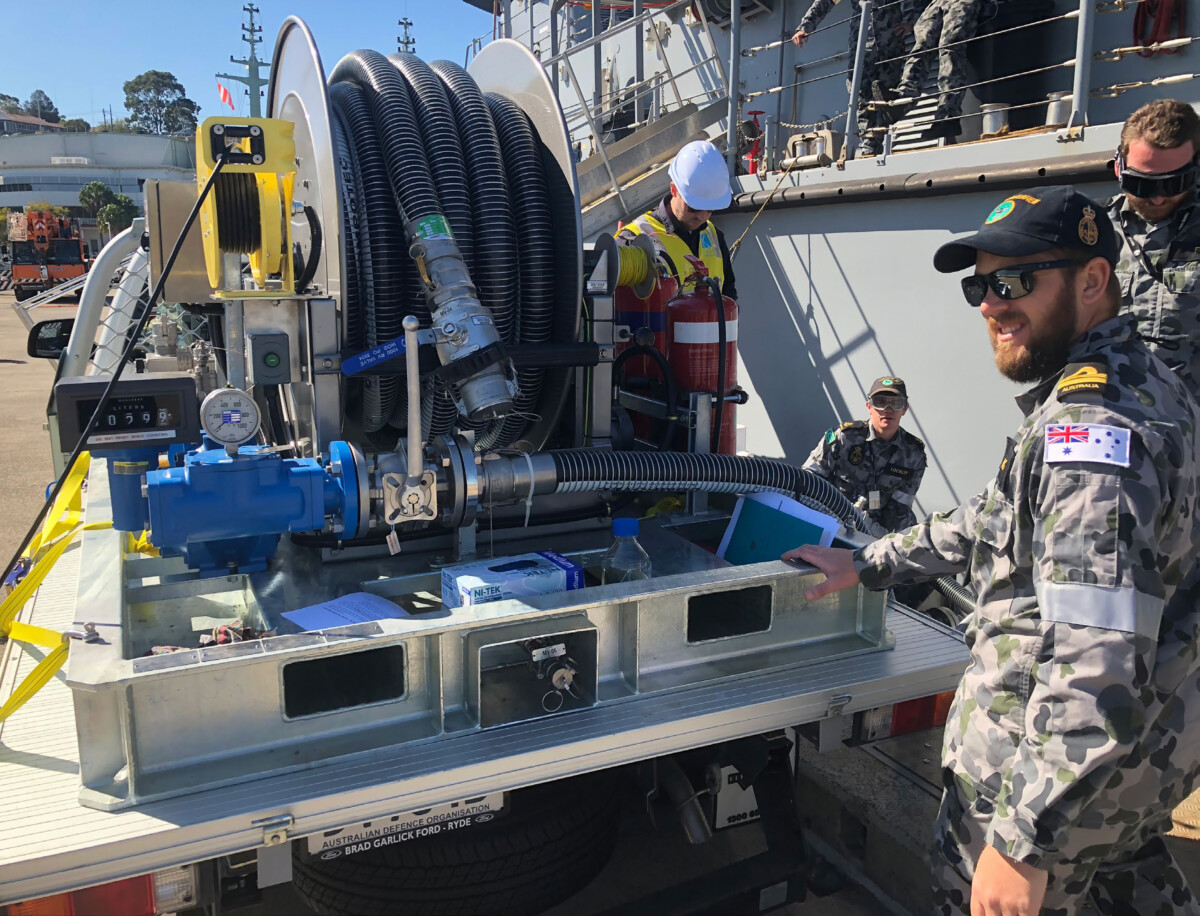

Banlaw sets the standard for fluid management solutions across the global mining, infrastructure, agriculture, marine, rail and heavy industries. The company’s products are found at numerous world-class mining operations as well as on farms, depots, ports and construction sites — all industries where fluid management is critical.

The Banlaw ecosystem

Banlaw is leading the fluid management game with its innovative and tailored technologies, offering the world’s only end-to-end fuel management system (FMS).

A complete fuel management solution is not a standalone interface — it is a critical system of components that work in harmony to enable security and data integrity whilst saving both time and money.

ResTrack Resource Management Software (RMS) is a comprehensive management software solution that unlocks value throughout the delivery, storage and dispensing phases of managing high-value fluids.

ResTrack RMS coordinates all access, storage and movement of liquids — giving users complete control over their high-value fluids. This allows users to access complete and accurate data of every litre that has been dispensed on a per-machine basis.

The comprehensive data allows consumers to only pay for the fluids they receive, eliminate fuel theft and rapidly identify leakage due to equipment degradation.

The visibility and accountability that comes from a modern fluid asset management solution creates savings and performance improvements you can bank on. It yields completely replicable outcomes, helps develop a culture of productivity and limits business risk and exposure to unplanned outages.

ResTrack RMS automates previously manual processes for operators and includes secure access controlled by on-site hardware with integrated and unobtrusive technologies. These data automations reduce opportunities for human error and consequent costs.

The precision and control that comes from integrating automation into your fluid management system reaps unparalleled control and efficiency to operations.

Real-world success

Banlaw fuel management systems currently manage in-excess of 1bL of fuel every month for consumers across 33 countries — saving users millions of dollars.

With rapid expansion and fuel burn exceeding millions of litres per month, Fortescue identified that maintenance and security of its assets was disjointed and unreliable. Banlaw has unified fuel supply for Fortescue by providing management solutions to maintain the company’s fuel infrastructure across its operations. This has delivered Fortescue fuel security, major cost savings and confidence in the integrity of the system and data provided.

Following the partnership, Fortescue reported fuel accountability of 99.68% by volume. This validated the synergistic benefit of using Banlaw’s system, which is now being used across Fortescue’s operations.

Banlaw continues to expand its exporting capabilities and deepen client partnerships across the globe. The company’s growth and excellence were recognised with the HunterNet Award for Export Excellence earlier this year. This showcased Banlaw’s commitment to innovation, quality and the global reach of its Australian-made technologies.

As the company extends its reach, it welcomes new and exciting partners and projects. Banlaw’s extensive range of integrated systems, products and services put operators back in control of their fluid management and cost savings.

With more than 40 years of industry experience, Banlaw can provide solutions tailored to the budget and physical scale of any project’s needs.