Solar-powered, relocatable boom gates

The next evolution in mine site access.

Secure access solutions are critical to operations, but it has been a challenge for mining companies to find a reliable provider — until now.

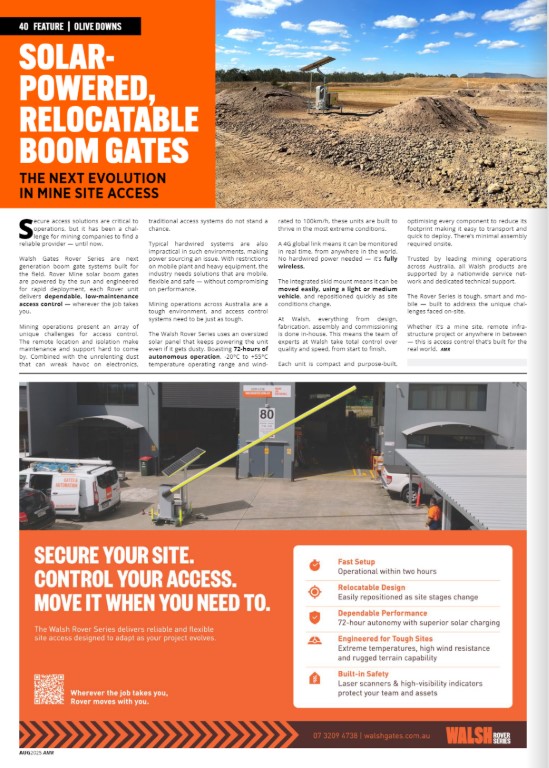

Walsh Gates Rover Series are next generation boom gate systems built for the field. Rover Mine solar boom gates are powered by the sun and engineered for rapid deployment, each Rover unit delivers dependable, low-maintenance access control — wherever the job takes you.

Mining operations present an array of unique challenges for access control. The remote location and isolation make maintenance and support hard to come by. Combined with the unrelenting dust that can wreak havoc on electronics, traditional access systems do not stand a chance.

Typical hardwired systems are also impractical in such environments, making power sourcing an issue. With restrictions on mobile plant and heavy equipment, the industry needs solutions that are mobile, flexible and safe — without compromising on performance.

Mining operations across Australia present tough conditions, and access control systems need to be just as tough.

The Walsh Rover Series uses an oversized solar panel that keeps powering the unit even if it gets dusty. Boasting 72-hours of autonomous operation, -20°C to +55°C temperature operating range and wind-rated to 100km/h, these units are built to thrive in the most extreme conditions.

A 4G global link means it can be monitored in real time, from anywhere in the world. No hardwired power needed — it’s fully wireless.

The integrated skid mount means it can be moved easily, using a light or medium vehicle, and repositioned quickly as site conditions change.

At Walsh, everything from design, fabrication, assembly and commissioning is done in-house. This means the team of experts at Walsh take total control over quality and speed, from start to finish.

Each unit is compact and purpose-built, optimising every component to reduce its footprint making it easy to transport and quick to deploy. There’s minimal assembly required onsite.

Trusted by leading mining operations across Australia, all Walsh products are supported by a nationwide service network and dedicated technical support.

The Rover Series is tough, smart and mobile — built to address the unique challenges faced on-site.

Whether it’s a mine site, remote infrastructure project or anywhere in between — this is access control that’s built for the real world.