BHP on track for 2050 net-zero target

BHP (ASX: BHP) reports it is on track to reach its 2030 decarbonisation target, with net-zero operations expected by 2050.

BHP expects a 30% reduction in operational greenhouse gas (GHG) emissions by 2030 and has already reduced FY2023 emissions by 30% below the FY2020 baseline.

BHP plans to reach its targets through decarbonisation efforts in mining operations and steelmaking and shipping value chains.

BHP climate vice president Graham Winkelman says emissions reduction may not be linear.

“As we grow to meet increasing demand for our commodities, the pathway to net zero for our operational emissions will not be a straight line,” he said.

“Our pathway reflects the dynamic nature of the assets we operate and the availability and readiness of decarbonisation solutions.”

Operations

Mr Winkelman says focussing on diesel replacement is key to reducing operational emissions.

“Our current GHG emissions profile is weighted towards diesel and has been for a couple of years now,” he said.

“While technology solutions for diesel displacement are emerging, many are not yet mature and available at the scale required.”

“If technology develops as we believe it can, we expect the first electric truck fleet adoption by FY2028, and in FY2030, the first of multiple future electric locomotive deployments.”

BHP operational decarbonisation vice president Dan Heal says connecting the Pilbara region of WA to renewable energy sources is also necessary to achieve BHP’s targets.

“Our inland Pilbara operations are not connected to an existing grid and so we cannot purchase power through the market,” he said.

“Renewable technologies such as wind and solar are available, but the Pilbara is remote, so we are working through the best way to introduce large volumes of renewable energy, or other sources of low to zero emissions power while keeping power running 24/7, 365 days a year.

“By the end of this decade, we plan to have up to 500MW of wind, solar and battery storage assets available in the Pilbara, backed up by firm power from our highly efficient Yarnima gas fired power station.”

Steelmaking

BHP has found it challenging to decarbonise its steelmaking operations, as there are currently no feasible near zero emissions technologies for widespread adoption.

BHP decarbonisation and partnerships head Dr Nigel Tame says supporting industry to develop the necessary technologies is key to decarbonising steelmaking.

“Our strategic approach involves establishing initiatives, including partnerships and consortiums, with our customers, research, and venture capital investments to advance the readiness of steel decarbonisation technologies,” he said.

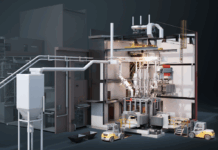

BHP has identified modified blast furnace (BF) and direct reduce iron (DRI), electric smelting furnace (ESF) and electric arc furnace (EAF) technologies as key processing routes.

“For the BF, we believe that emissions reduction options can be combined to achieve, and well exceed, the 30% emissions intensity reduction capability of our CY2030 goal, and head towards near zero,” Dr Tame said.

“The pairing of DRI with an ESF has deep emissions intensity reduction potential – around 80% relative to the conventional blast furnace route today.”

Shipping

BHP maritime safety, sustainability and technical head Ashima Taneja says pursuing future fuels development will decarbonise their shipping value chain.

“We were the first to charter a dual-fuelled LNG Newcastlemax vessel in CY2022 and now have five

operating in our iron ore trade route,” she said.

“We were a first-mover in conducting trials of biofuels on an ocean-going vessel and have now operationalised biofuel lifts – that is the process of refuelling a vessel – on select voyages in our supply chain.

“In trials utilising biofuels, we have been able to achieve emissions abatement ranging from 19-22% on a well-to-wake basis when compared to emissions from using similar quantities of conventional fuels.

“Our actions, together with actions in the wider industry, led us to achieve a total GHG emissions intensity reduction in BHP-chartered shipping of our products of 41% in FY2023 from a CY2008 baseline.”