Historic goldfield — modern innovation

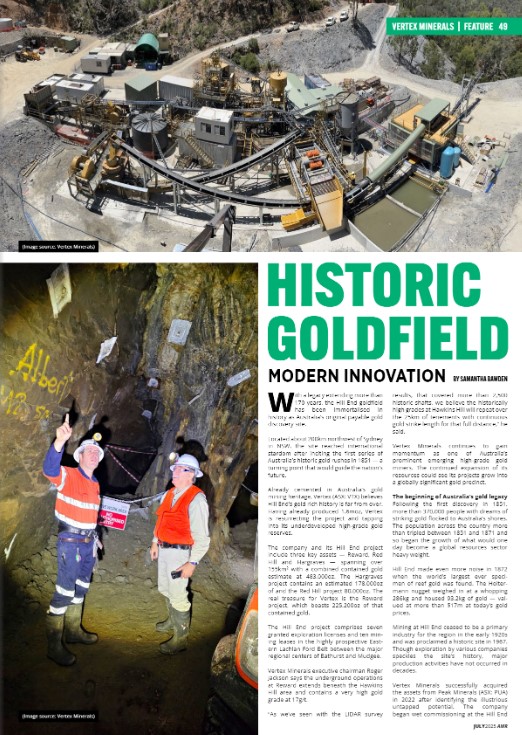

With a legacy extending more than 170 years, the Hill End goldfield has been immortalised in history as Australia’s original payable gold discovery site.

Located about 200km northwest of Sydney in NSW, the site reached international stardom after inciting the first series of Australia’s historic gold rushes in 1851 — a turning point that would guide the nation’s future.

Already cemented in Australia’s gold mining heritage, Vertex (ASX: VTX) believes Hill End’s gold rich history is far from over. Having already produced 1.6moz, Vertex is resurrecting the project and tapping into its underdeveloped high-grade gold reserves.

The company and its Hill End project include three key assets — Reward, Red Hill and Hargraves — spanning over 155km2 with a combined contained gold estimate at 483,000oz. The Hargraves project contains an estimated 178,000oz of and the Red Hill project 80,000oz. The real treasure for Vertex is the Reward project, which boasts 225,200oz of that contained gold.

The Hill End project comprises seven granted exploration licenses and ten mining leases in the highly prospective Eastern Lachlan Ford Belt between the major regional centers of Bathurst and Mudgee.

Vertex Minerals executive chairman Roger Jackson says the underground operations at Reward extends beneath the Hawkins Hill area and contains a very high gold grade at 17g/t.

“As we’ve seen with the LIDAR survey results, that covered more than 2,500 historic shafts, we believe the historically high grades at Hawkins Hill will repeat over the 25km of tenements with continuous gold strike length for that full distance,” he said.

Vertex Minerals continues to gain momentum as one of Australia’s prominent emerging high-grade gold miners. The continued expansion of its resources could see its projects grow into a globally significant gold precinct.

The beginning of Australia’s gold legacy

Following the first discovery in 1851, more than 370,000 people with dreams of striking gold flocked to Australia’s shores. The population across the country more than tripled between 1851 and 1871 and so began the growth of what would one day become a global resources sector heavy weight.

Hill End made even more noise in 1872 when the world’s largest ever specimen of reef gold was found. The Holtermann nugget weighed in at a whopping 286kg and housed 93.2kg of gold — valued at more than $17m at today’s gold prices.

Mining at Hill End ceased to be a primary industry for the region in the early 1920s and was proclaimed a historic site in 1967. Though exploration by various companies speckles the site’s history, major production activities have not occurred in decades.

Vertex Minerals successfully acquired the assets from Peak Minerals (ASX: PUA) in 2022 after identifying the illustrious untapped potential. The company began wet commissioning at the Hill End processing plant the following year using existing stockpiles.

Reward is currently undergoing developmental works on site with Vertex’s jumbo underground drill. This includes extension and safety improvement works of the underground shaft. Primary ventilation and airlines have been installed and are operational. First stope development dewatering has been completed and water feed has been installed.

Full time underground mining operations are expected to commence in the coming weeks and will provide feed for the on-site processing facility.

Old technology, modern applications

Extraction methods and processing techniques vastly impact the profitability, viability and sustainability of projects. Reward’s rare geology means that Vertex can leverage old school methods to achieve enhanced extraction rates with incredible cost efficiency and low environmental impact.

The geology of the project includes significant gold mineralisation associated with quartz veins, a feature which makes the ore amenable to gravity separation techniques. This is a significant advantage for the company as no chemicals are required to liberate the gold and high recovery can be achieved using low energy inputs.

The recently commissioned Gekko gold gravity processing plant has revolutionised operational efficiency at Reward. The refurbished plant has the capacity to treat up to 120ktpa — a significant upgrade to the previous 30ktpa plant.

Not only does it have a lower demand for water, power and four times the production capacity, it reduces operating costs by only requiring two on-site operators.

“This small but high-tech plant utilises advanced ore sorting and gravity methods to process high-grade gold without the use of chemicals or a large ball mill,” Mr Jackson said.

“It is clearly an upgrade in size, complexity and technology and offers a very low environmental footprint.”

Underground ore was trialled through the gravity plant in early June and throughput exceeded expectation beyond the nameplate plant flow sheet value.

The new mine schedule for the Reward underground site proposes mining two stop blocks consisting of 2,705t at 17.8g/t of gold and 700t at 42.5g/t of gold.

Gravity green gold

Not only is Vertex reviving the long-neglected site, but it is also building a mine with a smaller environmental footprint than any existing operations in Australia, according to the company.

The unique processing attributes of the ore at Reward promotes the concept of low impact production, aptly referred to as ‘gravity green gold’. This method leverages the high density of gold in a process that is cost-effective and achieves recovery rates more than 90% all while being more ecologically aware than traditional extraction processes.

Gravity separation is a mechanical process that sees the ore crushed and then put through a sorter, where waste rock is separated from the gold bearing quartz. The material is then spun in a centrifuge before being run over a wet, oscillating table to further separate it. The remaining gold then needs to be simply melted down.

The gravity approach requires no harsh chemicals, like cyanide, arsenic, mercury and lead, that are used in considerable amounts in the traditional gold extraction process.

“We are fortunate enough to have gravity-recoverable gold, all we need is the power of water and gravity,” Mr Jackson said.

“The water can be reused and recycled and the tails remaining can be safely stored as a sand pile, meaning we do not need a tailings dam.”

The continued underground development at the site ensures there is very little disturbance of the surface, aligning with growing industry concern towards environmental responsibility.

By breathing new life into Australia’s most historic gold project, Vertex is establishing itself as a significant player in Australia’s gold rich industry.

Vertex continues to expand its operations across Australia with tenements across WA including its Taylor Rock project in the far southeastern region of the Archaean Lake Johnston greenstone belt.

The company also is undergoing exploration at its Pride of Elvire project that covers a 51km2 area in the Mt Elvire greenstone belt of WA. The site has seen historic small-scale gold mining from the last century, with Broken Hill Metals conducting exploration in the area from the mid to late 1980s.

The success of operations at Hill End is fostering curiosity amongst many industry players and, with a great number of decommissioned sites spotting the country, unlocking the potential to revive legacy mines.