Purpose designed agitator and mixer drives

Engineering companies and original equipment manufacturers (OEMs) have long leaned on the “bigger is better” approach when it comes to choosing gearboxes for mixing applications. While it’s been a safe bet, this method often leads to unnecessarily large, underused gear units.

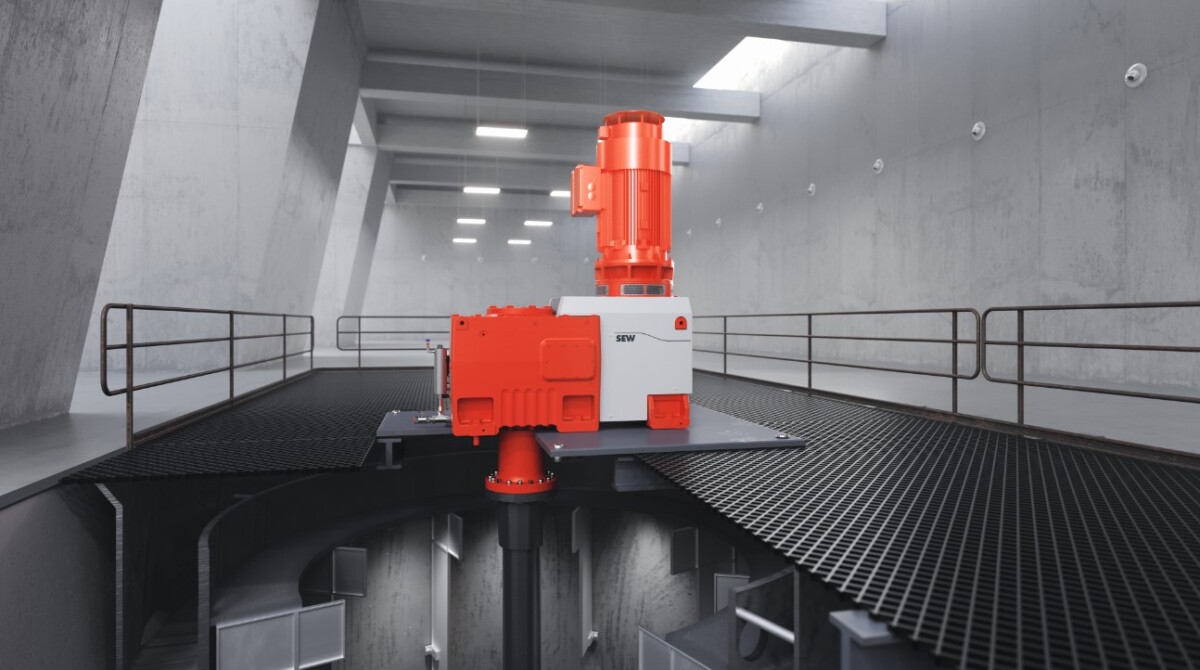

Now, there’s a new solution on the horizon from SEW-EURODRIVE — the X.e Agitator and Mixer Drive.

What sets this beauty apart from your run-of-the-mill gearboxes is the unique design. The X.e Agitator and Mixer Drive separates the high-speed gear train from the low-speed output shaft, making it possible to deal with challenging rotating overhung loads with minimal deflection. This clever setup accommodates larger output shafts and bearings, ensuring top performance, even in the toughest agitating and mixing tasks.

SEW-EURODRIVE didn’t just whip this up out of thin air. They’ve used modern finite element method (FEM) software to make sure the housing integrity of this new drive is up to scratch. Plus, they’ve put it through its paces with real-life simulations on the only load test rig for gearboxes in the world that can apply defined rotating overhung loads.

Two steps to the right drive

Choosing the right drive with SEW-EURODRIVE is as easy as 1, 2.

First, the torque is determined using a service factor from the catalogue. A service factor of 1.5 or more ensures the gear will last forever under designed loads without any deflections caused by external loads.

Second, the overhung loads are determined. Every mixer or agitator is different — their radial loads, bending moments, thrusts and peaks can be all over the shop. The size of the low-speed shaft and the bearing arrangement are picked based on these unique factors, maximising shaft safety against fatigue and making sure the desired bearing life is met.

The X.e Agitator and Mixer Drive also boasts optimised airflow for fan cooling, which cuts down on the need for external coolers. It features a drywell design that keeps oil in the sump to stop leaks, multiple shaft and bearing arrangements for added flexibility and a split line above the oil level to stop leaks from the gearbox split-line gasket.

Other noteworthy features include a fully draining sump for 100% drainage, an internal pump to increase reliability by protecting against leaks, immediate oil delivery after the first start-up, easy maintenance access and integrated filter and instruments.

10 reasons why

- Optimised airflow for fan cooling: external coolers are seldomly required.

- Drywell: a riser tube over the low speed shaft traps the oil in the sump

eliminating any risk of leaking.

- Multiple shaft and bearing arrangements: optimised shaft strength and bearing life without over or under sizing any components.

- Split line above oil level: makes it physically impossible for oil to leak out of the gearbox split-line gasket.

- Fully draining Sump: typically, universal housings have pockets that will never drain, contaminating new oil after an oil change. The X.e/HM mixer housing drains 100%, eliminating contamination of new oil.

- Internal Pump: protects the pump from the elements and eliminates the risk of an oil leak, improving reliability.

- Immediate Oil Delivery: unlike traditional pressure lubricated systems that

require recurring priming, oil delivery is instant after the first start-up, protecting the bearings and gears from premature wear.

- Easy Maintenance: whilst piping is inside the gearbox, all relevant maintenance components including filter, grease nipples and instruments are located externally in a single and easily accessible location. Several inspection openings are provided in convenient locations.

- Fully integrated filter and instruments: minimises the risk of damage and leakage.

- DriveRadar® ready: all mounting provisions for DriveRadar® instruments and edge processing unit are integrated. This enables predictive maintenance of your X.e Agitator and Mixer Drive via digital twin.

SEW-EURODRIVE, a global leader in mechatronic transmission systems and motor control electronics based in Germany, offers a wide range of integrated solutions. These include geared motors and gear units, high torque industrial gear units, high efficiency motors, electronic frequency inverters and servo drive systems.

SEW-EURODRIVE’s Australian division calls Melbourne home, with additional sales and service facilities in Sydney, Brisbane, Mackay, Perth, Adelaide and Newcastle. The company services a wide range of clients across Australia, from big corporate entities to smaller local enterprises.

For more info on the X.e Agitator and Mixer Drive or any other products and services, contact SEW-EURODRIVE via their website www.sew-eurodrive.com.au