Australia’s Largest Shotcrete Provider

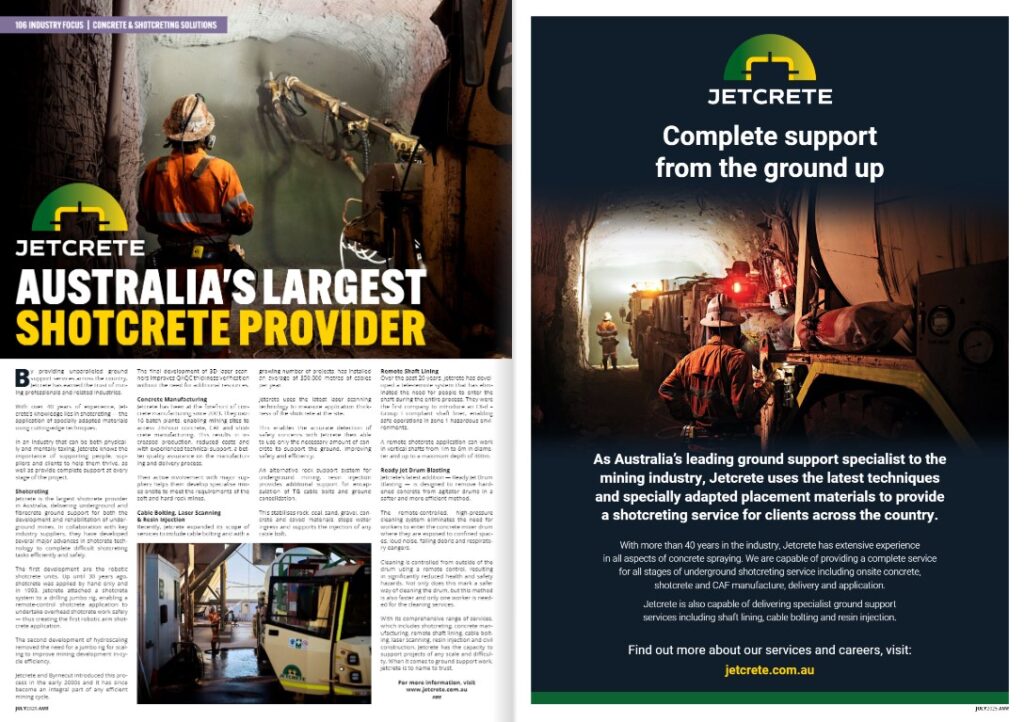

By providing unparalleled ground support services across the country, Jetcrete has earned the trust of mining professionals and related industries. With over 40 years of experience, Jetcrete’s knowledge lies in shotcreting — the application of specially adapted materials using cutting-edge techniques.

In an industry that can be both physically and mentally taxing, Jetcrete knows the importance of supporting people, suppliers and clients to help them thrive, as well as provide complete support at every stage of the project.

Shotcreting

Jetcrete is the largest shotcrete provider in Australia, delivering underground and fibrecrete ground support for both the development and rehabilitation of underground mines. In collaboration with key industry suppliers, they have developed several major advances in shotcrete technology to complete difficult shotcreting tasks efficiently and safely.

The first development are the robotic shotcrete units. Up until 30 years ago, shotcrete was applied by hand only and in 1993, Jetcrete attached a shotcrete system to a drilling jumbo rig, enabling a remote-control shotcrete application to undertake overhead shotcrete work safely — thus creating the first robotic arm shotcrete application.

The second development of hydroscaling removed the need for a jumbo rig for scaling to improve mining development in-cycle efficiency. Jetcrete and Byrnecut introduced this process in the early 2000s and it has since become an integral part of any efficient mining cycle.

The final development of 3D laser scanners improves QAQC thickness verification without the need for additional resources.

Concrete Manufacturing

Jetcrete has been at the forefront of concrete manufacturing since 2003. They own 16 batch plants, enabling mining sites to access 24-hour concrete, CAF and shotcrete manufacturing. This results in increased production, reduced costs and with experienced technical support, a better quality assurance on the manufacturing and delivery process.

Their active involvement with major suppliers helps them develop specialise mixes onsite to meet the requirements of the soft and hard rock mines.

Cable Bolting, Laser Scanning & Resin Injection

Recently, Jetcrete expanded its scope of services to include cable bolting and with a growing number of projects, has installed an average of 350,000 metres of cables per year.

Jetcrete uses the latest laser scanning technology to measure application thickness of the shotcrete at the site. This enables the accurate detection of safety concerns with Jetcrete then able to use only the necessary amount of concrete to support the ground, improving safety and efficiency.

An alternative rock support system for underground mining, resin injection provides additional support for encapsulation of TG cable bolts and ground consolidation. This stabilises rock, coal, sand, gravel, concrete and caved materials, stops water ingress and supports the injection of any cable bolt.

Remote Shaft Lining

Over the past 20 years, Jetcrete has developed a tele-remote system that has eliminated the need for people to enter the shaft during the entire process. They were the first company to introduce an EX-d – Group I compliant shaft liner, enabling safe operations in zone 1 hazardous environments.

A remote shotcrete application can work in vertical shafts from 1m to 6m in diameter and up to a maximum depth of 400m.

Ready Jet Drum Blasting

Jetcrete’s latest addition — Ready Jet Drum Blasting — is designed to remove hardened concrete from agitator drums in a safter and more efficient method. The remote-controlled, high-pressure cleaning system eliminates the need for workers to enter the concrete mixer drum where they are exposed to confined spaces, loud noise, falling debris and respiratory dangers.

Cleaning is controlled from outside of the drum using a remote control, resulting in significantly reduced health and safety hazards. Not only does this mark a safer way of cleaning the drum, but this method is also faster and only one worker is needed for the cleaning services. With its comprehensive range of services, which includes shotcreting, concrete manufacturing, remote shaft lining, cable bolting, laser scanning, resin injection and civil construction, Jetcrete has the capacity to support projects of any scale and difficulty. When it comes to ground support work, Jetcrete is to name to trust.

For more information, visit www.jetcrete.com.au.