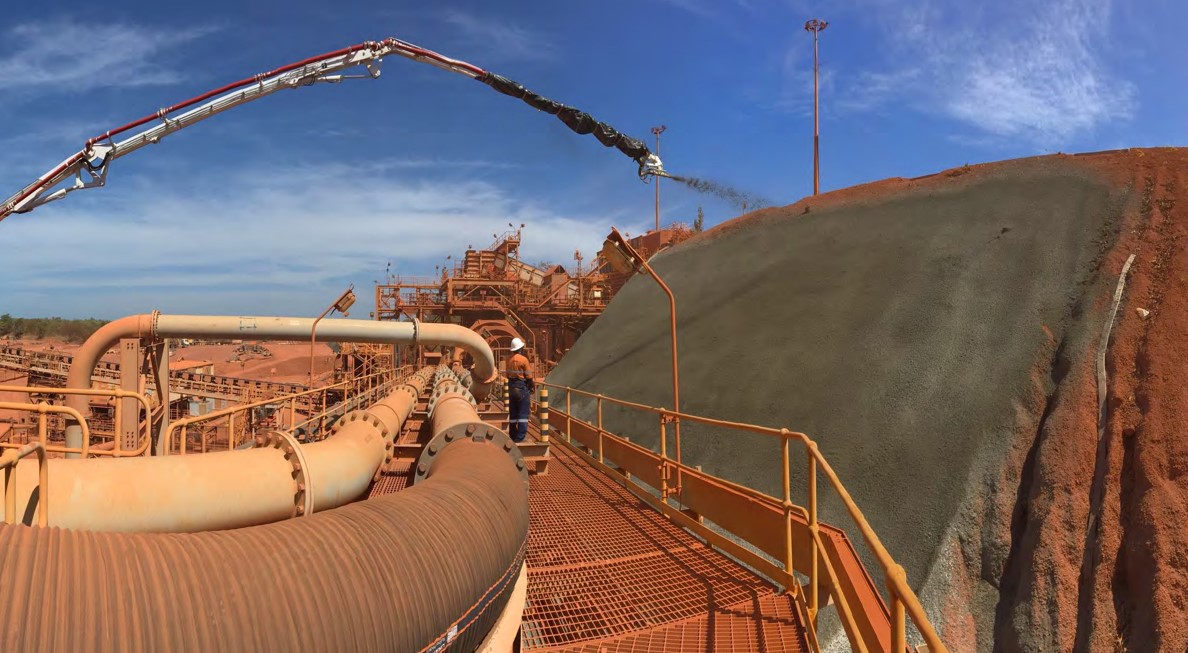

Concrete pumping with precision

With over 50 years in the construction industry, it’s no surprise that Meales Concrete Pumping has cemented its reputation as Australia’s largest and most experienced concrete pumping specialist. Since its first pump, the company has built a reputation for cutting-edge mobile and stationary concrete solutions that are sought all over the country for large-scale infrastructure, high-rise developments, and government projects.

Meales operates an extensive branch network that spans Queensland, New South Wales, Western Australia, the Northern Territory and beyond. This is backed by a fleet of plant and equipment to meet the tough demands of the

heavy industries it serves, particularly mining, LNG and renewable energy assets.

With a proven track record on iconic projects such as the Perth Children’s Hospital, the Victorian Desalination Plant, and the South Flank Mine, the pumping specialists’ ability to handle challenging and large-scale projects makes them a trusted partner developers and contractors.

Meales operates the largest fleet of mobile concrete pumps in the southern hemisphere with over 165 units ranging from 17 to 70 metres. This includes high-capacity pumps capable of delivering up to 200 cubic meters of concrete per hour, which provides a high degree of flexibility for projects of all scales. The company also offers mobile concrete boom pumps, high-pressure ground-line pumps, line pumps, and specialised equipment for unique applications like shotcreting and tunnelling.

But it’s the unique approach to safety that takes Meales Concrete Pumping to new heights.

“The key benefit is removing the risk of injury by physically separating workers from the hazards associated with traditional construction and maintenance methods,” said Meales Depot Manager Jack Lucas.

“The capability of our robotic boom units combined with their remotely controlled, precise operation essentially removes people from hazardous materials and workspaces.”

The company also adds value to customer sites by reducing downtime and completing construction and maintenance works far quicker than traditional methods.

“We add considerable production and output value, which in-turn minimises production disruption and significantly reduces shutdown times,” added Lucas.

“Our concreting methods create opportunities for our customers to conduct preventative maintenance more frequently, which minimises forced and unplanned shutdowns.”

Meales’ services extend beyond equipment hire, encompassing experienced operator teams, project management, installation, and dismantling of concrete pumping systems. Whether for major infrastructure projects like the Brisbane Airport Link or specialised projects such as wind farm construction, the company tailors its solutions to meet complex jobs safely and efficiently.

For more information or to discuss your next project, visit www.meales.com.au/