MineGlow: A decade of lighting the way for miners

Innovating LED lighting solutions for safer, more efficient operations

MineGlow, an Australian pioneer in industrial-grade LED strip lighting, is in its 10th year of revolutionising LED STRIP LIGHTING solutions for mining and heavy industrial environments. Over the past decade, MineGlow has become synonymous with safety, reliability and innovation for industrial workplace lighting.

Lighting the path to safety

MineGlow’s journey began in 2014, when founders Roy and Carinne Pater identified a critical need for proper lighting in underground mining operations. Poor lighting not only compromises safety but impacts worker productivity and well-being. Traditional lighting systems require frequent maintenance, diverting resources and adding costs to mining operations.

Witnessing firsthand the challenges miners faced during his time at underground operations throughout Australia and Africa, Mr Pater saw how much poor lighting was hindering not only the safety and productivity of workers, but also their health and wellbeing.

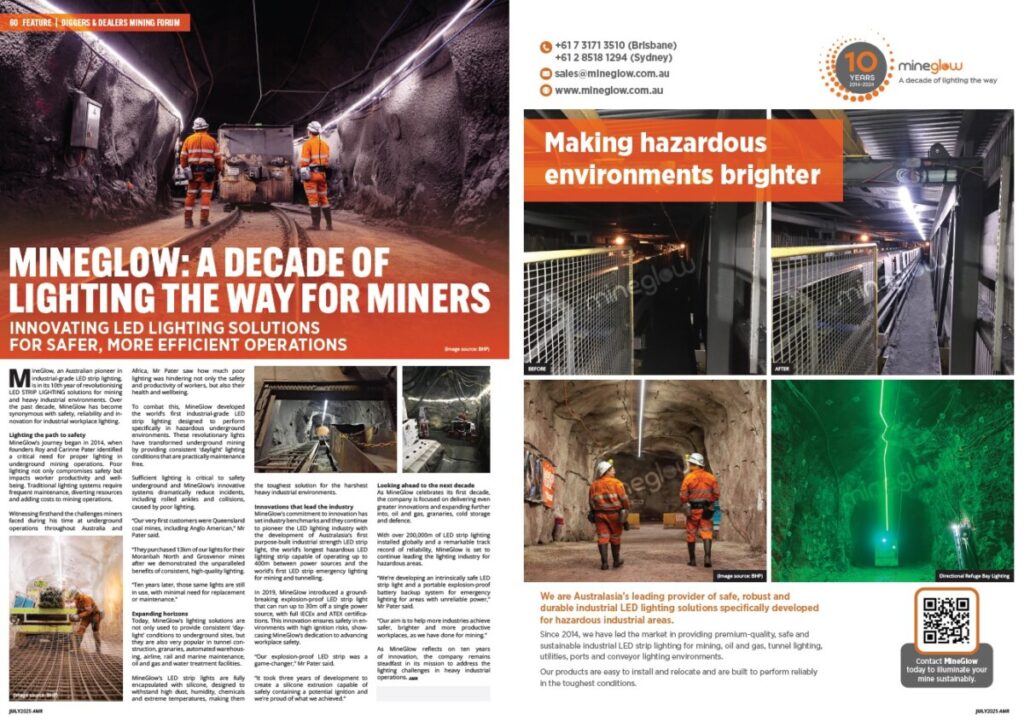

To combat this, MineGlow developed the world’s first industrial-grade LED strip lighting designed to perform specifically in hazardous underground environments. These revolutionary lights have transformed underground mining by providing consistent ‘daylight’ lighting conditions that are practically maintenance free.

Sufficient lighting is critical to safety underground and MineGlow’s innovative systems dramatically reduce incidents, including rolled ankles and collisions, caused by poor lighting.

“Our very first customers were Queensland coal mines, including Anglo American,” Mr Pater said.

“They purchased 13km of our lights for their Moranbah North and Grosvenor mines after we demonstrated the unparalleled benefits of consistent, high-quality lighting.

“Ten years later, those same lights are still in use, with minimal need for replacement or maintenance.”

Expanding horizons

Today, MineGlow’s lighting solutions are not only used to provide consistent ‘daylight’ conditions to underground sites, but they are also very popular in tunnel construction, granaries, automated warehousing, airline, rail and marine maintenance, oil and gas and water treatment facilities.

MineGlow’s LED strip lights are fully encapsulated with silicone, designed to withstand high dust, humidity, chemicals and extreme temperatures, making them the toughest solution for the harshest heavy industrial environments.

Innovations that lead the industry

MineGlow’s commitment to innovation has set industry benchmarks and they continue to pioneer the LED lighting industry with the development of Australasia’s first purpose-built industrial strength LED strip light, the world’s longest hazardous LED lighting strip capable of operating up to 400m between power sources and the world’s first LED strip emergency lighting for mining and tunnelling

In 2019, MineGlow introduced a groundbreaking explosion-proof LED strip light that can run up to 30m off a single power source, with full IECEx and ATEX certifications. This innovation ensures safety in environments with high ignition risks, showcasing MineGlow’s dedication to advancing workplace safety.

“Our explosion-proof LED strip was a game-changer,” Mr Pater said.

“It took three years of development to create a silicone extrusion capable of safely containing a potential ignition and we’re proud of what we achieved.”

Looking ahead to the next decade

As MineGlow celebrates its first decade, the company is focused on delivering even greater innovations and expanding further into, oil and gas, granaries, cold storage and defence.

With over 200,000m of LED strip lighting installed globally and a remarkable track record of reliability, MineGlow is set to continue leading the lighting industry for hazardous areas.

“We’re developing an intrinsically safe LED strip light and a portable explosion-proof battery backup system for emergency lighting for areas with unreliable power,” Mr Pater said.

“Our aim is to help more industries achieve safer, brighter and more productive workplaces, as we have done for mining.”

As MineGlow reflects on ten years of innovation, the company remains steadfast in its mission to address the lighting challenges in heavy industrial operations.