MOXI’s EEHA Toolkit

In the mining industry, potential dangers are as ubiquitous as the rocks that are excavated. Ensuring that all electrical equipment adheres to stringent safety standards and regulations is a monumental task. It is here that MOXI enters the fray with its Electrical Equipment in Hazardous Areas (EEHA) audit checklist and inspection procedure.

Crafted to assist mining companies in successfully navigating the complex terrain of safety compliance, the focus is firmly on protecting the wellbeing of workers and ensuring smooth operational continuity.

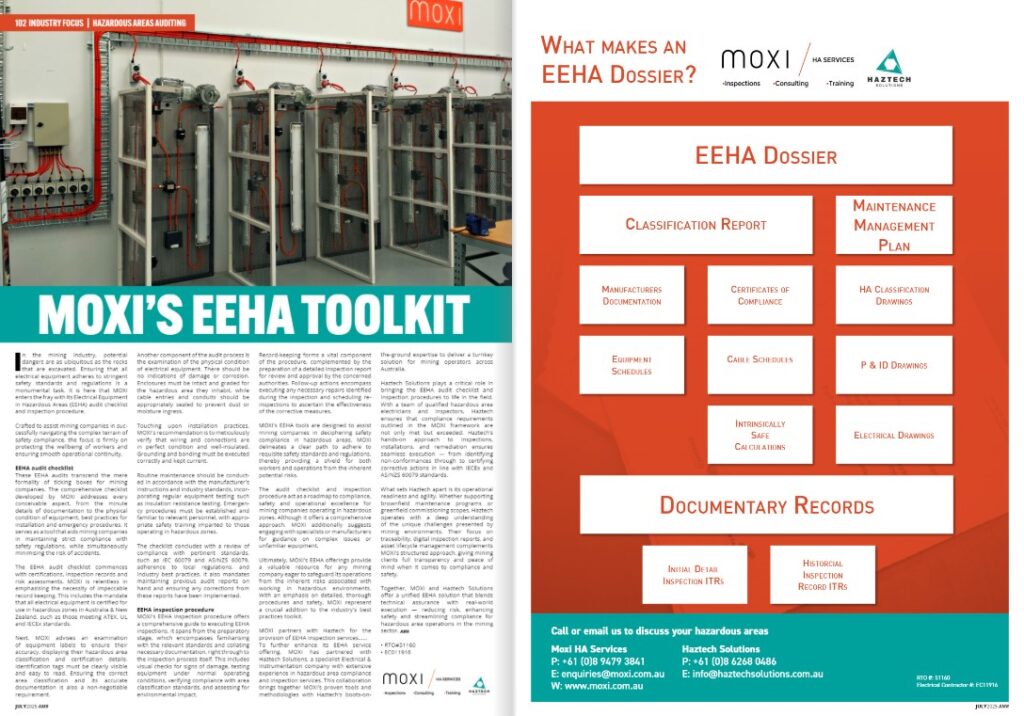

EEHA audit checklist

These EEHA audits transcend the mere formality of ticking boxes for mining companies. The comprehensive checklist developed by MOXI addresses every conceivable aspect, from the minute details of documentation to the physical condition of equipment, best practices for installation and emergency procedures. It serves as a tool that aids mining companies in maintaining strict compliance with safety regulations, while simultaneously minimising the risk of accidents.

The EEHA audit checklist commences with certifications, inspection records and risk assessments. MOXI is relentless in emphasising the necessity of impeccable record keeping. This includes the mandate that all electrical equipment is certified for use in hazardous zones in Australia & New Zealand, such as those meeting ATEX, UL and IECEx standards.

Next, MOXI advises an examination of equipment labels to ensure their accuracy, displaying their hazardous area classification and certification details. Identification tags must be clearly visible and easy to read. Ensuring the correct area classification and its accurate documentation is also a non-negotiable requirement.

Another component of the audit process is the examination of the physical condition of electrical equipment. There should be no indications of damage or corrosion. Enclosures must be intact and graded for the hazardous area they inhabit, while cable entries and conduits should be appropriately sealed to prevent dust or moisture ingress.

Touching upon installation practices, MOXI’s recommendation is to meticulously verify that wiring and connections are in perfect condition and well-insulated. Grounding and bonding must be executed correctly and kept current.

Routine maintenance should be conducted in accordance with the manufacturer’s instructions and industry standards, incorporating regular equipment testing such as insulation resistance testing. Emergency procedures must be established and familiar to relevant personnel, with appropriate safety training imparted to those operating in hazardous zones.

The checklist concludes with a review of compliance with pertinent standards, such as IEC 60079 and AS/NZS 60079, adherence to local regulations, and industry best practices. It also mandates maintaining previous audit reports on hand and ensuring any corrections from these reports have been implemented.

EEHA inspection procedure

MOXI’s EEHA inspection procedure offers a comprehensive guide to executing EEHA inspections. It spans from the preparatory stage, which encompasses familiarising with the relevant standards and collating necessary documentation, right through to the inspection process itself. This includes visual checks for signs of damage, testing equipment under normal operating conditions, verifying compliance with area classification standards, and assessing for environmental impact.

Record-keeping forms a vital component of the procedure, complemented by the preparation of a detailed inspection report for review and approval by the concerned authorities. Follow-up actions encompass executing any necessary repairs identified during the inspection and scheduling re-inspections to ascertain the effectiveness of the corrective measures.

MOXI’s EEHA tools are designed to assist mining companies in deciphering safety compliance in hazardous areas. MOXI delineates a clear path to adhere to requisite safety standards and regulations, thereby providing a shield for both workers and operations from the inherent potential risks.

The audit checklist and inspection procedure act as a roadmap to compliance, safety and operational excellence for mining companies operating in hazardous zones. Although it offers a comprehensive approach, MOXI additionally suggests engaging with specialists or manufacturers for guidance on complex issues or unfamiliar equipment.

Ultimately, MOXI’s EEHA offerings provide a valuable resource for any mining company eager to safeguard its operations from the inherent risks associated with working in hazardous environments. With an emphasis on detailed, thorough procedures and safety, MOXI represent a crucial addition to the industry’s best practices toolkit.

MOXI partners with Haztech for the provision of EEHA Inspection services……

To further enhance its EEHA service offering, MOXI has partnered with Haztech Solutions, a specialist Electrical & Instrumentation company with extensive experience in hazardous area compliance and inspection services. This collaboration brings together MOXI’s proven tools and methodologies with Haztech’s boots-on-the-ground expertise to deliver a turnkey solution for mining operators across Australia.

Haztech Solutions plays a critical role in bringing the EEHA audit checklist and inspection procedures to life in the field. With a team of qualified hazardous area electricians and inspectors, Haztech ensures that compliance requirements outlined in the MOXI framework are not only met but exceeded. Haztech’s hands-on approach to inspections, installations, and remediation ensures seamless execution — from identifying non-conformances through to certifying corrective actions in line with IECEx and AS/NZS 60079 standards.

What sets Haztech apart is its operational readiness and agility. Whether supporting brownfield maintenance programs or greenfield commissioning scopes, Haztech operates with a deep understanding of the unique challenges presented by mining environments. Their focus on traceability, digital inspection reports, and asset lifecycle management complements MOXI’s structured approach, giving mining clients full transparency and peace of mind when it comes to compliance and safety.

Together, MOXI and Haztech Solutions offer a unified EEHA solution that blends technical assurance with real-world execution — reducing risk, enhancing safety and streamlining compliance for hazardous area operations in the mining sector.