Schaeffler’s OPTIME CM

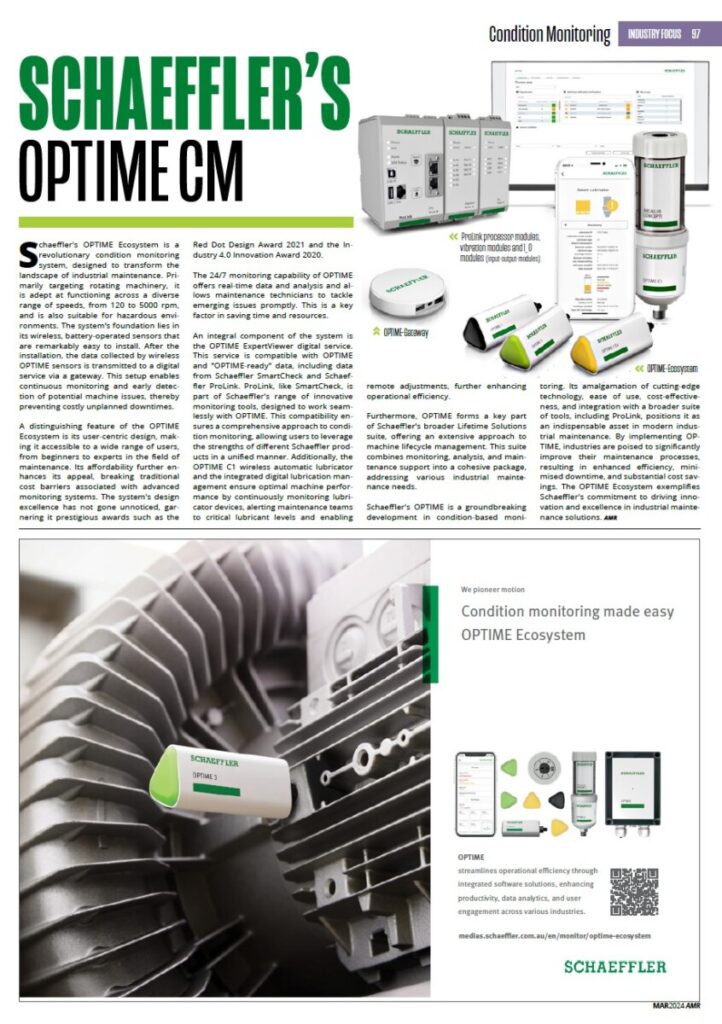

Schaeffler’s OPTIME Ecosystem is a revolutionary condition monitoring system, designed to transform the landscape of industrial maintenance. Primarily targeting rotating machinery, it is adept at functioning across a diverse range of speeds, from 120 to 5000 rpm, and is also suitable for hazardous environments. The system’s foundation lies in its wireless, battery-operated sensors that are remarkably easy to install. After the installation, the data collected by wireless OPTIME sensors is transmitted to a digital service via a gateway. This setup enables continuous monitoring and early detection of potential machine issues, thereby preventing costly unplanned downtimes.

A distinguishing feature of the OPTIME Ecosystem is its user-centric design, making it accessible to a wide range of users, from beginners to experts in the field of maintenance. Its affordability further enhances its appeal, breaking traditional cost barriers associated with advanced monitoring systems. The system’s design excellence has not gone unnoticed, garnering it prestigious awards such as the Red Dot Design Award 2021 and the Industry 4.0 Innovation Award 2020.

The 24/7 monitoring capability of OPTIME offers real-time data and analysis and allows maintenance technicians to tackle emerging issues promptly. This is a key factor in saving time and resources.

An integral component of the system is the OPTIME ExpertViewer digital service. This service is compatible with OPTIME and “OPTIME-ready” data, including data from Schaeffler SmartCheck and Schaeffler ProLink. ProLink, like SmartCheck, is part of Schaeffler’s range of innovative monitoring tools, designed to work seamlessly with OPTIME. This compatibility ensures a comprehensive approach to condition monitoring, allowing users to leverage the strengths of different Schaeffler products in a unified manner. Additionally, the OPTIME C1 wireless automatic lubricator and the integrated digital lubrication management ensure optimal machine performance by continuously monitoring lubricator devices, alerting maintenance teams to critical lubricant levels and enabling remote adjustments, further enhancing operational efficiency.

Furthermore, OPTIME forms a key part of Schaeffler’s broader Lifetime Solutions suite, offering an extensive approach to machine lifecycle management. This suite combines monitoring, analysis, and maintenance support into a cohesive package, addressing various industrial maintenance needs.

Schaeffler’s OPTIME is a groundbreaking development in condition-based monitoring. Its amalgamation of cutting-edge technology, ease of use, cost-effectiveness, and integration with a broader suite of tools, including ProLink, positions it as an indispensable asset in modern industrial maintenance. By implementing OPTIME, industries are poised to significantly improve their maintenance processes, resulting in enhanced efficiency, minimised downtime, and substantial cost savings. The OPTIME Ecosystem exemplifies Schaeffler’s commitment to driving innovation and excellence in industrial maintenance solutions.